About Laser

- Home

- > TrueSyn Customized Fixtures

TrueSyn Customized Fixtures

Workholding Fixtures in Robotic Welding Cells

In a robotic welding cell, fixtures are specialized devices designed to securely hold and position one or more workpieces for the welding process. Their primary roles are precision, safety, and efficiency.

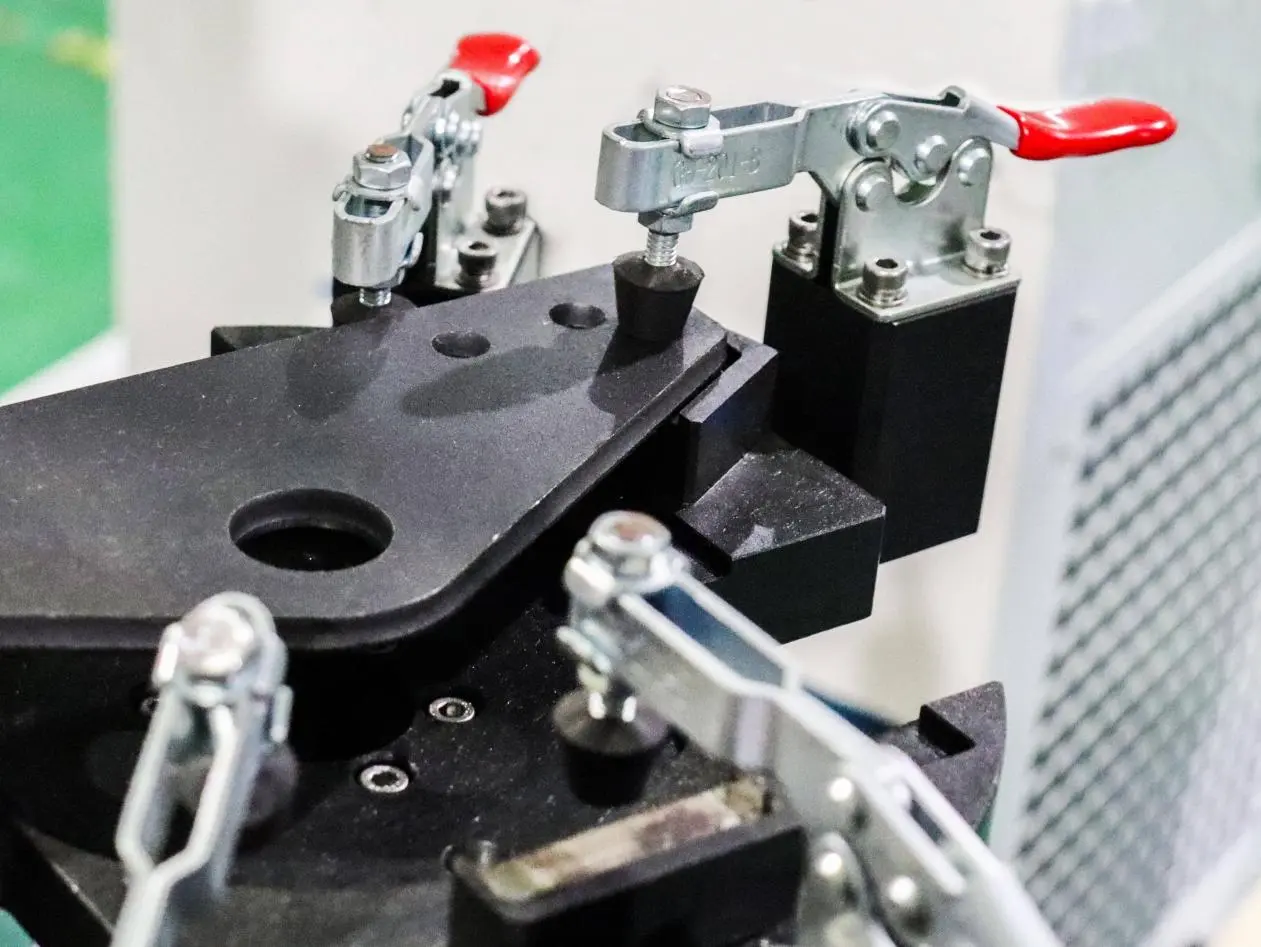

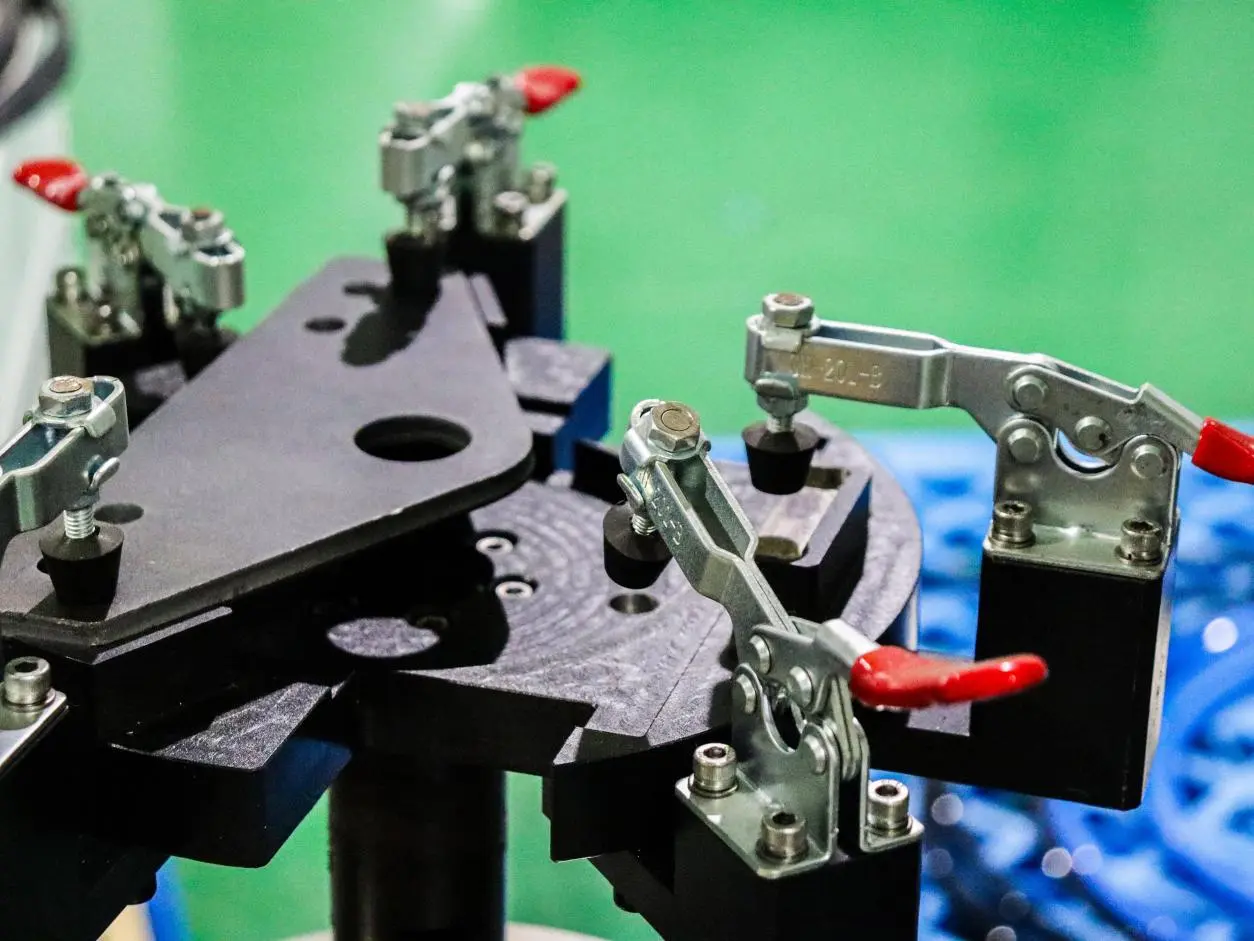

Type 1:Manual Clamping Fixtures

Types: Swing clamps, push clamps, toe clamps, and quick-release levers.

Functions: To securely hold the workpiece against locators with human-operated force. They are simple, reliable, and cost-effective for low to medium-volume production.

