About Laser

- Home

- > Air Tightness & Precision: Laser Welding Solution for Stainless Steel Towel Warmers

Air Tightness & Precision: Laser Welding for Stainless Steel Towel Warmers

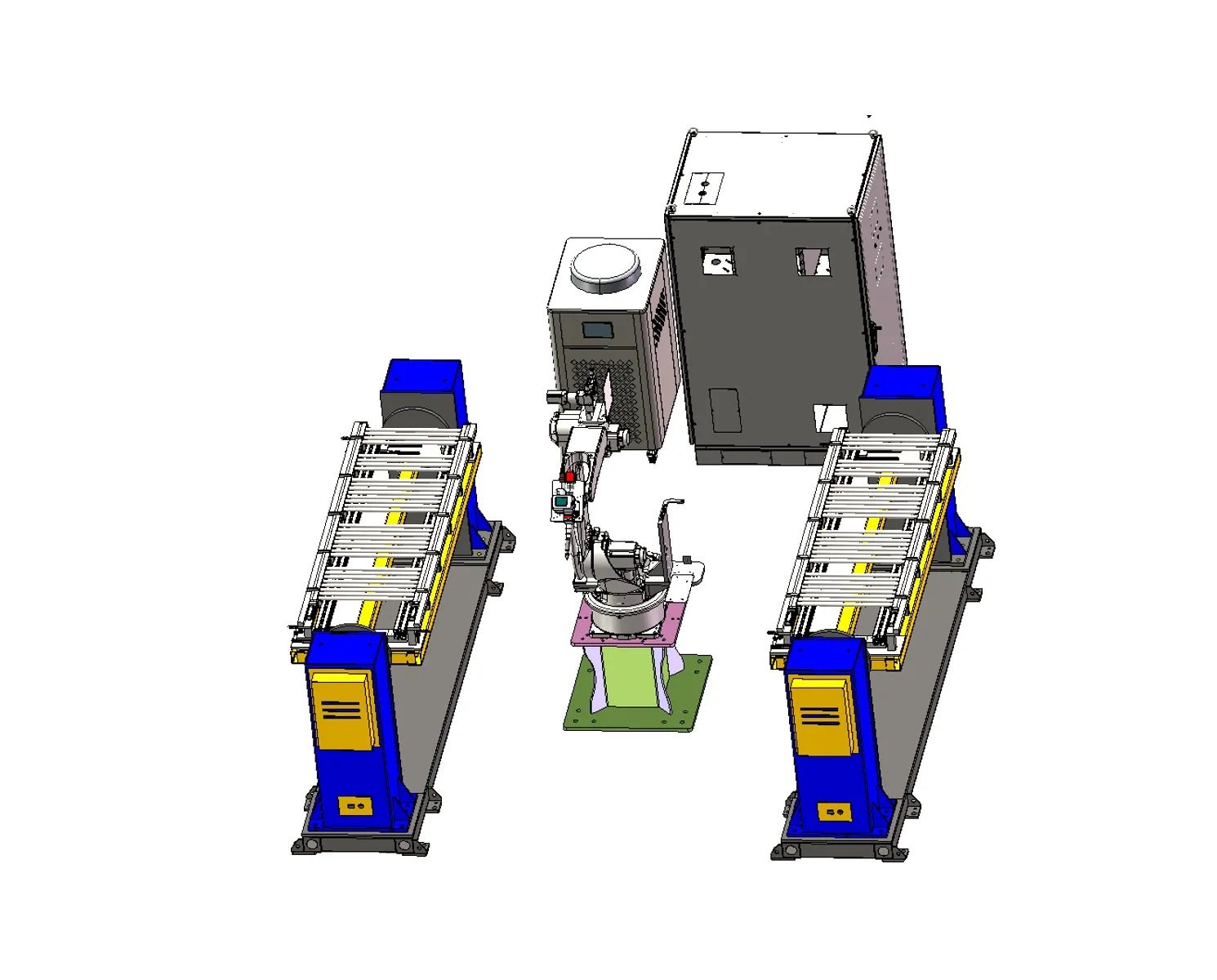

This laser welding solution is specifically designed for stainless steel towel warmers, with an applicable product size range of 600mm-1680mm in length and 300mm-600mm in width. It is compatible with different pipe structures such as horizontal round pipes and square pipes, focusing on addressing the precise welding requirements between pipes and collectors.

