About Laser

- Home

- > Integrated Robotic Welding Cell – with Automatic Loading/Unloading and Positioning System

Integrated Robotic Laser Welding Cell

System Components and Function Description

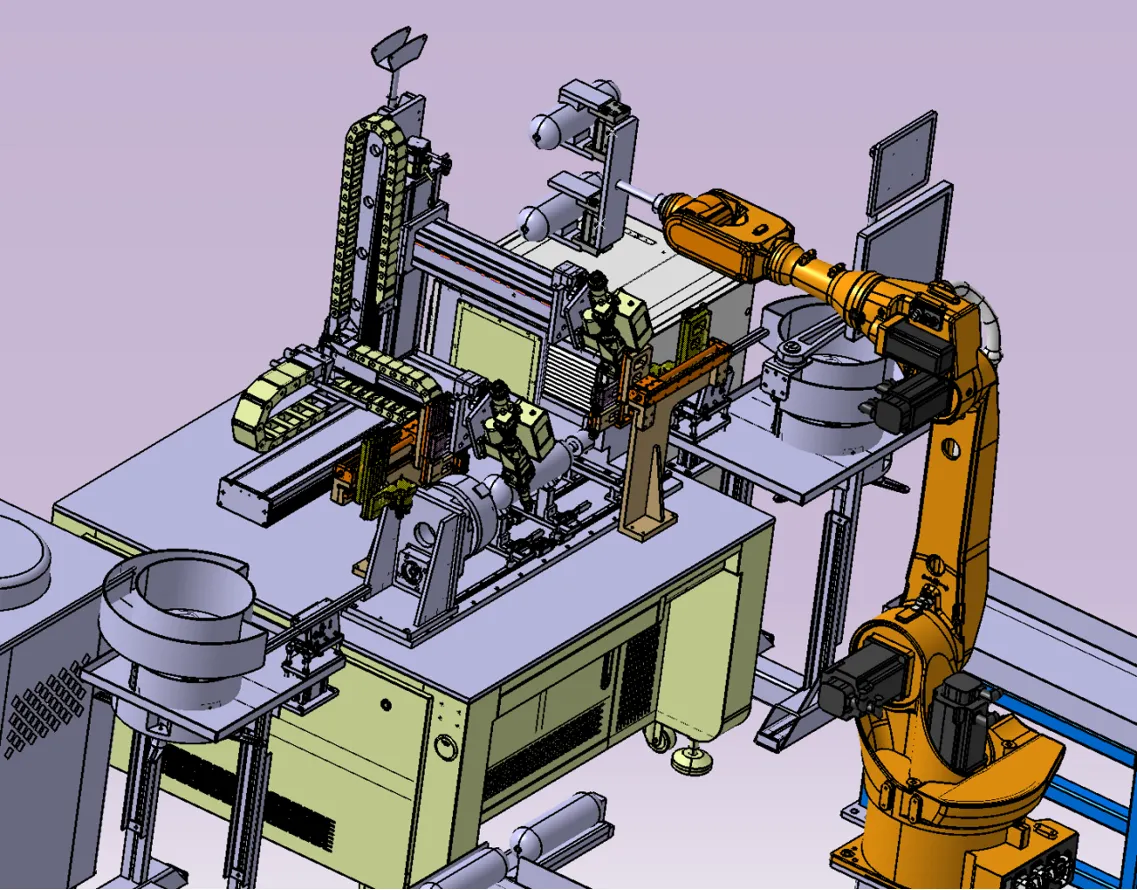

1. Loading and unloading unit

- Robot system: Used solely for workpiece gripping and handling, enabling fully automatic transfer from the loading platform to the fixture and then to the unloading platform.

- Vibratory feeder + loading platform: Automatically sorts and conveys workpieces to be welded, improving the consistency of the loading cycle.

- Robot gripper: Customized according to the workpiece shape to ensure stable and reliable gripping.