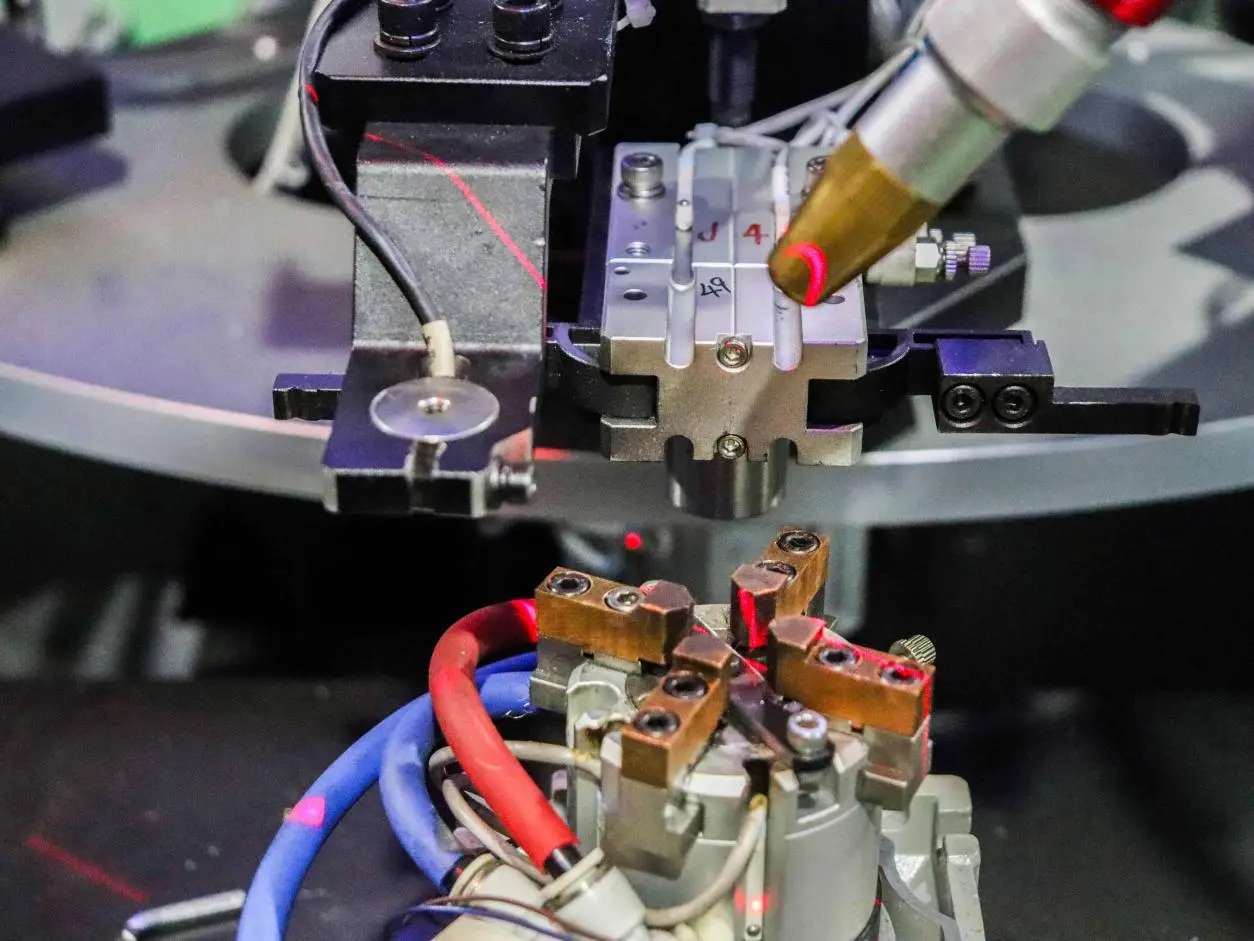

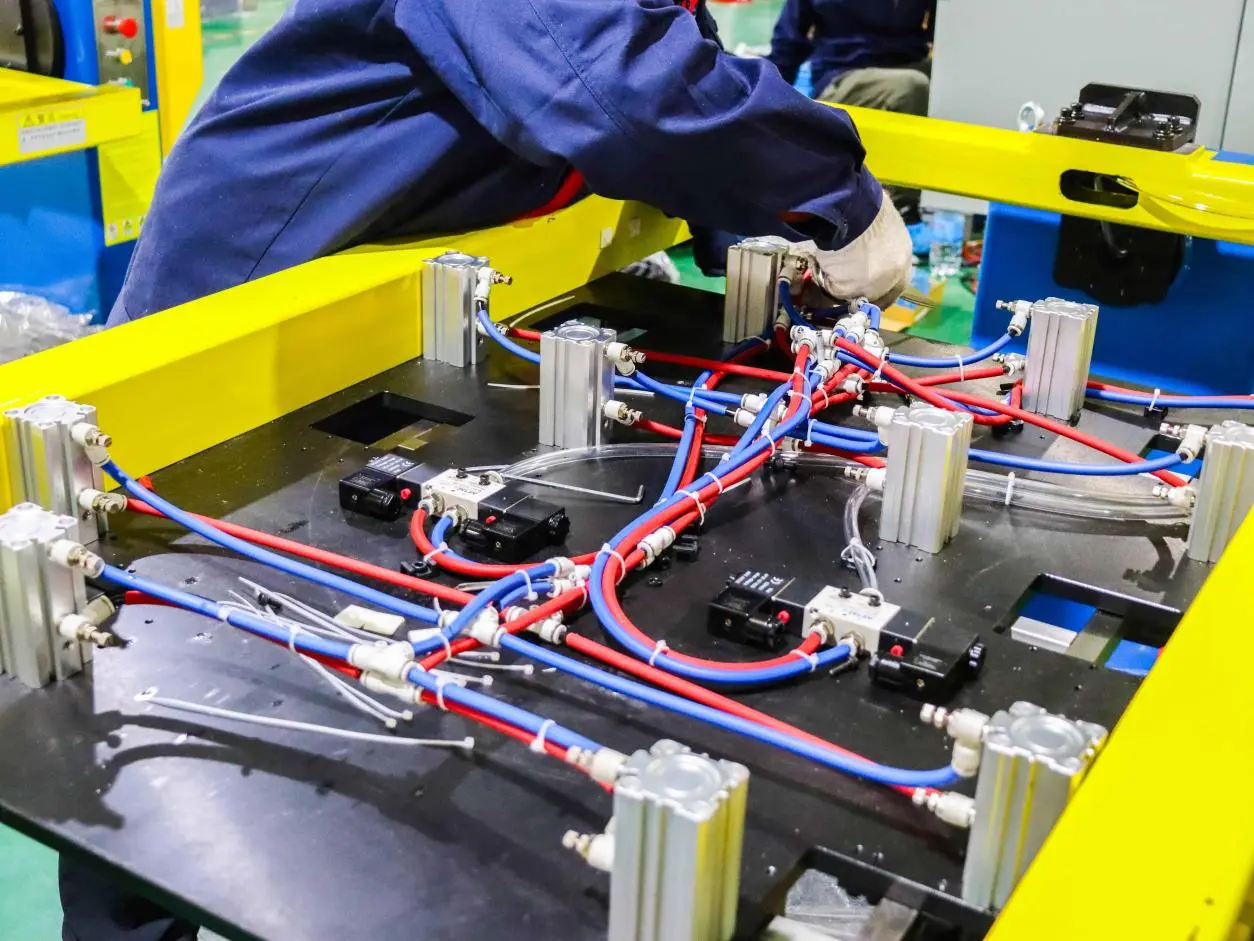

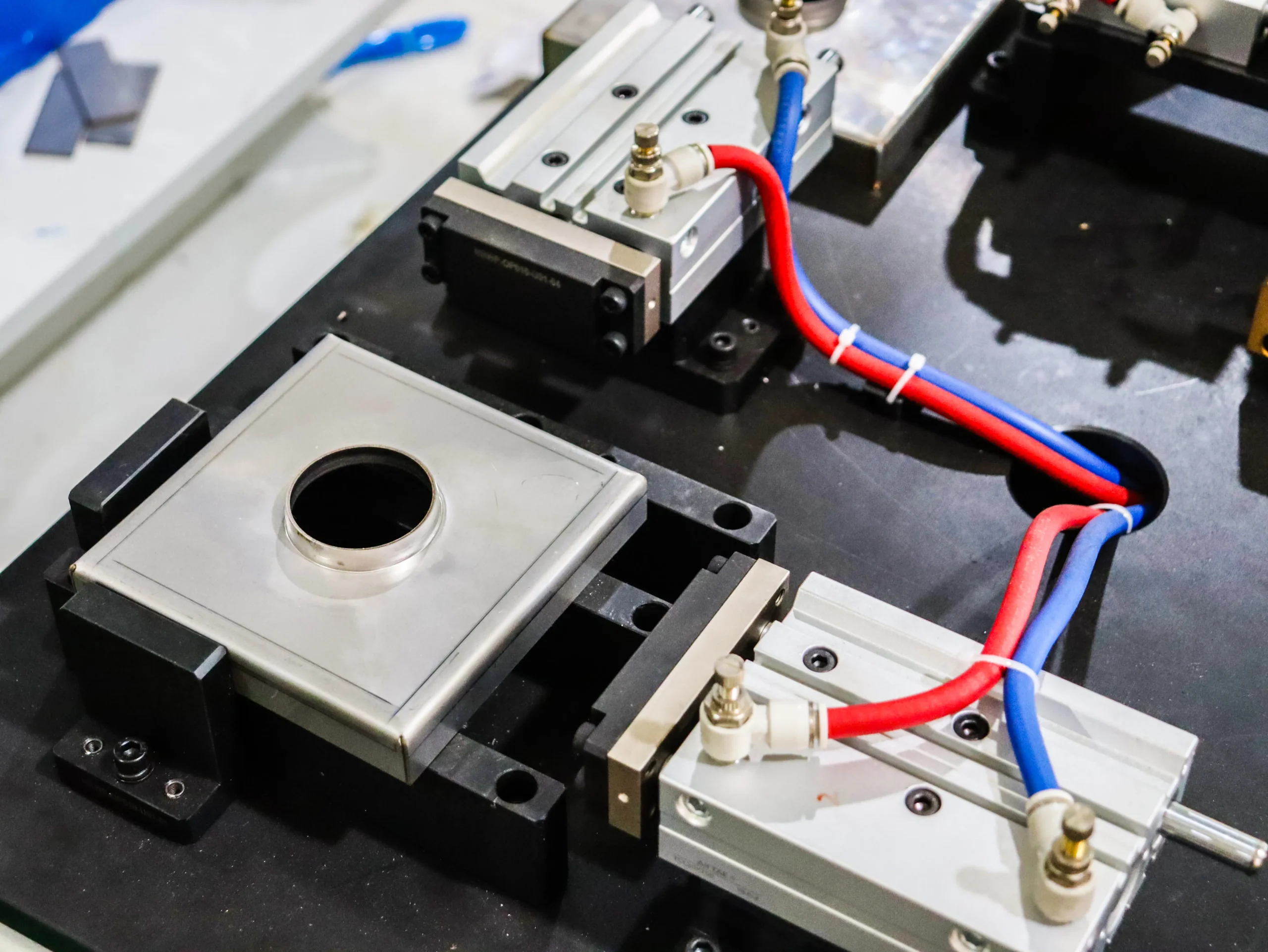

