About Laser

- Home

- > Water Cooling Handheld Fiber Laser Welding Machine

Water Cooling Handheld Fiber Laser Welding Machine

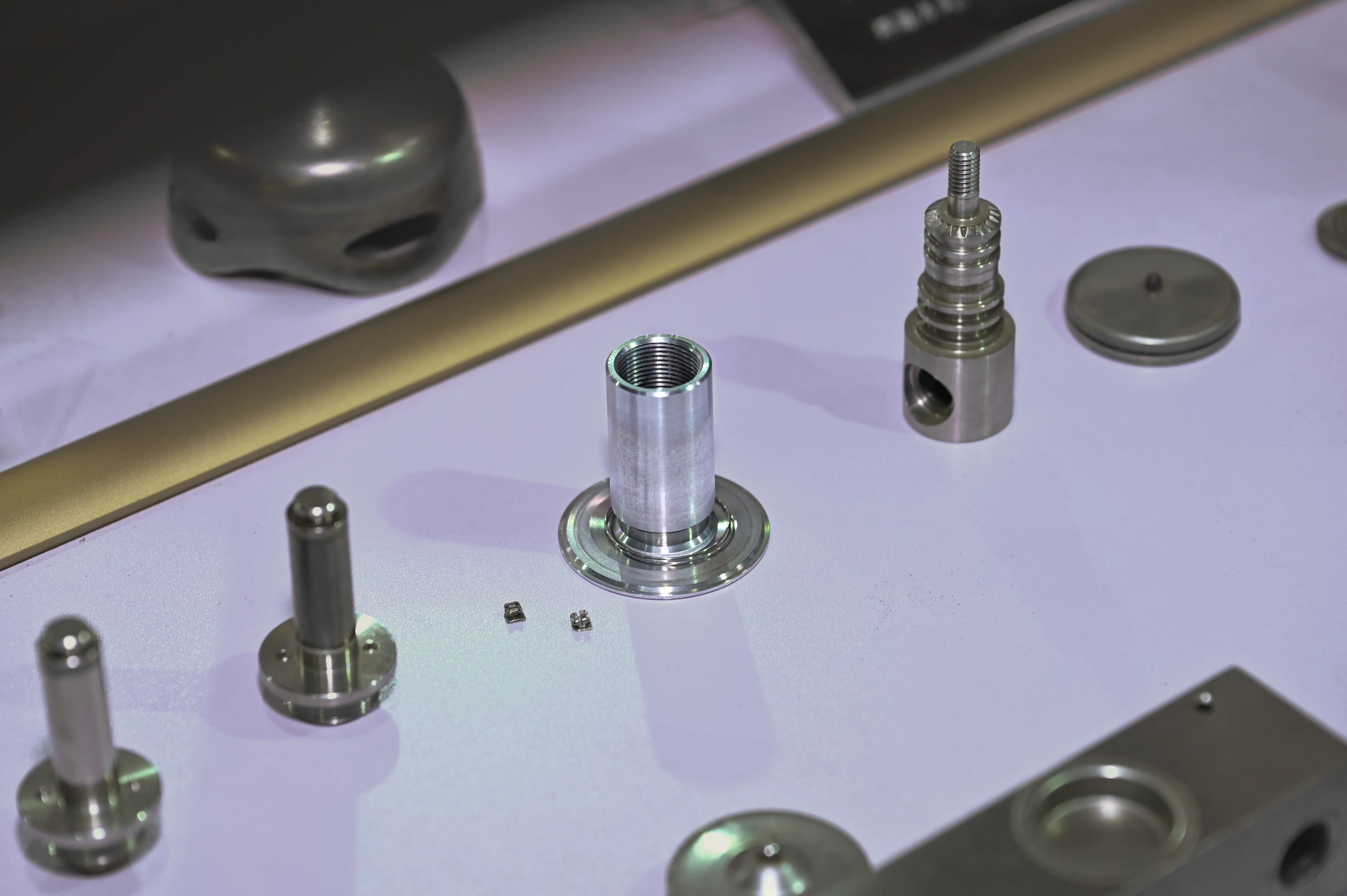

Water-cooled handheld fiber laser welder: portable, flexible 360° welding for irregular/large workpieces.

Boasts stable water cooling, multi-power options, fast speed, precise positioning, and small heat-affected zone.