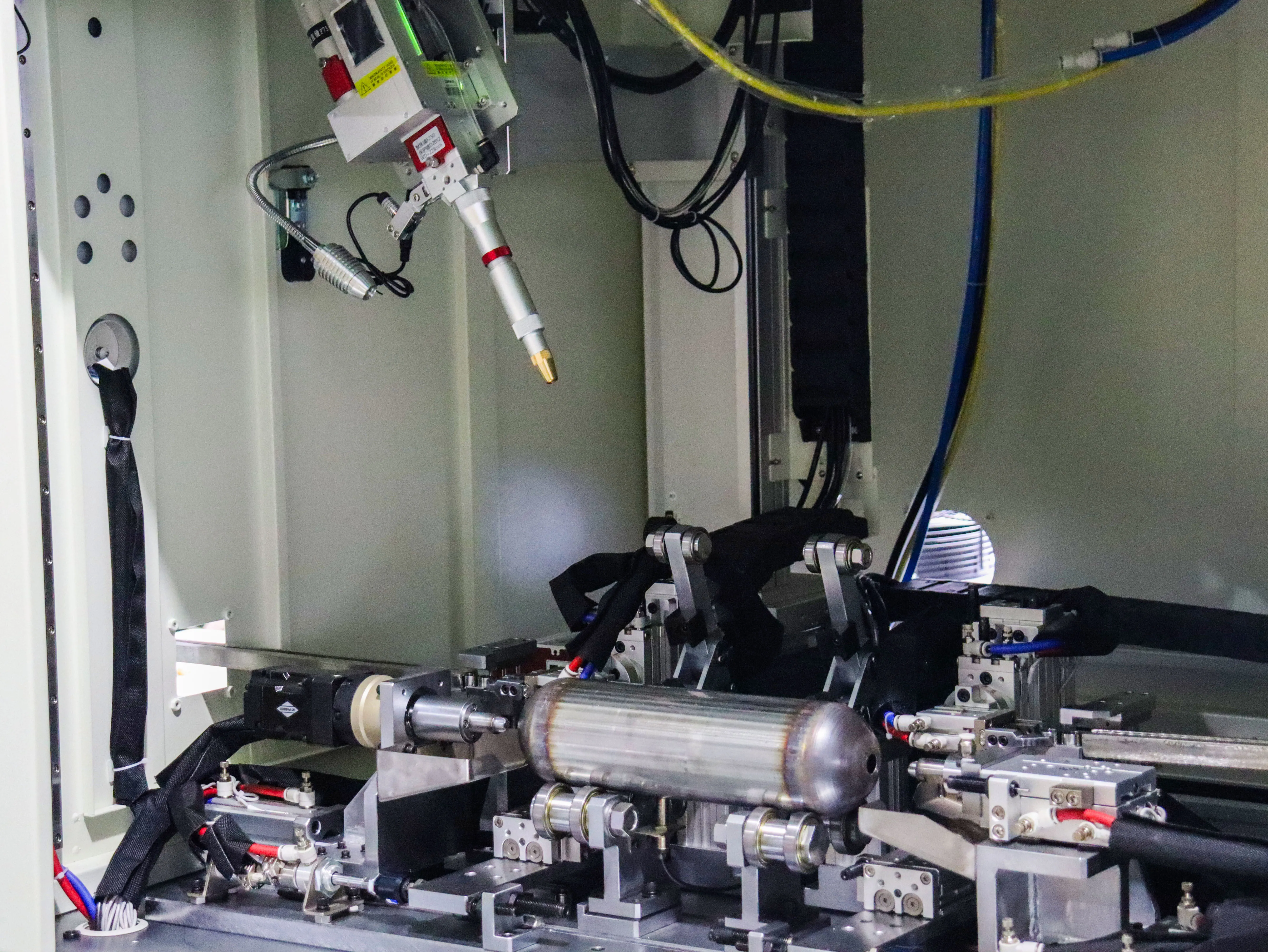

2. Welding execution unit

XYZ Three-Axis Module Workstation:

- The core welding actuator that carries the workpiece and enables precise 3-axis motion to control the welding path. Supports multi-position, multi-angle welding, ideal for workpieces requiring double-sided welding.

Rotating Welding Head:

- Mounted on the welding torch and rotatable for angle adjustment, allowing continuous double-sided welding without re-clamping the workpiece.

Laser Welding System:

- Supplied by Zhejiang Innovation Laser, integrated with a chiller for stable output, delivering a minimal heat-affected zone and high-precision welding

3. Positioning and clamping unit

Workpiece Fixturing System:

- Utilizes a pneumatic tailstock + center point + quick-release clamp structure to ensure stable clamping of the workpiece during the welding process.

- Supports quick changeover to accommodate different workpiece models.

Support Structure and Bearings:

- Provides rigid support, reducing the impact of vibration on welding quality.

4. Control System

- It integrates robot control and three-axis motion control, and supports the storage and retrieval of welding process parameters.

- It features a human-machine interface, supporting one-button start, status monitoring, and alarm notifications.

Process Flow

1.Loading: Vibratory feeder feeds parts → Robot picks up the workpiece → Places it in the fixture.

2.Positioning: Pneumatic tailstock automatically clamps the workpiece to ensure accurate positioning.

3.Welding:

- The XYZ three-axis module moves the workpiece, and the rotating welding gun completes welding on one side.

- The welding gun rotates, the three-axis module adjusts its position, and welding on the other side is completed.

4.Unloading: Welding completed → Release clamp → Robot picks up the workpiece and places it in the unloading area.

Key advantages of the solution

- One-stop service: Integrating all processes from material supply, workpiece positioning, and automated welding to equipment maintenance, eliminating the need for additional equipment and reducing customer deployment costs;

- High degree of automation: Utilizing automated equipment such as robots, three-axis modules, and vibratory feeders to reduce manual intervention and improve welding efficiency and product consistency;

- Precise and reliable welding: Ensuring accurate welding positions and stable welding quality through precise positioning and fixing with professional fixtures and accurate operation of the rotating welding head;

- Reasonable structural design: The compact layout adapts to actual workshop needs, and all equipment and mechanisms work together to optimize the production process.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.