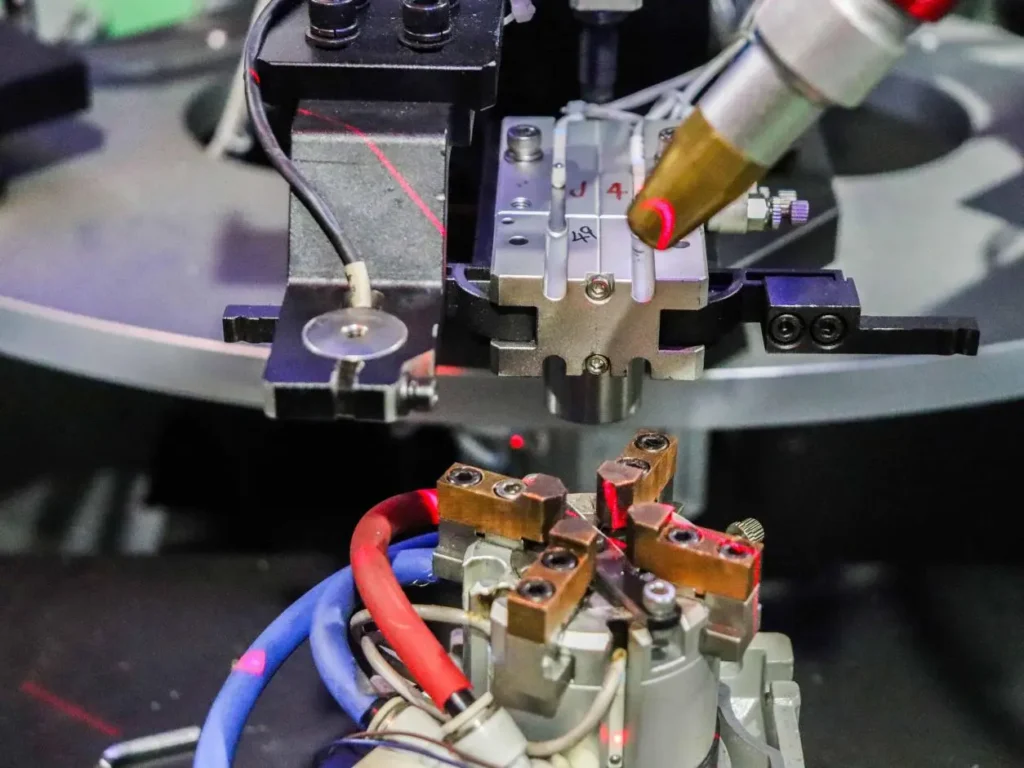

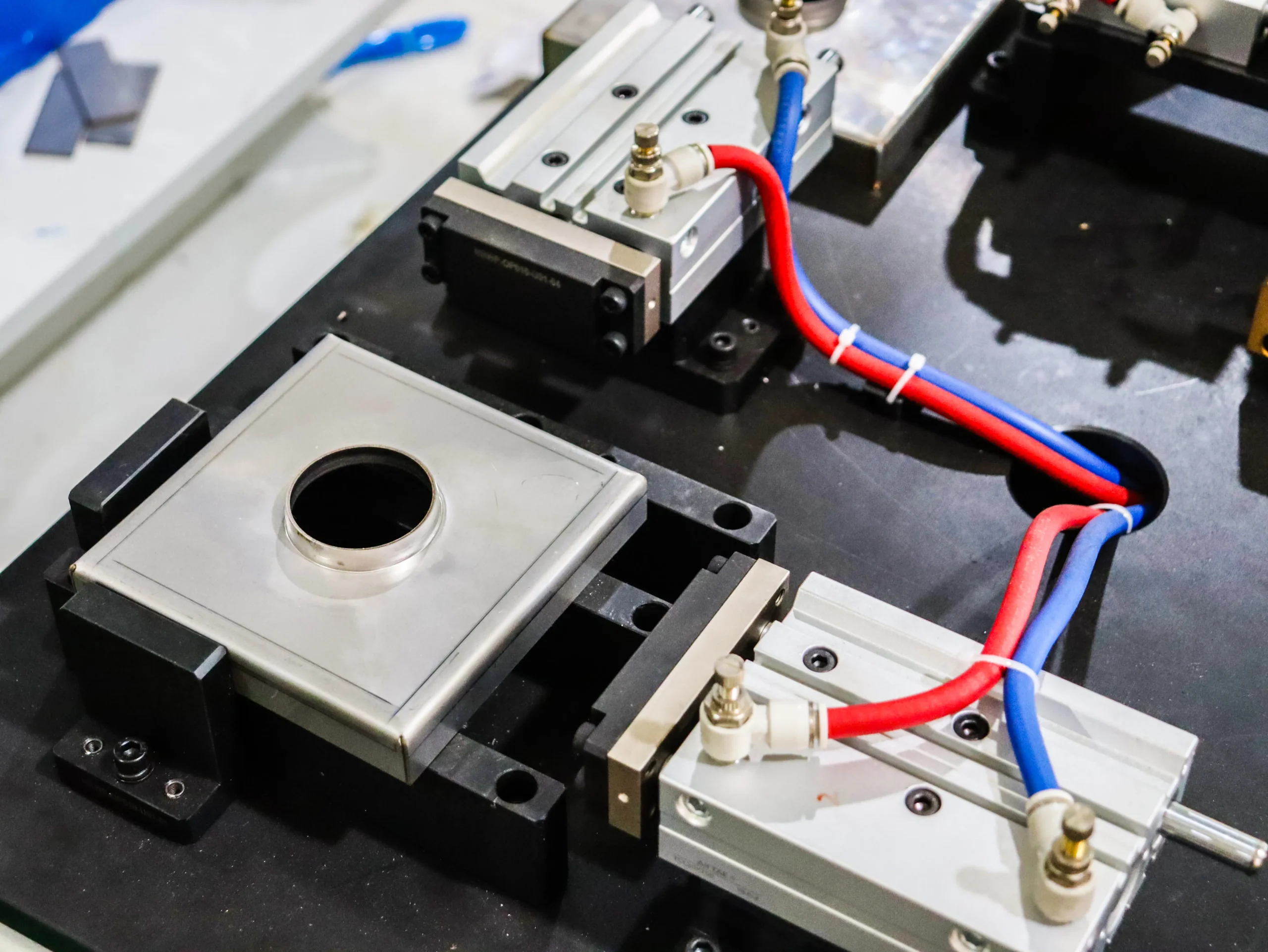

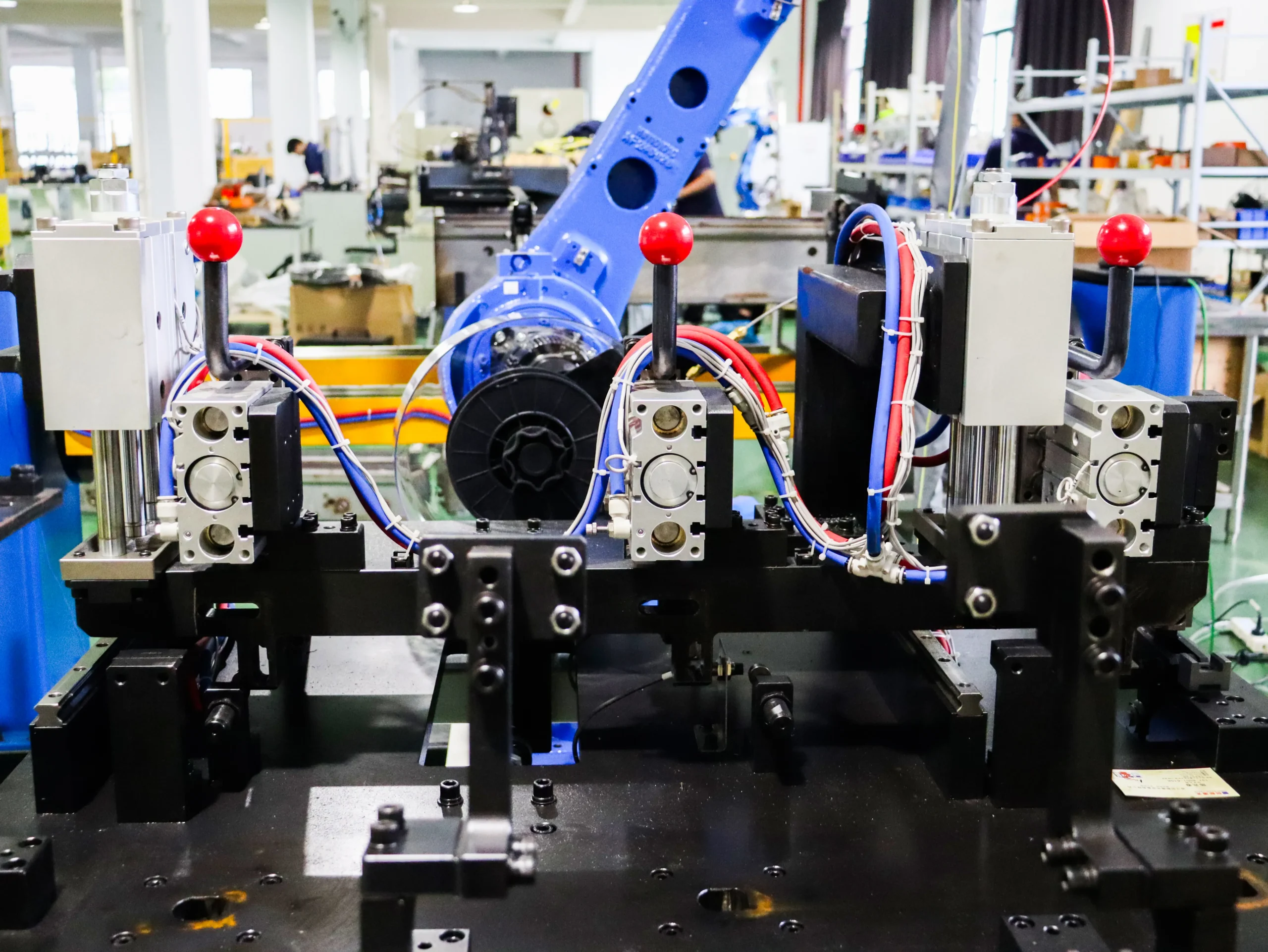

