About Laser

- Home

- > Yaskawa Laser Cutting Robot-2kw/3kw

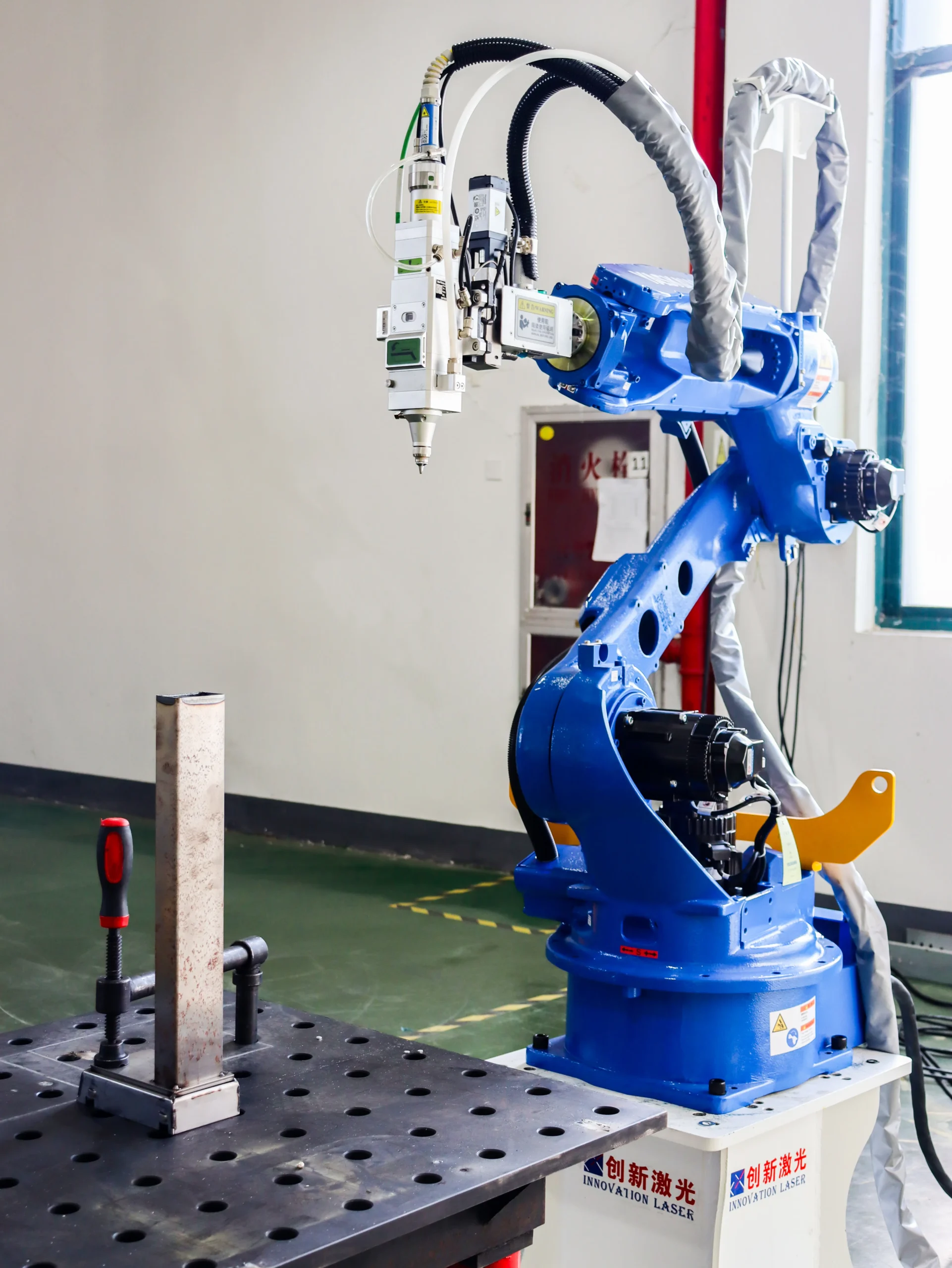

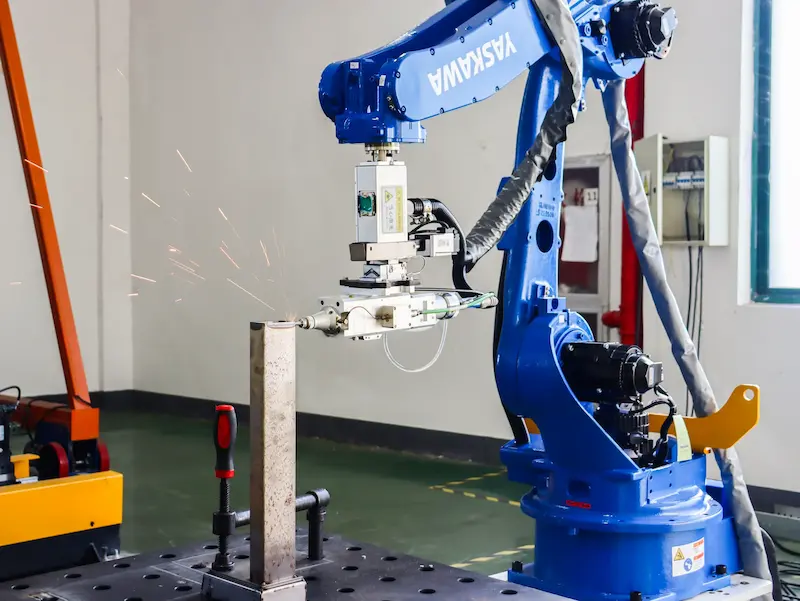