Compatible with various metals, supports optional wire feeders. Widely used in sheet metal, hardware, auto parts industries.

Innovationlaser@zjcxlaser.com

01

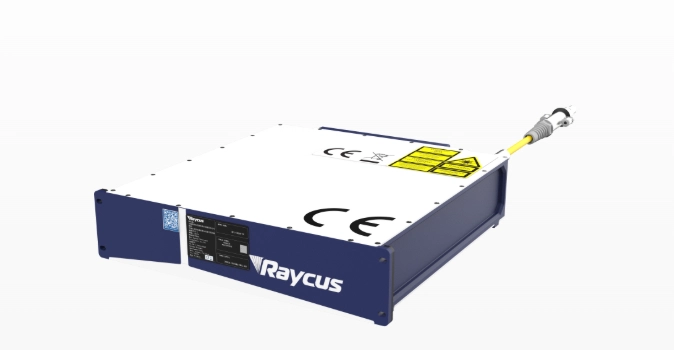

Laser Source

The laser is the core, defining the process and its capabilities. To ensure optimal performance for every application, we leverage top-tier lasers from Raycus, MAX, Trumpf, and IPG, selecting the ideal technology to meet our clients' precise requirements.

02

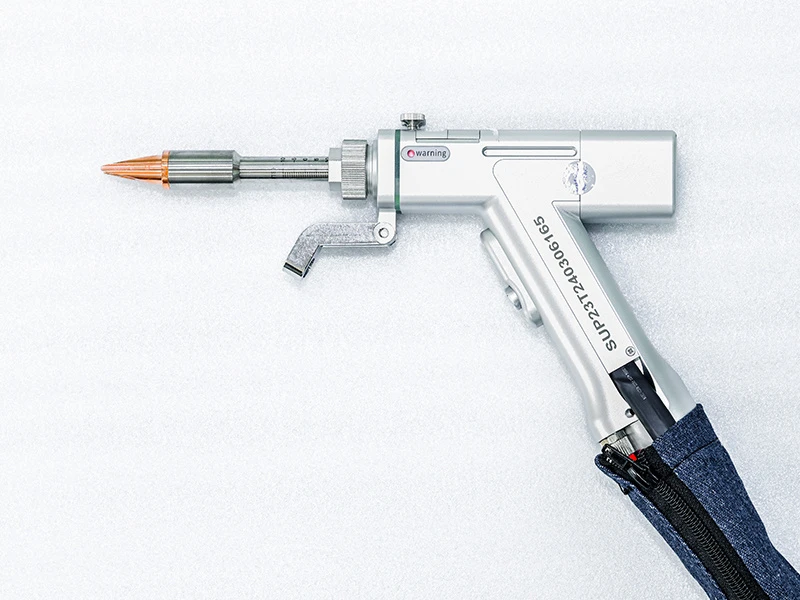

Automatic Wire Feeding System

The optional automatic wire feeder fits handheld laser welders. It feeds wire stably and precisely with adjustable speed, boosting weld quality and strength. Compatible with various wires and materials, it’s easy to use and expands welding applications.