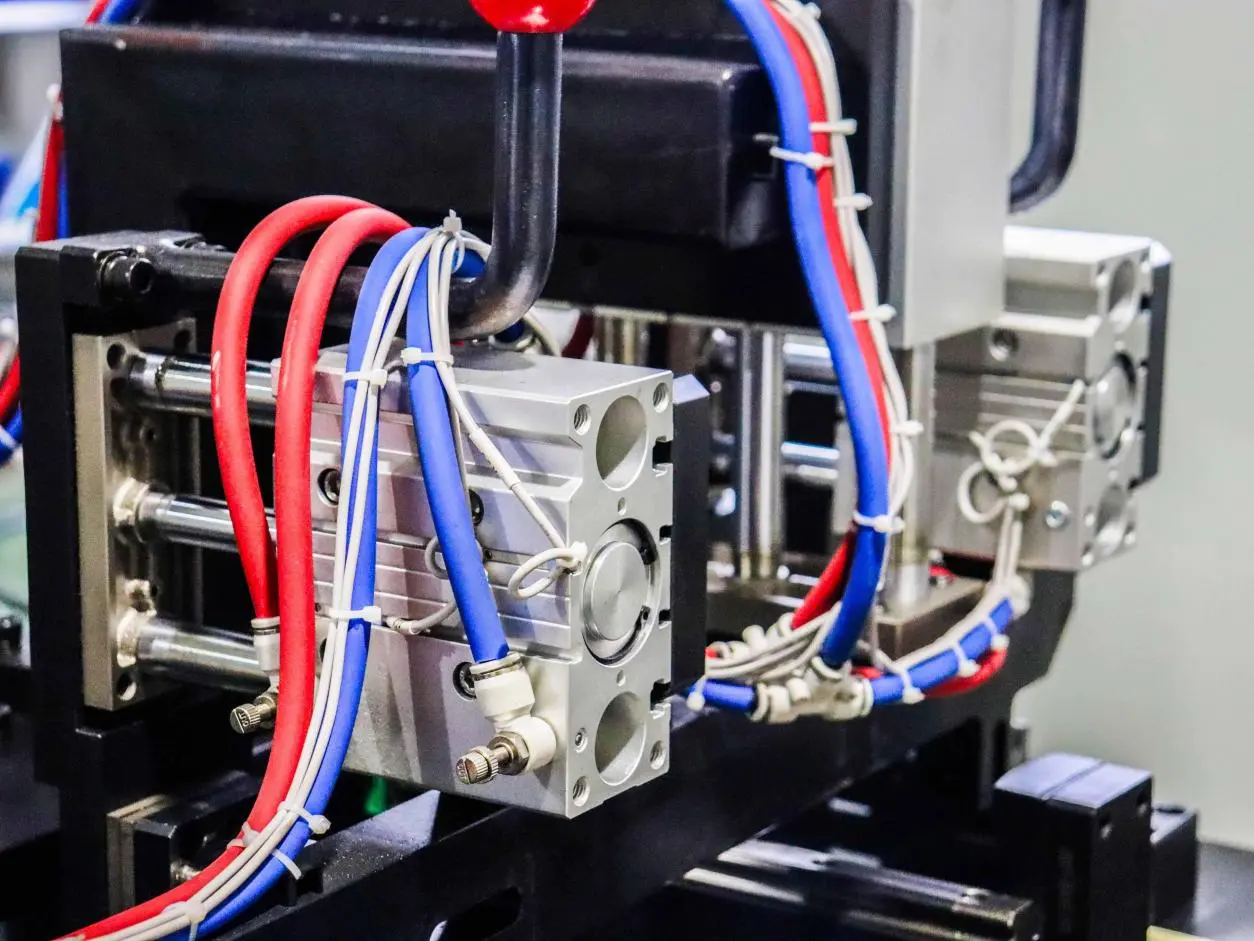

Type 2:Pneumatic/Hydraulic Actuated Fixtures

Types: Pneumatic cylinders and clamps, often controlled by the robot's PLC.

Functions: To provide automated, rapid, and consistent clamping force. This is essential for high-volume production, reducing cycle time, and enabling "Lights-Out" manufacturing. Safety interlocks ensure the robot only welds when the part is fully clamped.

