About Laser

- Home

- > Laser Welding Robotic solution for Impeller welding

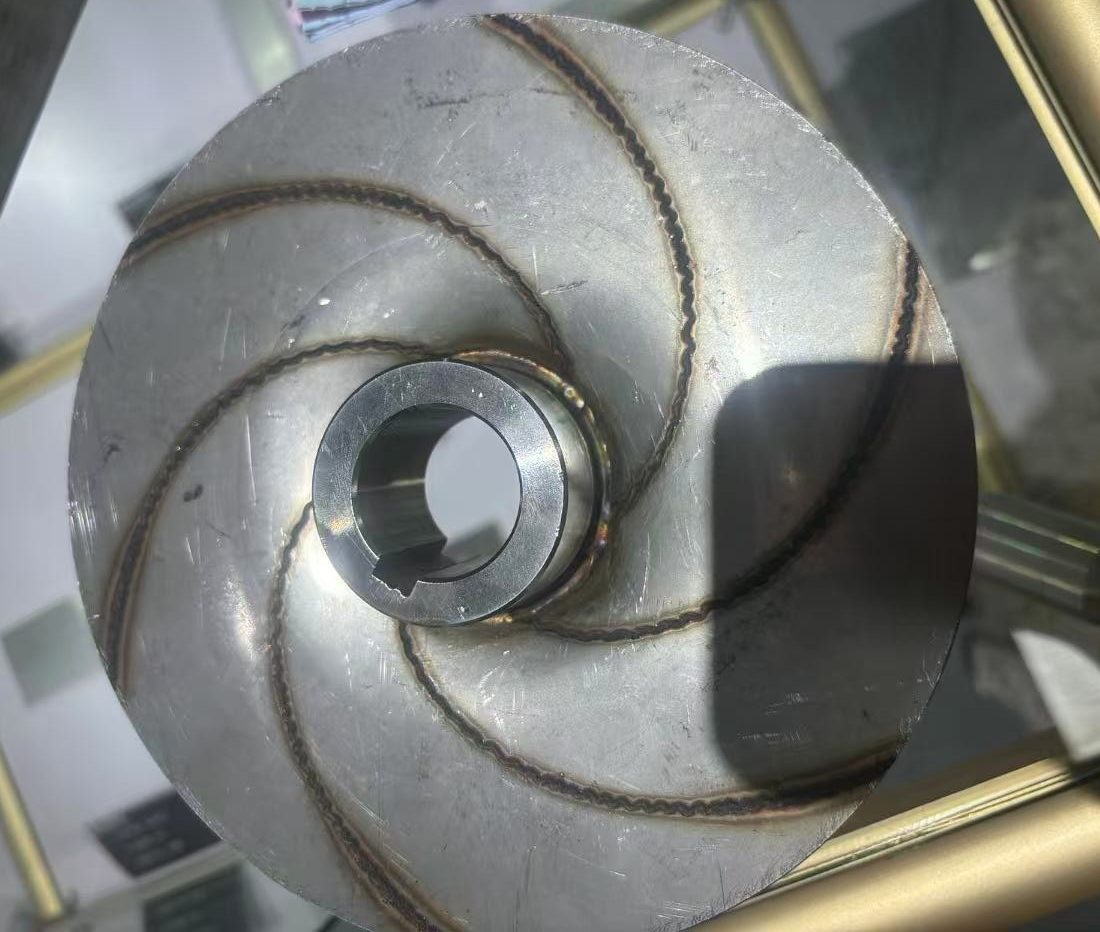

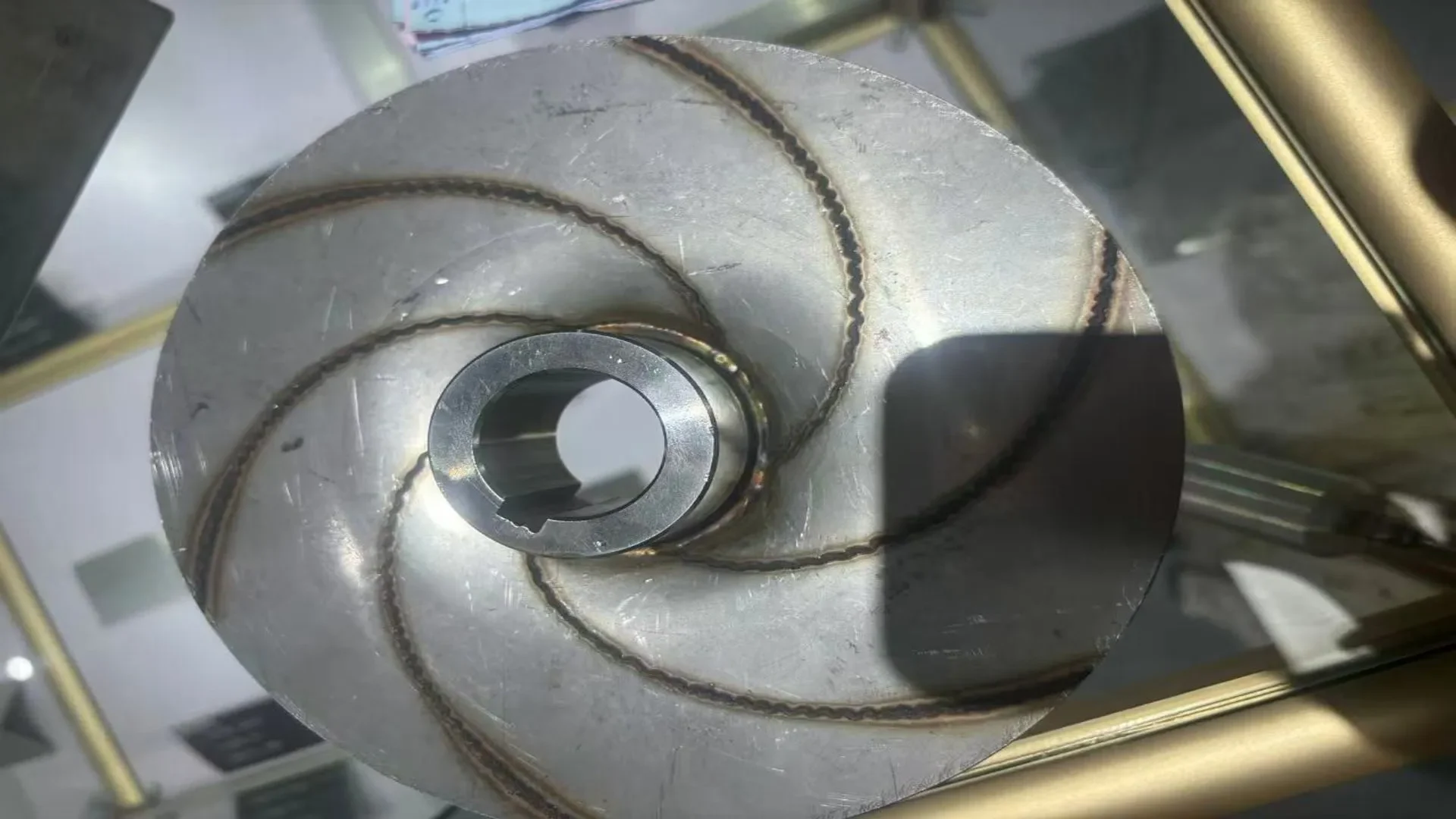

Laser Welding Robot solution for Impeller Welding

Why is Laser Welding Robot solution suitable for impeller product?

– Minimal Heat Distortion

Laser welding uses a focused heat beam, which reduces the heat-affected area, lowering the risk of impeller distortion during welding and ensuring proper function.

– High Precision

The laser beam can be precisely focused on the weld joint, allowing for accurate control and creating clean, consistent welds on complex impeller shapes.

– Small Heat-Affected Zone (HAZ)

The small HAZ around the weld minimizes material degradation and preserves the mechanical properties of the impeller material.

– High Welding Speed

Laser welding allows for rapid welding, making it efficient for high-volume impeller production.

– Ability to Weld Dissimilar Materials

Depending on the laser type, laser welding can join different metals used in impeller construction.

Our TrueSyn system features advantages as below:

– Safe and reliable

The system has the ability to resist interference such as arc light, smoke, splash, etc., to ensure stable work in harsh environments.

– Easy operation

We provide a user-friendly interface that requires no specialized professional welding robot operation experience, reducing the difficulty of operation.

High production efficiency:

The system automates and smartens the welding process, significantly reducing manual operations and improving production efficiency.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.