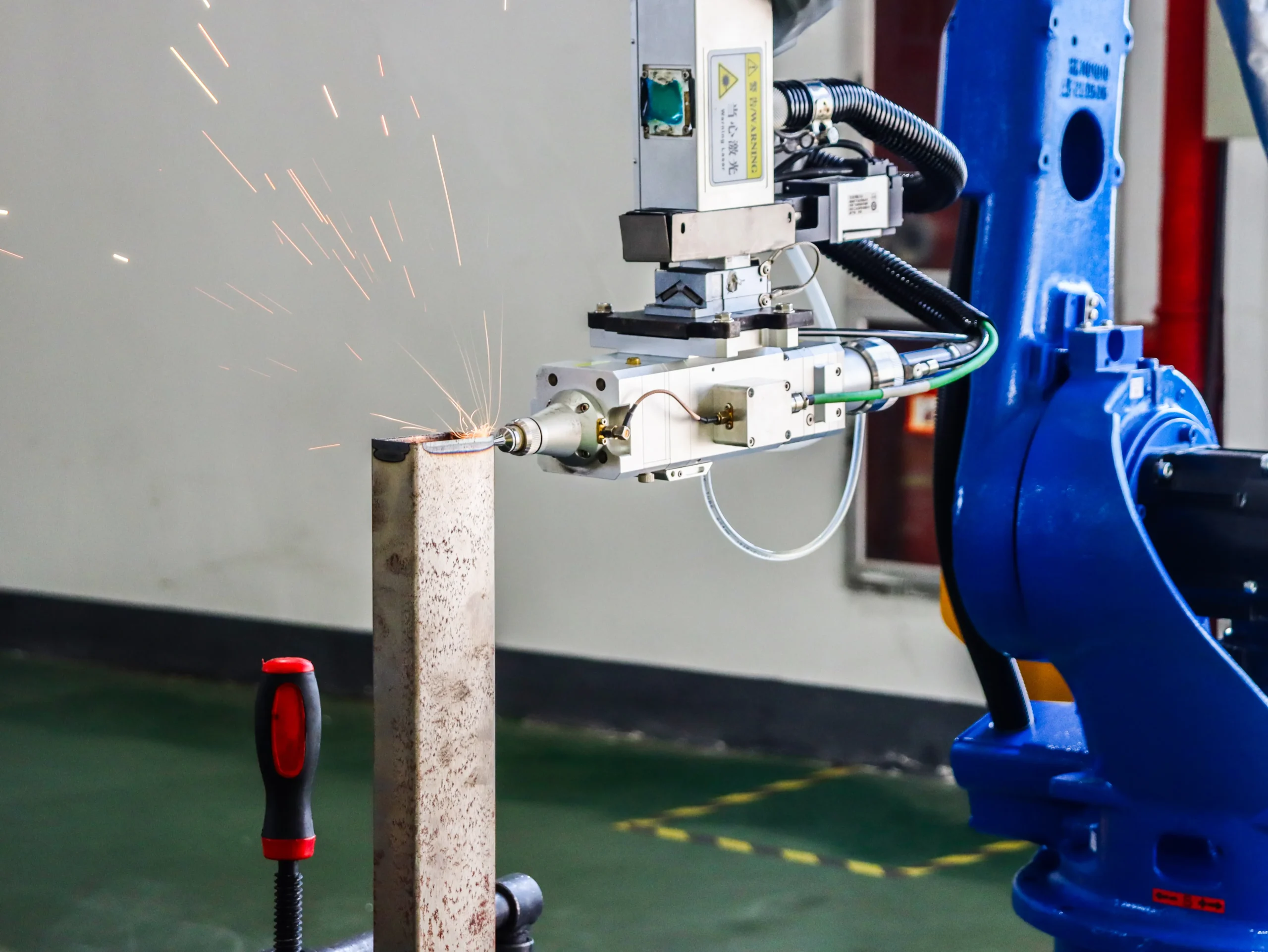

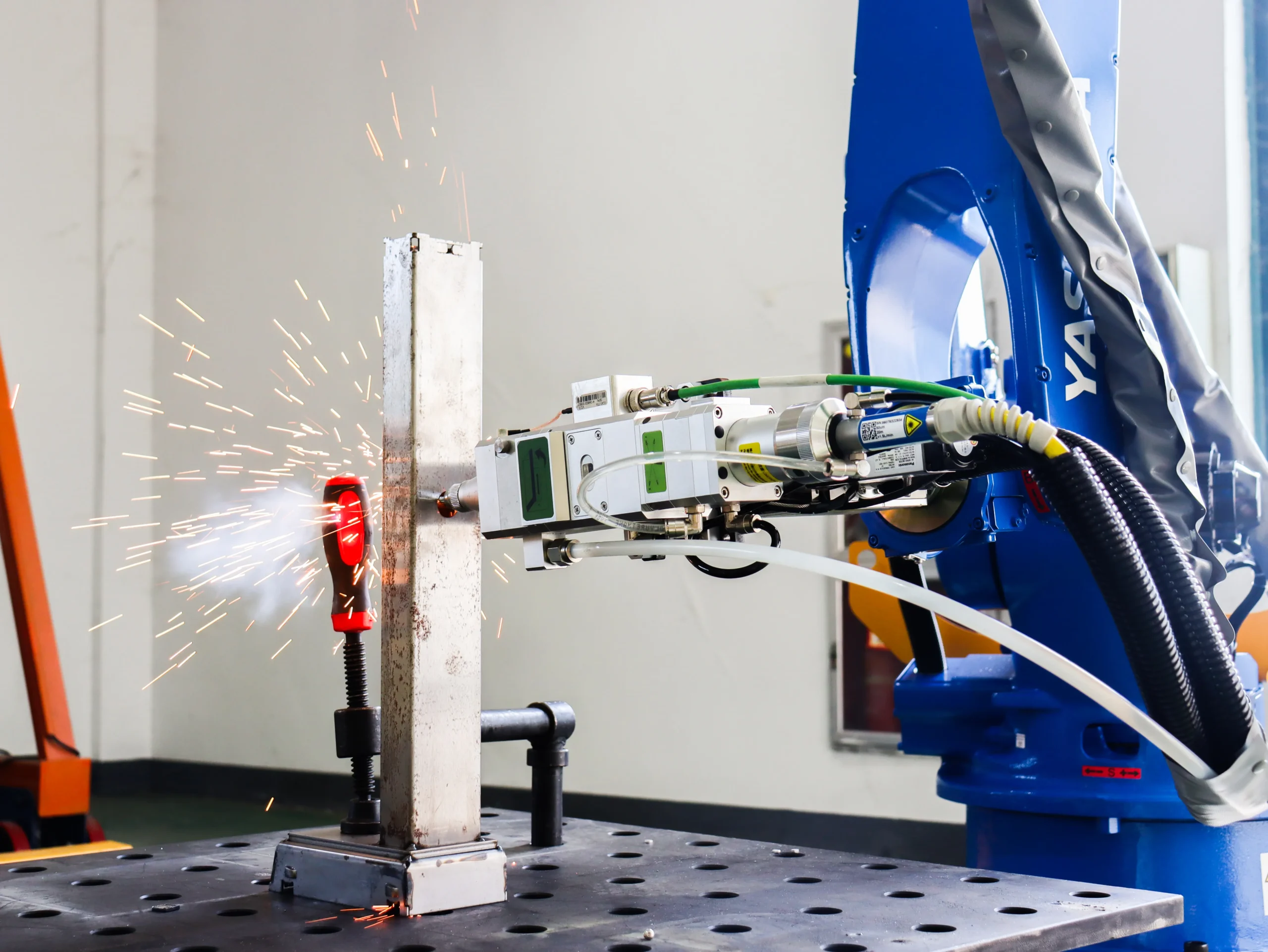

Yaskawa Cutting Robots

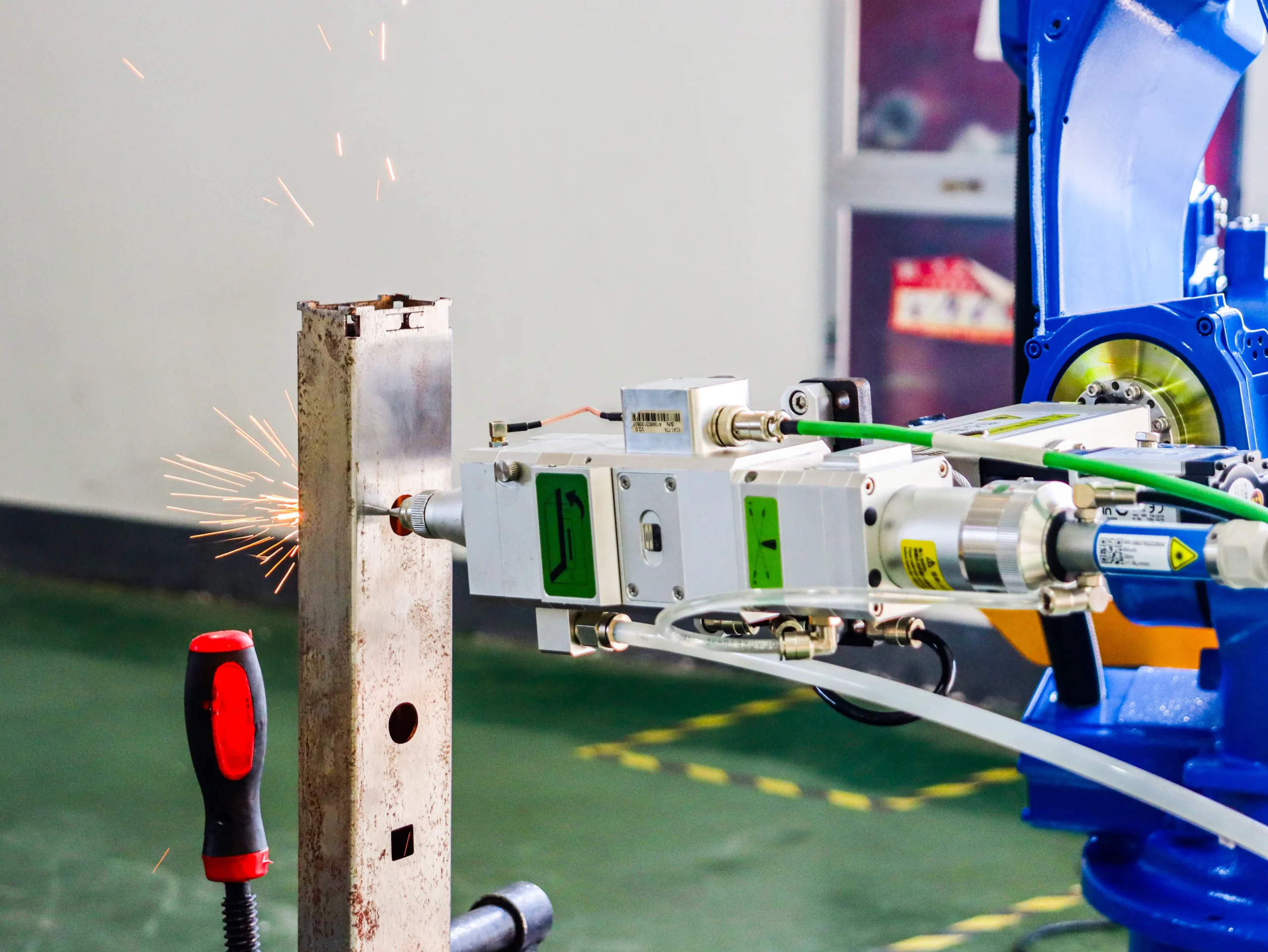