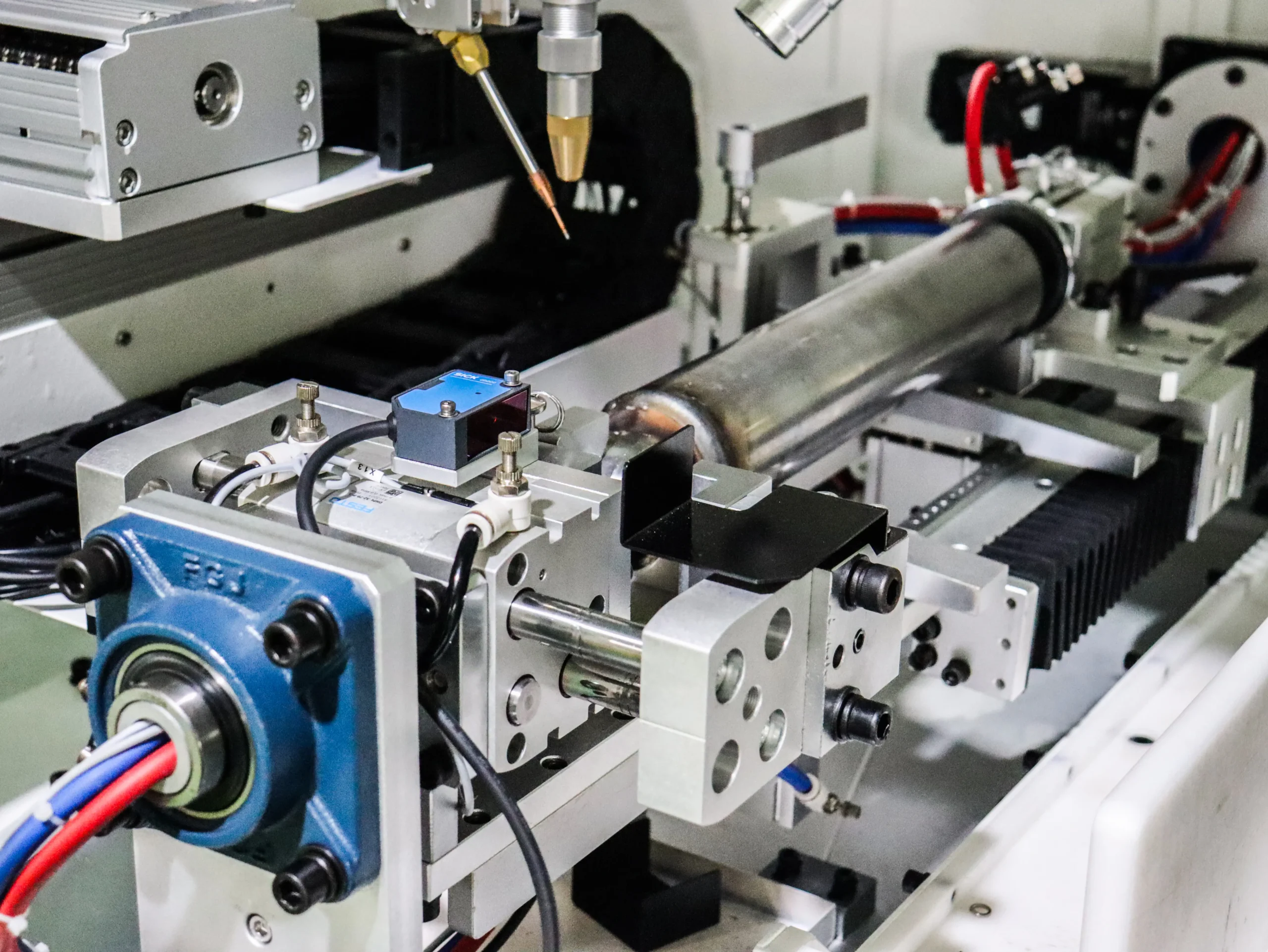

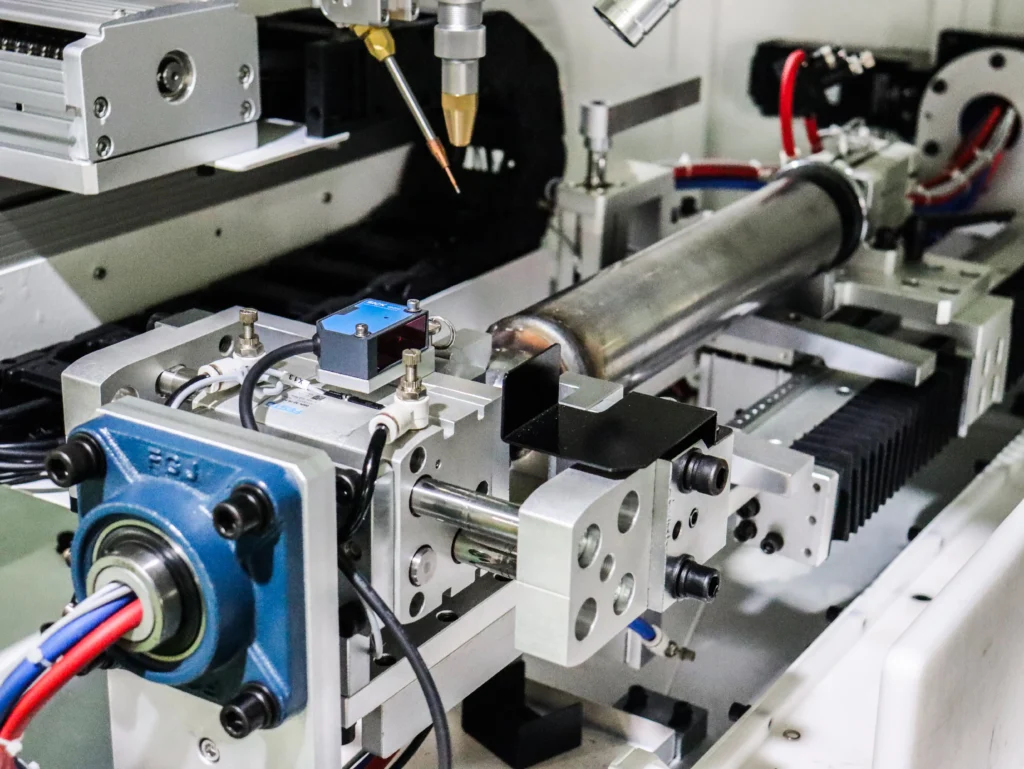

Type 3:Dedicated Fixtures

Types: Custom-built, often solid steel fixtures designed for a single, high-volume part.

Functions: To achieve maximum speed, rigidity, and precision for a specific component. They often combine multiple clamps and locators for complex assemblies.

CORE FUNCTIONS SUMMARY

Location: Precisely position the workpiece in 3D space using pins, stops, and surfaces.

Clamping: Apply force to hold the part firmly against the locators, preventing movement from thermal expansion or welding forces.

Access & Reachability: Designed to allow the robot torch access to all weld joints without collisions.

Repeatability: Ensure every part loaded into the fixture is in the exact same position, which is fundamental for robotic precision.

Safety: Integrated with the cell's safety system to prevent operation if a part is not correctly clamped.

TrueSyn Expertise:

We have the in-house expertise to handle your entire welding automation project. Our team of mechanical, electrical, and welding process engineers works in unison to deliver turnkey solutions. From design and integration to installation and support, we provide a single source for all your automation needs.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.