03

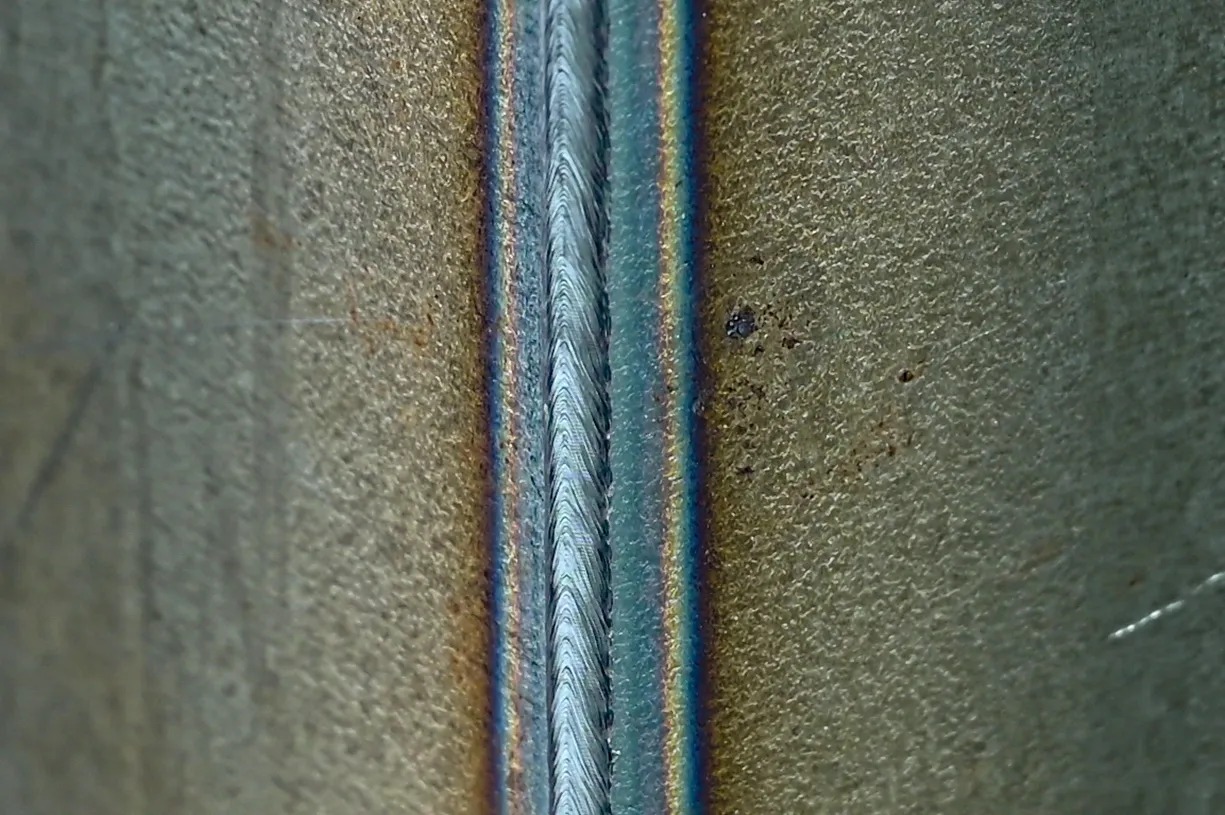

Wobble Welding Head

Our self-developed WOBBLE welding head is a core component of the machine, featuring adjustable spot width and strong welding fault tolerance. It enables flexible operation for complex welding tasks and is compatible with the optional automatic wire feeding system.

04

Water chiller

Our Chiller is a high-performance cooling solution designed for various industrial and commercial applications.