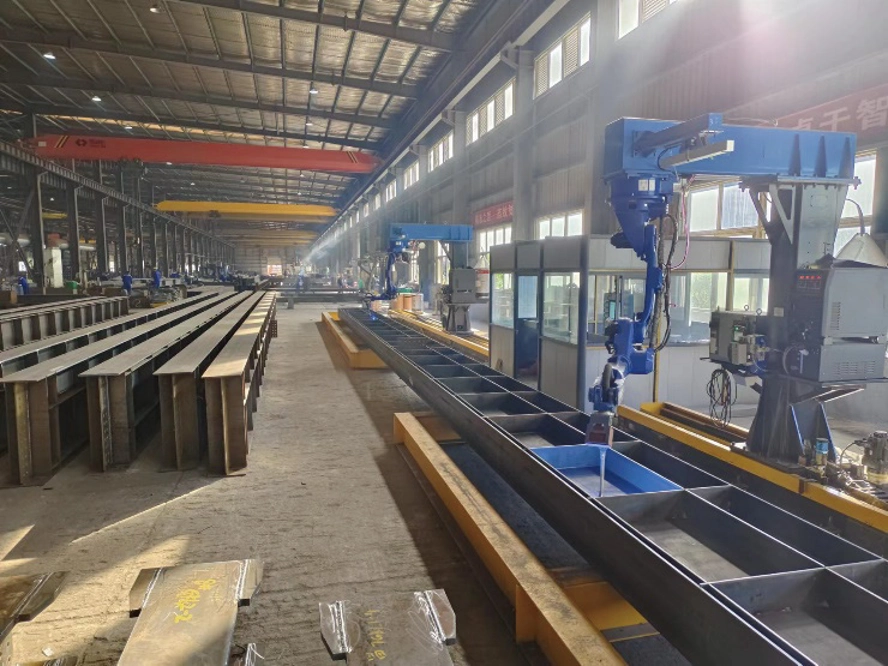

Yaskawa cutting robots are renowned for their exceptional motion flexibility and stability. They excel in complex 3D path processing, such as automotive metal sheets or special-shaped tubes. This highly integrated solution effectively boosts productivity and processing quality, making it a reliable and efficient top choice for demanding 3D cutting applications.