2. Core Composition of the Solution

Basic Support Modules

Key Equipment Configuration

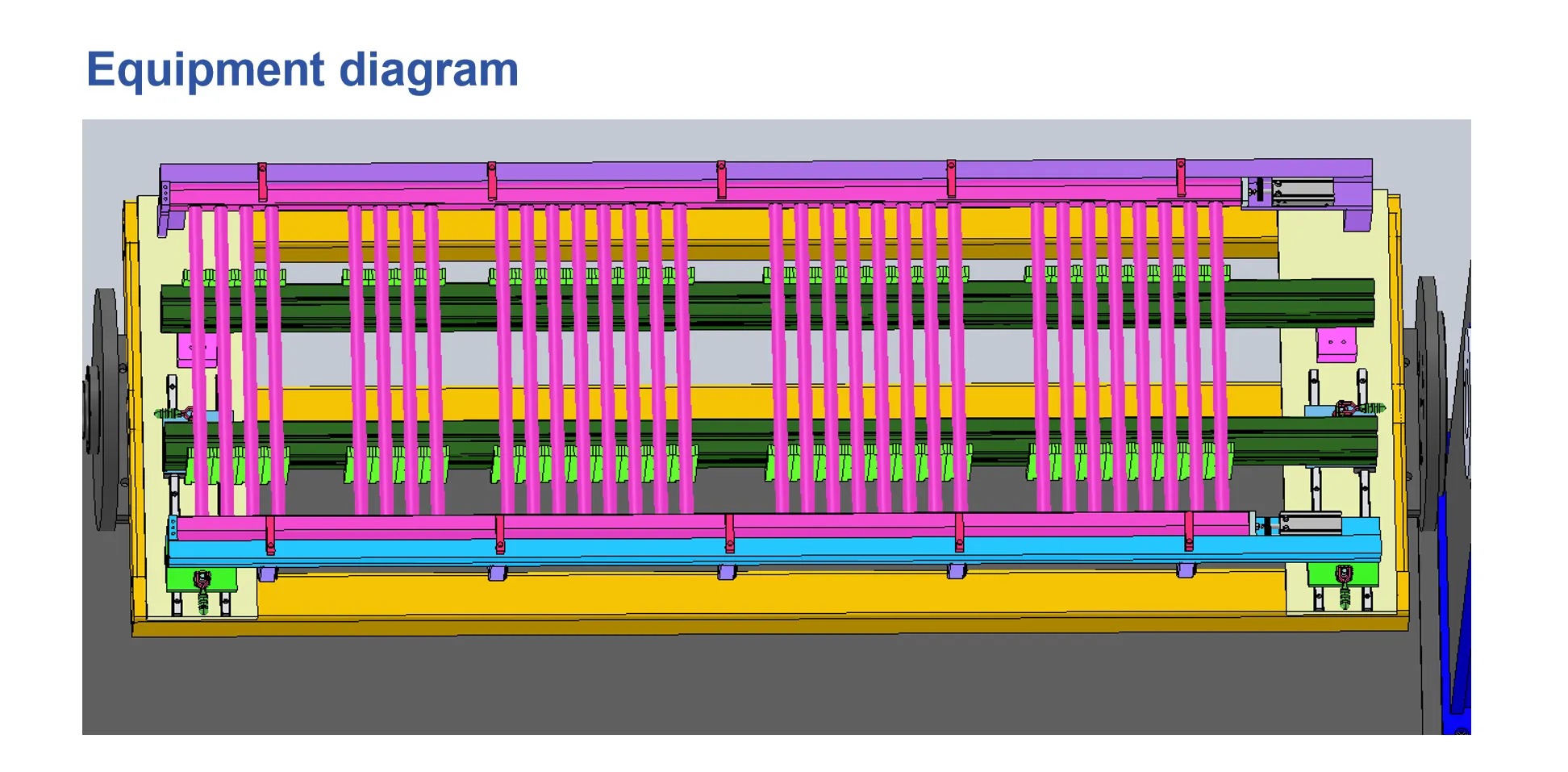

The solution integrates core equipment such as an electrical control cabinet, laser welding head, industrial robot, dual positioners, and water chiller. Among them, V-shaped blocks are used for positioning round pipes and U-shaped blocks for square pipes, ensuring precise fixation of different pipes and stable welding processes.

3. Standardized Welding Process

- Move the fixture components to the corresponding position according to the product width, and adjust the equipment length to match the product specifications;

- Arrange the fixture adjustment blocks according to the quantity and distribution of horizontal pipes;

- Place a collector on one side and insert the horizontal pipes, then install the collector on the other side to achieve precise product alignment;

- Activate the side push cylinder to lock the collector, and press the workpiece twice with the press cylinder to avoid welding deformation;

- The laser welding head completes the welding of the weld seam on one side, and the dual positioners drive the workpiece to flip for welding the weld seam on the reverse side, thus completing the entire operation.

Comparison Dimension | Traditional Arc Welding (TIG/MIG/MAG) | Laser Welding |

Heat Affected Zone & Deformation Control | Wide heat diffusion range; thin stainless steel frames prone to bending/warping, requiring extra straightening process | High-energy laser focuses on welding spots; heat affected zone is 1/5–1/10 that of arc welding; no obvious deformation for thin-walled parts |

Weld Appearance & Post-processing | Wide welds; TIG welding causes weld beads, MIG welding leads to spatter; exposed welds need manual grinding and polishing | Narrow, smooth, spatter-free welds; meets finished product appearance standards directly |

Weld Strength & Precision Adaptability | Low weld penetration control accuracy; easy to burn through or cold weld precision parts (heater tube holders, micro connectors) | Precise penetration control; dense weld structure; tensile strength 10%–20% higher than arc welding; stable welding for 0.3–2mm thin-walled parts |

