About Laser

- Home

- > MIG Welding Cobot

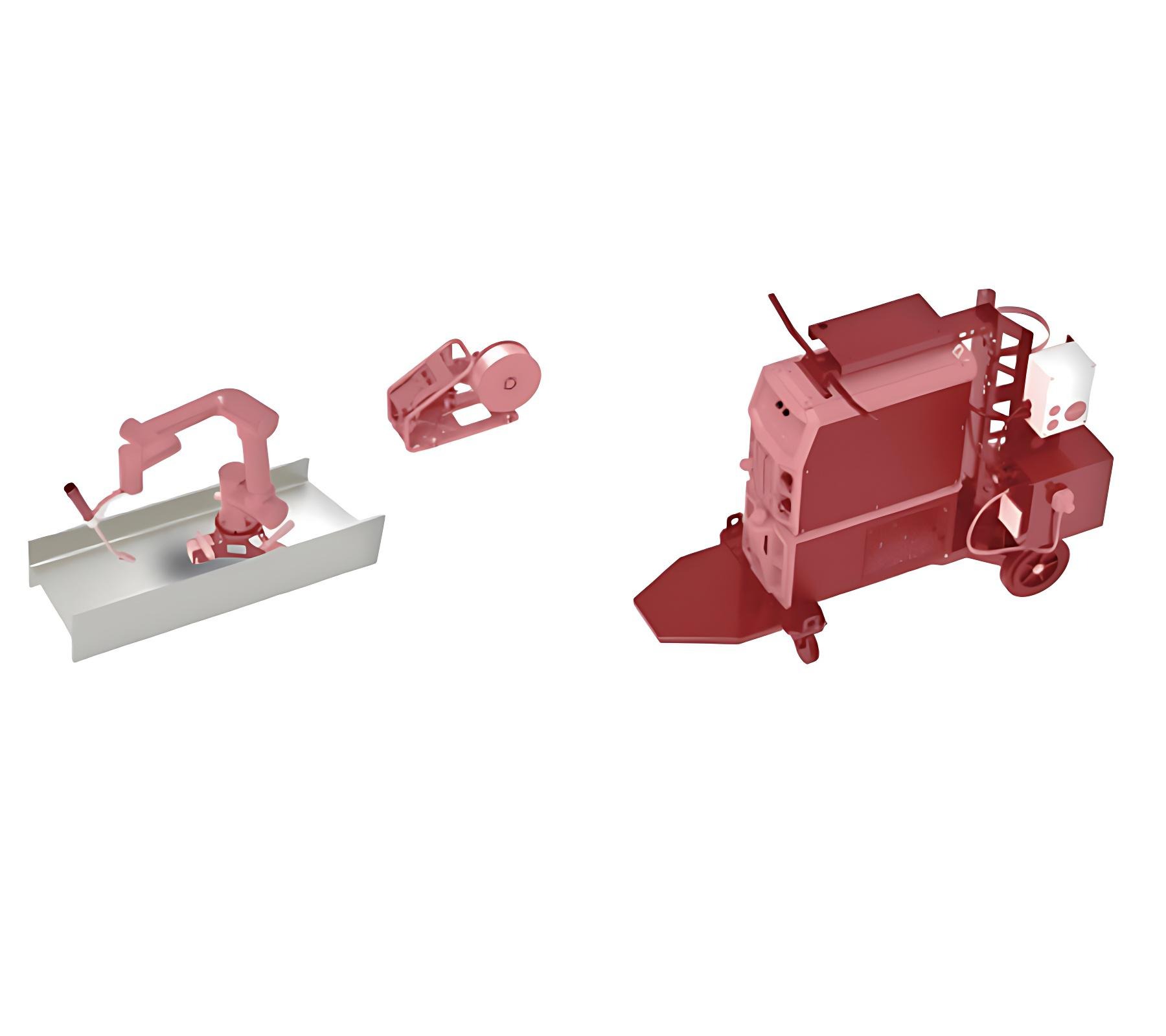

MIG Welding Cobot

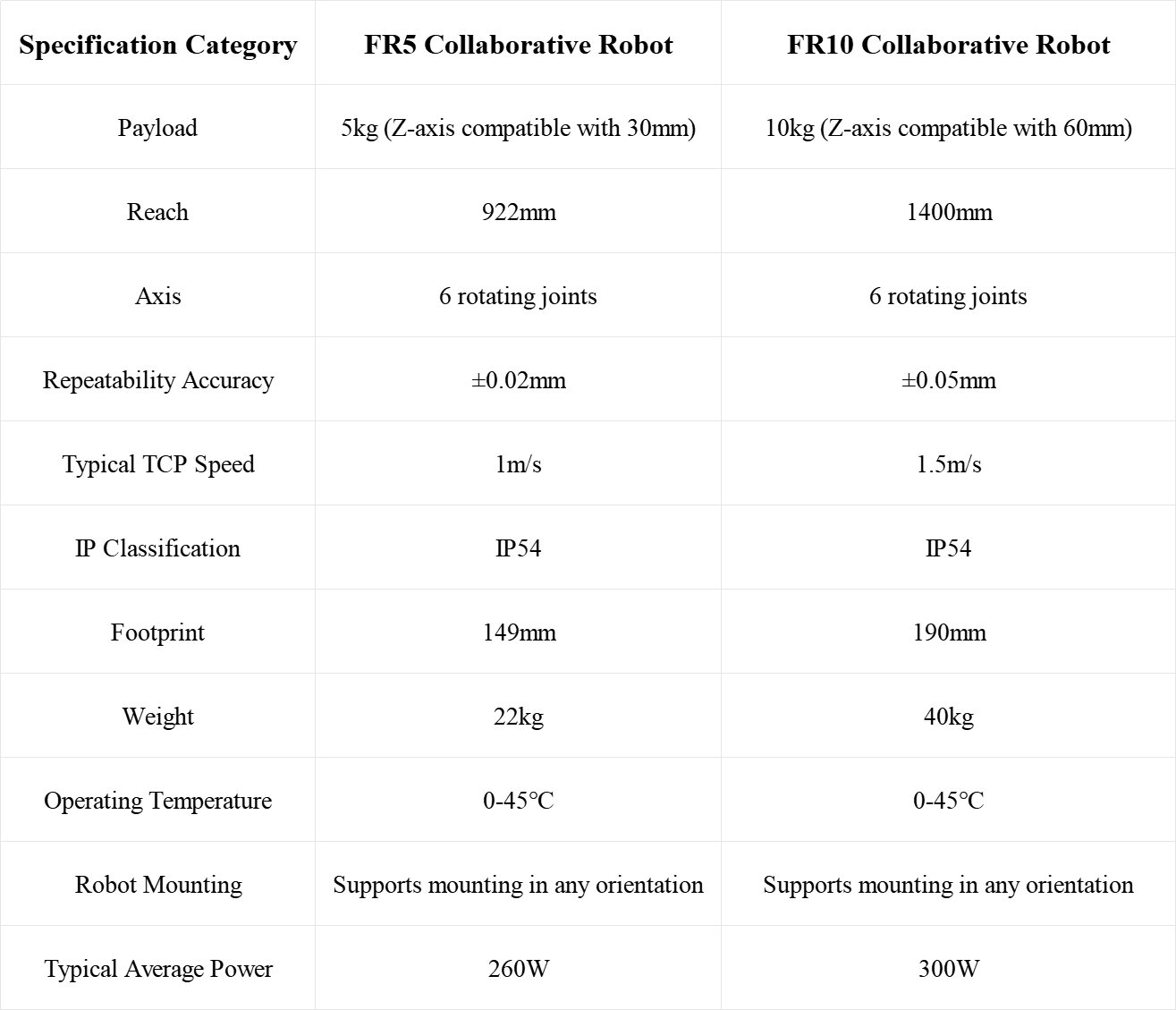

- FR5: Lightweight with 5kg payload, 922mm reach and ±0.02mm precision—ideal for high-accuracy small-part welding.

- FR10: Medium-payload (10kg) with 1400mm long reach—perfect for medium-large workpieces.

| Specification Category | FR5 Collaborative Robot | FR10 Collaborative Robot |

| Payload | 5kg (Z-axis compatible with 30mm) | 10kg (Z-axis compatible with 60mm) |

| Reach | 922mm | 1400mm |

| Axis | 6 rotating joints | 6 rotating joints |

| Repeatability Accuracy | ±0.02mm | ±0.05mm |

| Typical TCP Speed | 1m/s | 1.5m/s |

| IP Classification | IP54 | IP54 |

| Footprint | 149mm | 190mm |

| Weight | 22kg | 40kg |

| Operating Temperature | 0-45℃ | 0-45℃ |

| Robot Mounting | Supports mounting in any orientation | Supports mounting in any orientation |

