About Laser

- Home

- > TrueSyn Automation Production Line

A TURNKEY SOLUTION

Robotic Laser Welding Cell

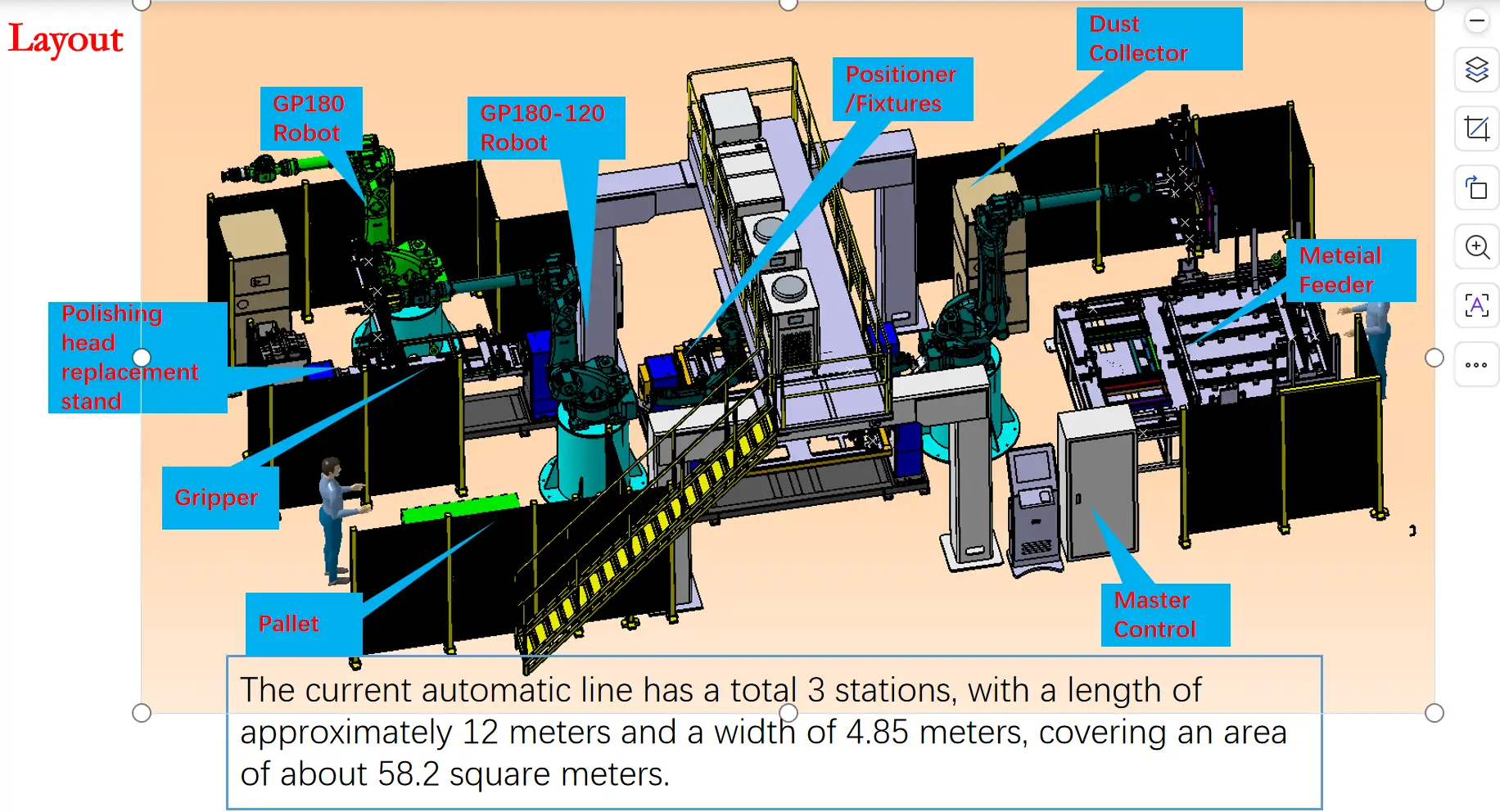

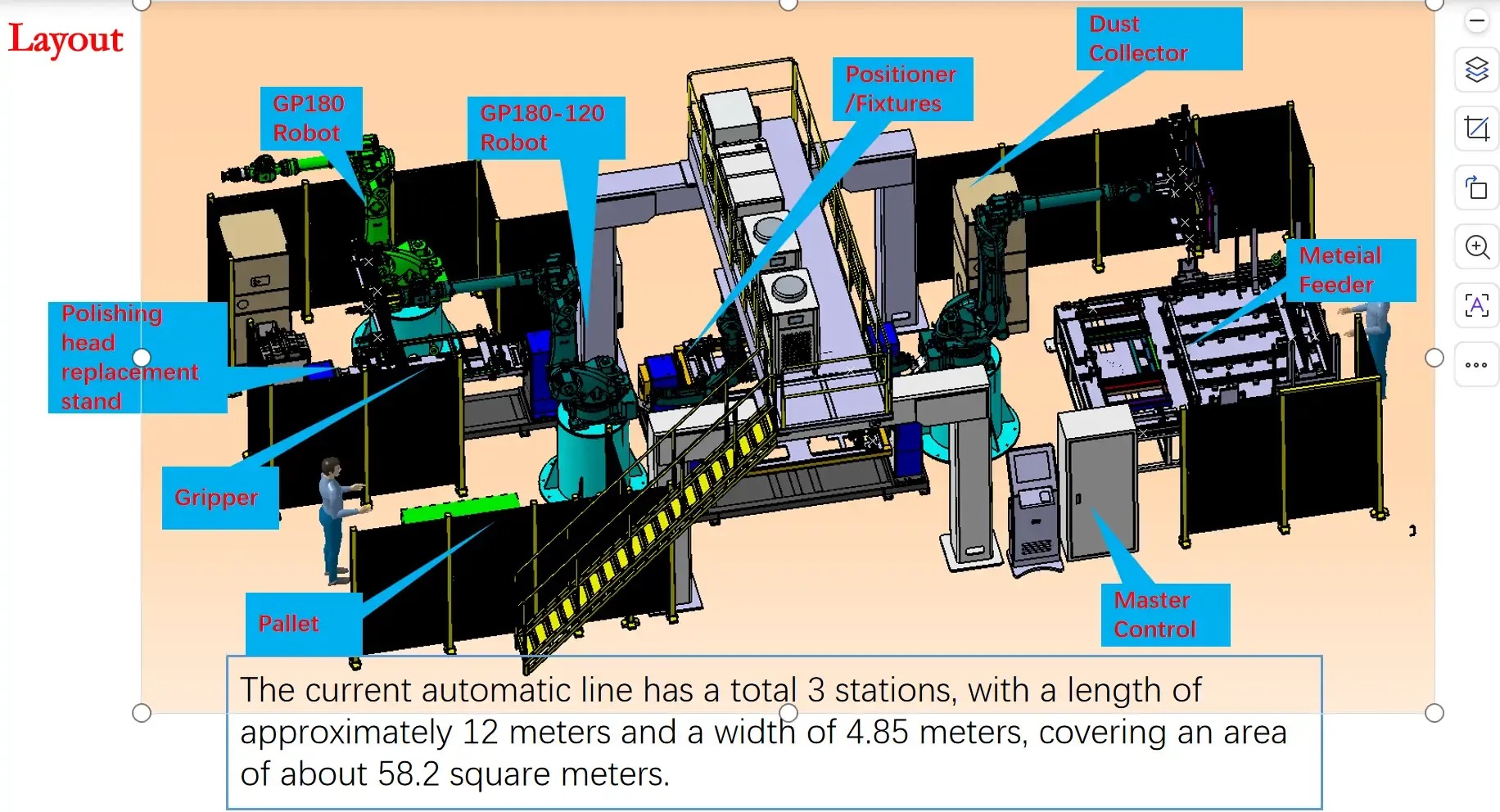

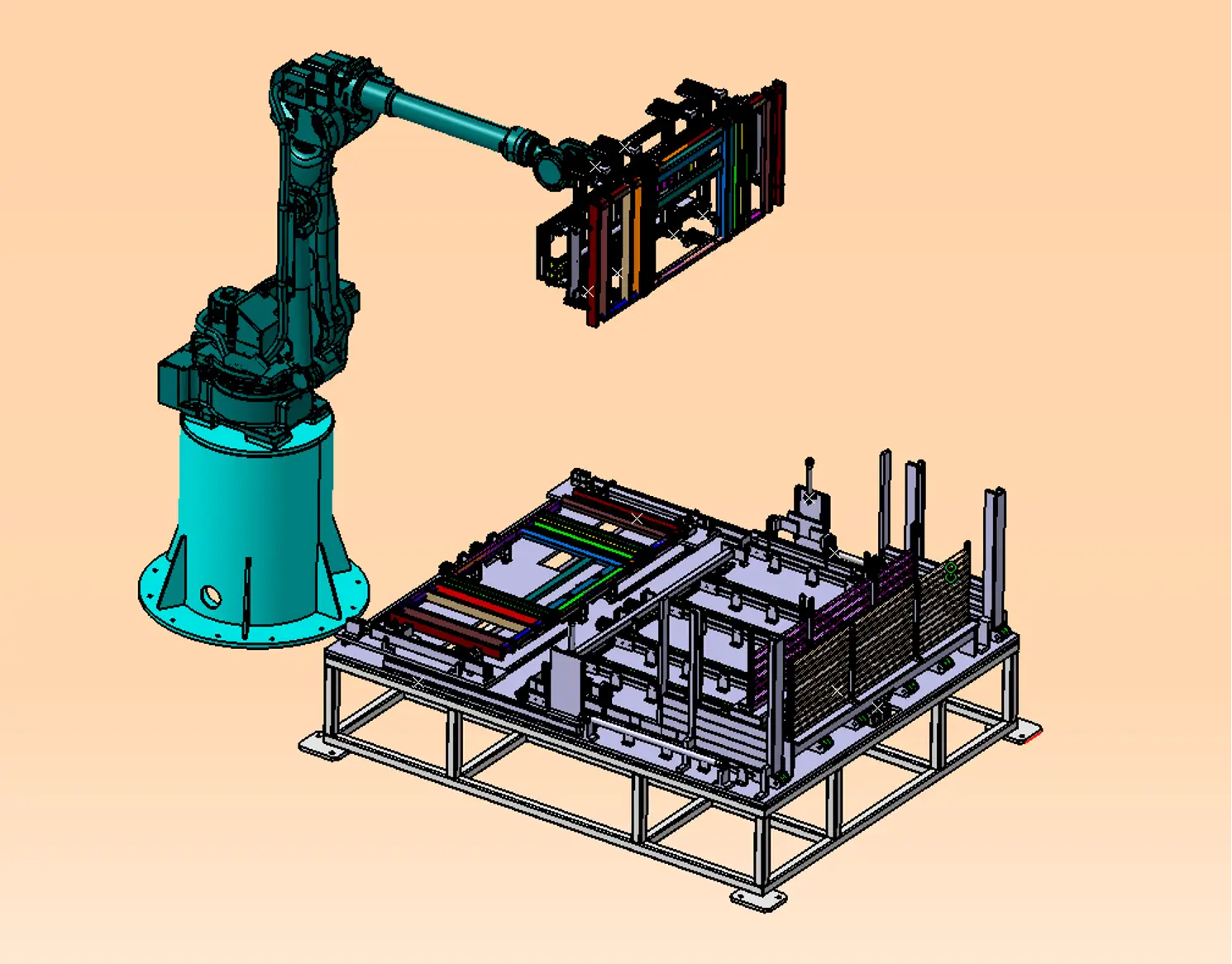

This integrated cell begins with a custom-designed loading fixture that precisely presents parts to the material handling robot. A Yaskawa Motoman GP180 robot, equipped with custom EOAT (End-of-Arm Tooling), then manages the transfer of components through the entire workflow. The core manufacturing process is performed by a high-precision Yaskawa Motoman GP25 laser welding robot, synchronized with a rotary positioner. Immediately following welding, a dedicated grinding robot, outfitted with a custom-engineered grinding head, performs finishing operations to ensure a perfect final product before unloading.

Key Features & Components

Key features and components are the essential elements that define a product’s functionality and performance. They highlight what sets a product apart and help users assess its value and suitability for their needs.

Optimized Material Presentation

Automated Material Handling

High-Precision Laser Welding

Integrated Finishing Process

Dual-Station Rotary Positioner

Seamless Integration

Our Integrated Engineering Capability

The synergy of our specialized teams is the foundation of our success. Our mechanical design team creates robust fixtures and tooling/fixtures; Our electrical engineering team ensures flawless system integration and control; and our welding technique team optimizes every parameter for welding quality and efficiency. This collaborative structure is how we transform a concept into a fully validated, production-ready solution.

Our Evolution: From Specialists to Integrators

While our foundation is built on expert laser welding, we have successfully evolved from a single welding equipment supplier into a comprehensive automation solutions partner. By leveraging our full in-house engineering talent, we offer end-to-end, turnkey solutions that integrate multiple manufacturing processes, tackling our clients’ broader production challenges and delivering not just equipment, but guaranteed performance and results.