About Laser

- Home

- > Laser Cutting

3D robotic cutting

The core value of 3D robotic cutting lies in its ability to handle complex curved surfaces, three-dimensional structures, and flexible production requirements. Although its absolute accuracy is slightly lower than that of traditional five-axis laser cutter, its advantages—such as lower cost, larger workspace, and flexible programming—make it an indispensable solution in fields like automotive, aerospace, and custom manufacturing. Especially for irregular and non-standard parts ,its high flexibility and strong adaptability are its big advantages; Through multi-axis coordination, it can freely process complex curved surfaces, eliminating the need for specialized tooling. Offline programming enables rapid response to small-batch custom demands, significantly reducing production preparation time.

The impact of robot accuracy on cutting:

Robot accuracy has a significant impact on laser cutting, directly affecting processing quality, efficiency, and applicable range.

Specific problems caused by insufficient accuracy:

1. Geometric image distortion

2. The quality of the incision has deteriorated.

Increased surface roughness: Insufficient precision can cause the laser focus position to shift, leading to uneven energy distribution and resulting in burrs and slag on the cut surface.

3. Process limitations

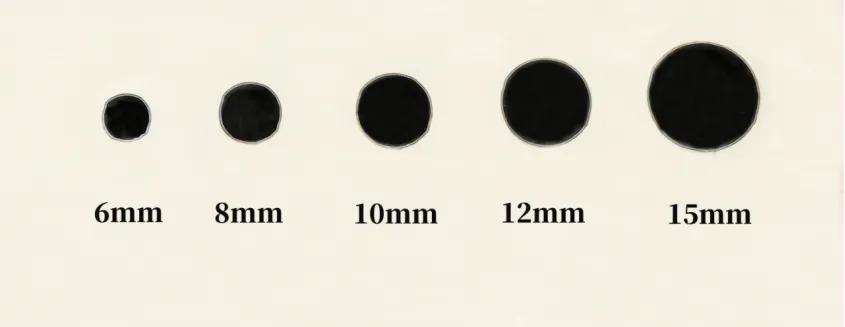

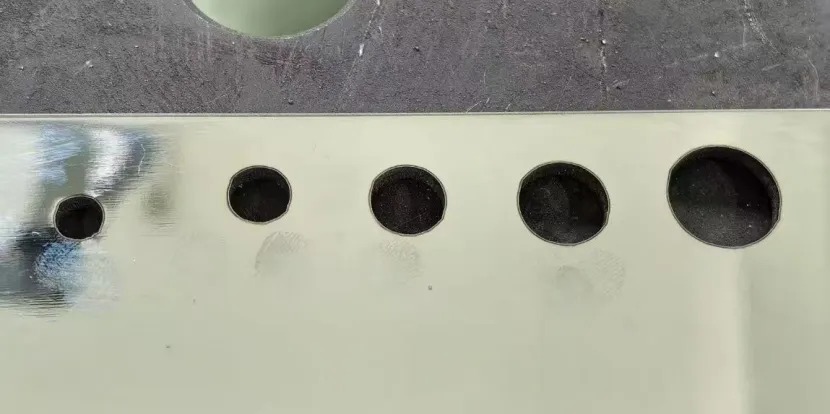

Achieving high-precision machining of features such as micro-holes and narrow slits is difficult and usually requires a higher-precision gantry-type laser cutting machine.

Conclusion:

We chose high-precision FANUC brand robots. The FANUC 20iB robot is a mature and reliable 3D cutting solution, especially suitable for industries requiring long-term continuous operation and medium precision (such as automotive parts and metal products).

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.