| Typical Average Power | 260W | 300W |

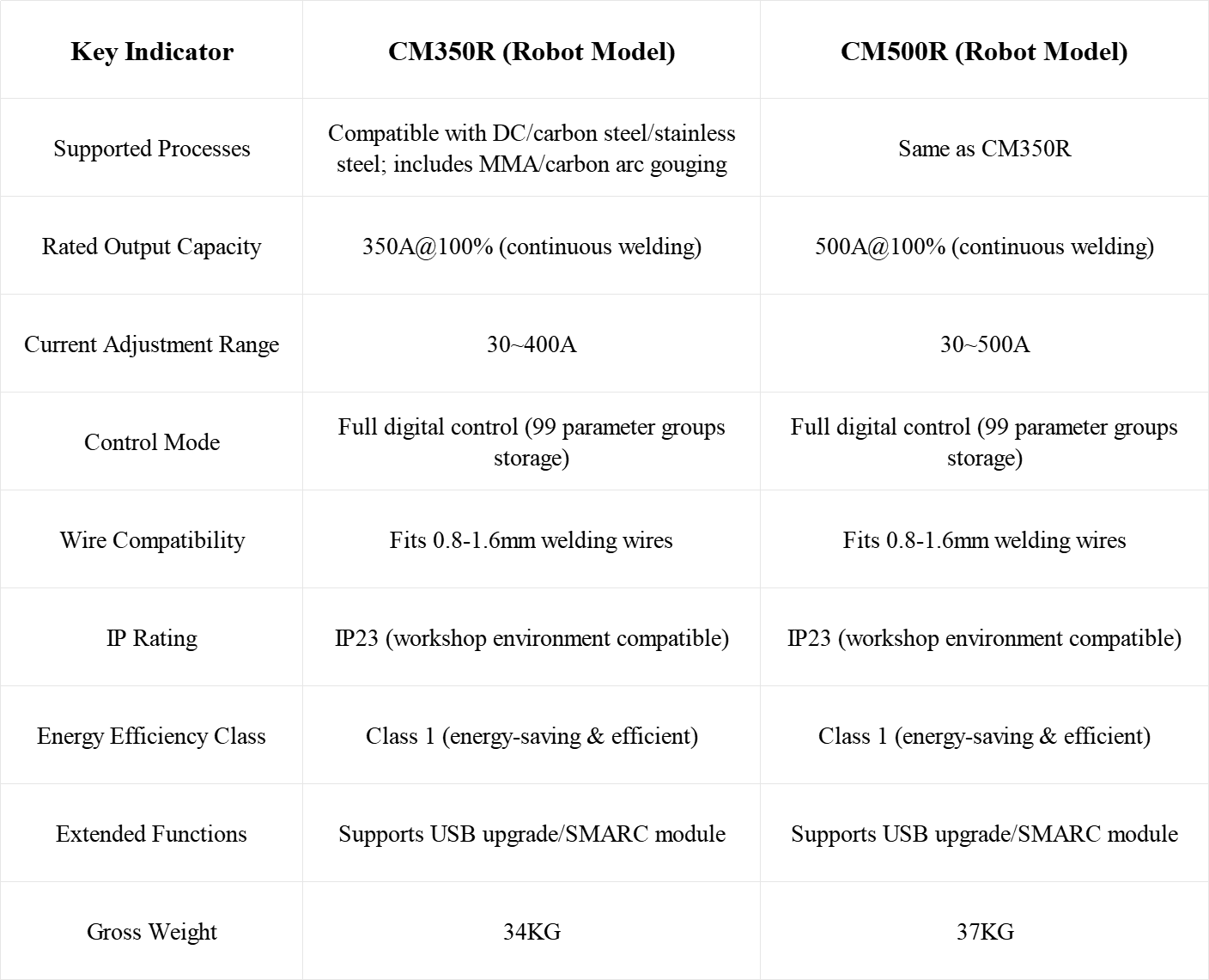

| Key Indicator | CM350R (Robot Model) | CM500R (Robot Model) |

| Supported Processes | Compatible with DC/carbon steel/stainless steel; includes MMA/carbon arc gouging | Same as CM350R |

| Rated Output Capacity | 350A@100% (continuous welding) | 500A@100% (continuous welding) |

| Current Adjustment Range | 30~400A | 30~500A |

| Control Mode | Full digital control (99 parameter groups storage) | Full digital control (99 parameter groups storage) |

| Wire Compatibility | Fits 0.8-1.6mm welding wires | Fits 0.8-1.6mm welding wires |

| IP Rating | IP23 (workshop environment compatible) | IP23 (workshop environment compatible) |

| Energy Efficiency Class | Class 1 (energy-saving & efficient) | Class 1 (energy-saving & efficient) |

| Extended Functions | Supports USB upgrade/SMARC module | Supports USB upgrade/SMARC module |

| Gross Weight | 34KG | 37KG |

As a core accessory of Innovation Laser’s welding system, it can carry FR5/FR10 robots and CM350R/500R welders, integrating key modules. The strong magnetic base fixes in 3 seconds to prevent displacement. With 9-step standardized

Operation Procedure: 1.Input power supply, connect the gas bottle, and install the welding wire according to the technical parameters; 2. Pull the welding trolley to the desired location and lock the brakes; 3.Move the cobot to the working area and close the magnetic switch to fix the cobot; 4.Tunr on the electical power and wait for the power indication light on; 5.Using tha programming tablet to choose the technique template or setting the parameters 6.Using the SmrtTool to locate the welding point and program; 7. After first time programming, please run the cobot to test the trajectory; 8.After testing the trajectory, then start the welding 9.Replace the workpiece once welding is done

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.