Product Description

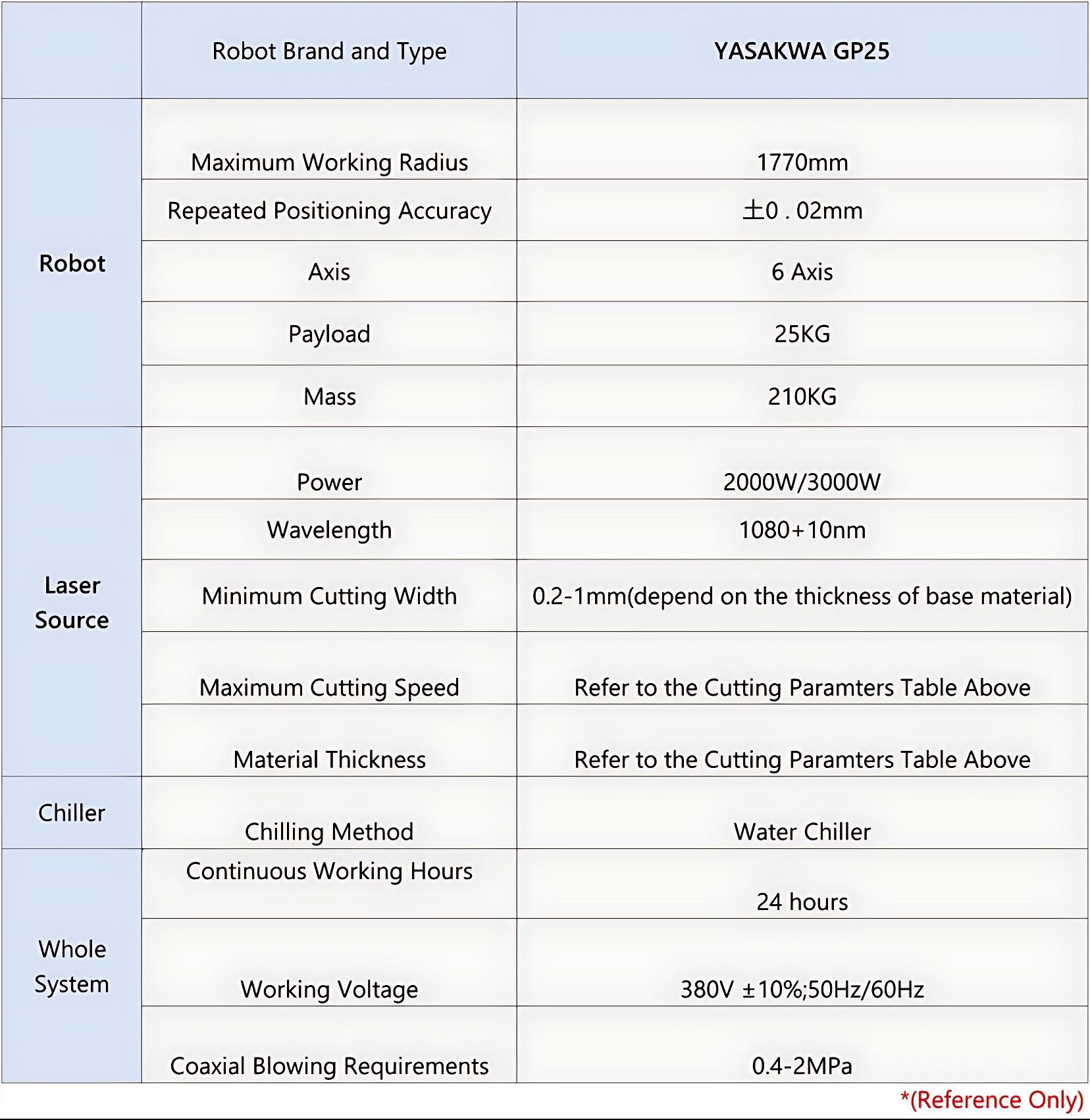

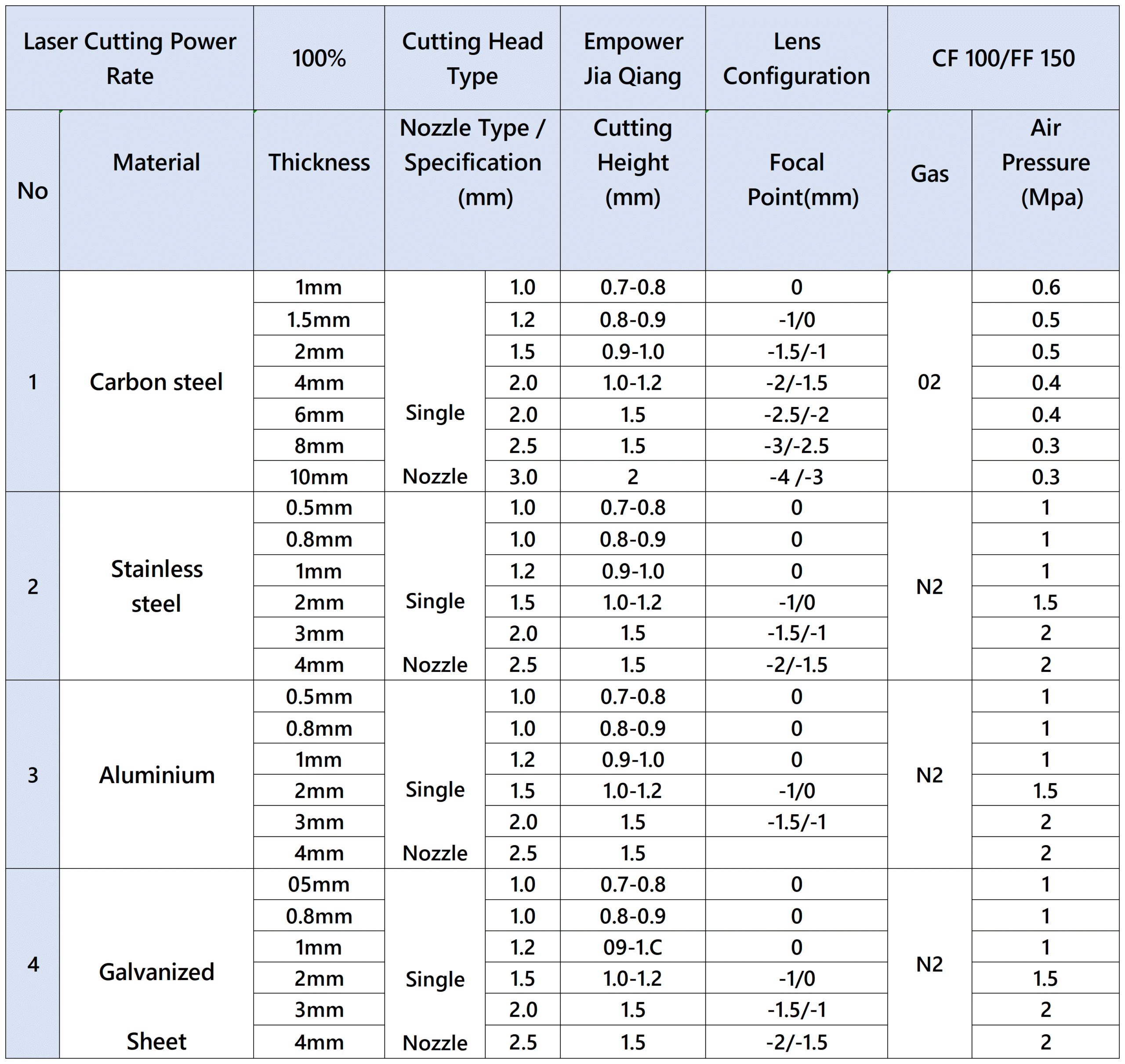

Customizable configs: Laser source options (2000W/3000W), paired with top-tier components (Raycus/MAX/Trumpf/IPG lasers)

Strong performance: Cuts up to 10mm thick materials; 3D cutting with auto height following & collision avoidance for precision.

Safe & reliable: Safe enclosures block laser radiation; robust robots support 24/7 use with low maintenance.

Efficient production: Offline programming for small-batch efficiency; high-speed 6-axis robot movement.

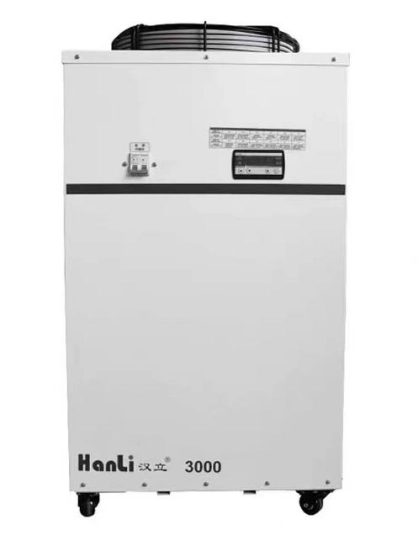

Stable integration: Partners with FANUC/Yaskawa/ABB; matched with HanLi high-performance water chiller.

- Power Demand: 380VAC,50/60 Hz(or adjust as per actual cutting equipment requirements)