Production Efficiency & Automation | High reliance on welder skills for manual TIG welding; limited single-machine capacity; frequent electrode/wire replacement | Integratable with robotic arms and vision positioning systems for unmanned continuous operation; 3–5x faster than manual TIG welding; accurate reproduction of complex welding paths |

Material Compatibility | Difficult to weld high thermal conductivity materials (aluminum alloy, copper alloy); prone to pores and cracks | Stable welding of stainless steel, carbon steel, aluminum alloy, copper alloy by adjusting power; supports heterogeneous material splicing |

Energy Consumption & Cost | Low arc energy efficiency; continuous consumption of shielding gas, electrodes and wires; high long-term costs | High energy efficiency; fiber laser welder consumes 1/3 the power of arc welding equipment; no massive wire consumption |

4. Core Advantages of the Solution

- Strong Adaptability: Equipped with adjustable fixtures and flexible size-adaptive design, it is compatible with stainless steel towel warmers of different specifications and pipe types, meeting the production needs of multi-variety, small-batch or large-batch production.

- High Degree of Automation: Integrates automated components such as industrial robots, dual positioners, and cylinder pressing systems, reducing manual intervention and human operation errors while improving welding precision and product consistency.

- Superior Welding Quality: Laser welding technology achieves narrow weld seams and small heat-affected zones with high weld density, fully meeting the core airtightness requirements of stainless steel towel warmers. Additionally, the workpiece experiences minimal deformation after welding, eliminating the need for extensive subsequent grinding.

- High Production Efficiency: Standardized process flows and quick mold change design shorten product switching time. Combined with efficient robotic welding operations, it significantly increases hourly output and reduces the production cost per unit.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.