Advantages

Product Description

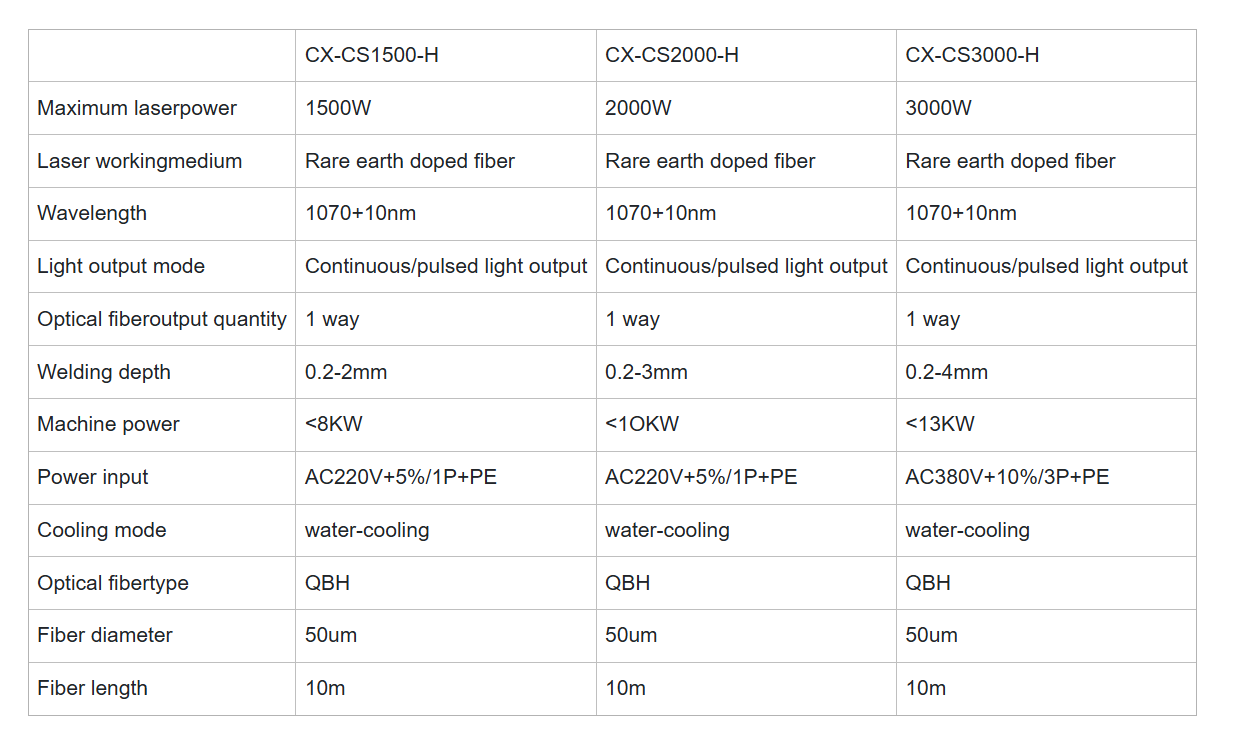

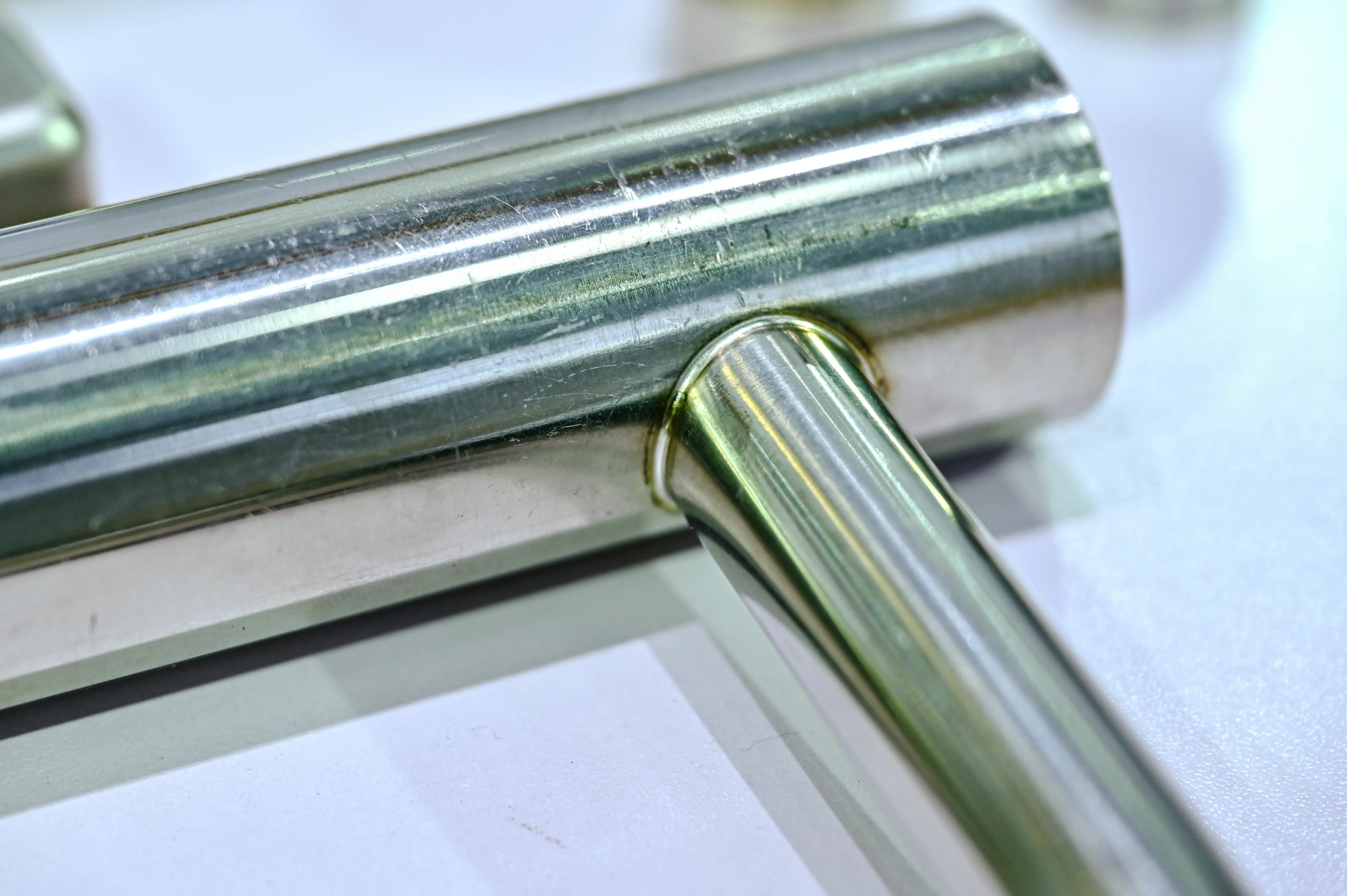

Our water-cooled handheld fiber laser welding machine on the site offers 1500W/2000W/3000W power options. It features a self-developed WOBBLE welding head (adjustable spot width, strong fault tolerance) and a water cooling system for stable long-hour operation. With a 10m QBH optical fiber, it enables flexible 360° welding on complex/irregular workpieces. Optional automatic wire feeder enhances weld quality. Suitable for metal materials like stainless steel, it’s widely used in sheet metal, kitchenware, and construction industries.

- Power Demand: 220/380VAC,50/60 Hz

01

Automobile Industry

Laser welding enables high-precision, high-speed automotive manufacturing with minimal distortion, supports diverse materials, and enhances strength, durability, and aesthetics through automation.

02

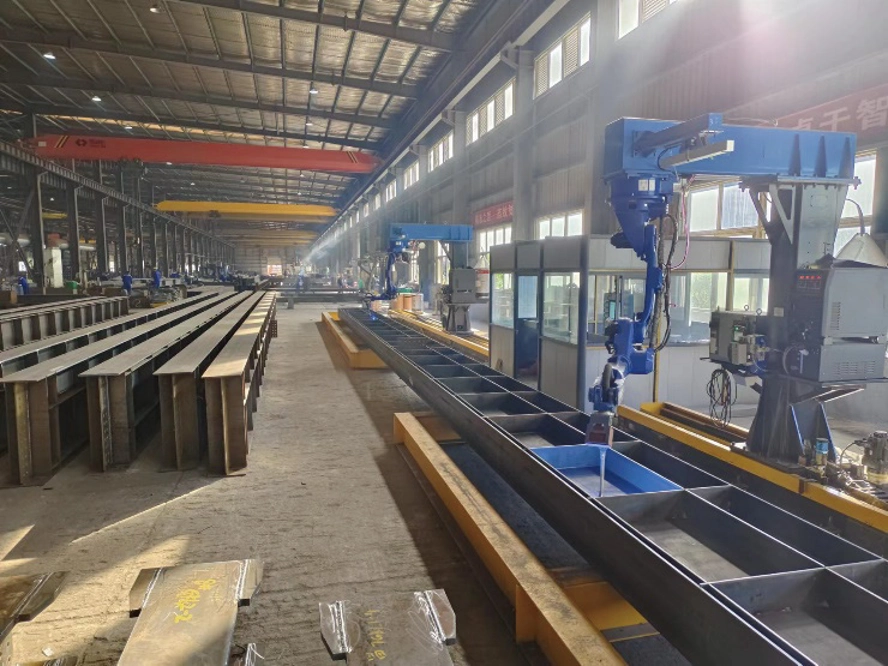

Construction & Steel industry

Programming-free arc welding robots in steel structures use vision and AI for adaptive welding. They auto-identify seams, plan paths, reduce manual work, handle tolerances, and boost quality and efficiency for flexible, small-batch production.

03

Electric Power industry

Laser welding robots for GIS/RMU ensure airtight seams with high precision, minimal distortion, and consistent strength, enhancing safety and reliability through automated production.

04

Kitchenware & Home Appliance

Laser welding for cookware ensures fine, smooth seams without polishing, prevents distortion, maintains appearance, suits various metals, and enables automated, efficient production.

01

Step

Submit Requirements

Provide drawings, photos, videos, and basic project details to help us quickly understand your needs.

02

Step

Technical Evaluation

Our team analyzes your materials and proposes the most suitable laser or automation solution.

03

Step

Design & Production

We finalize the solution, start detailed design, and manufacture the required equipment.

04

Step

Delivery & Support

We install the system, train your team, and provide ongoing technical service.