About Laser

- Home

- > TrueSyn Laser welding robot-ABB series

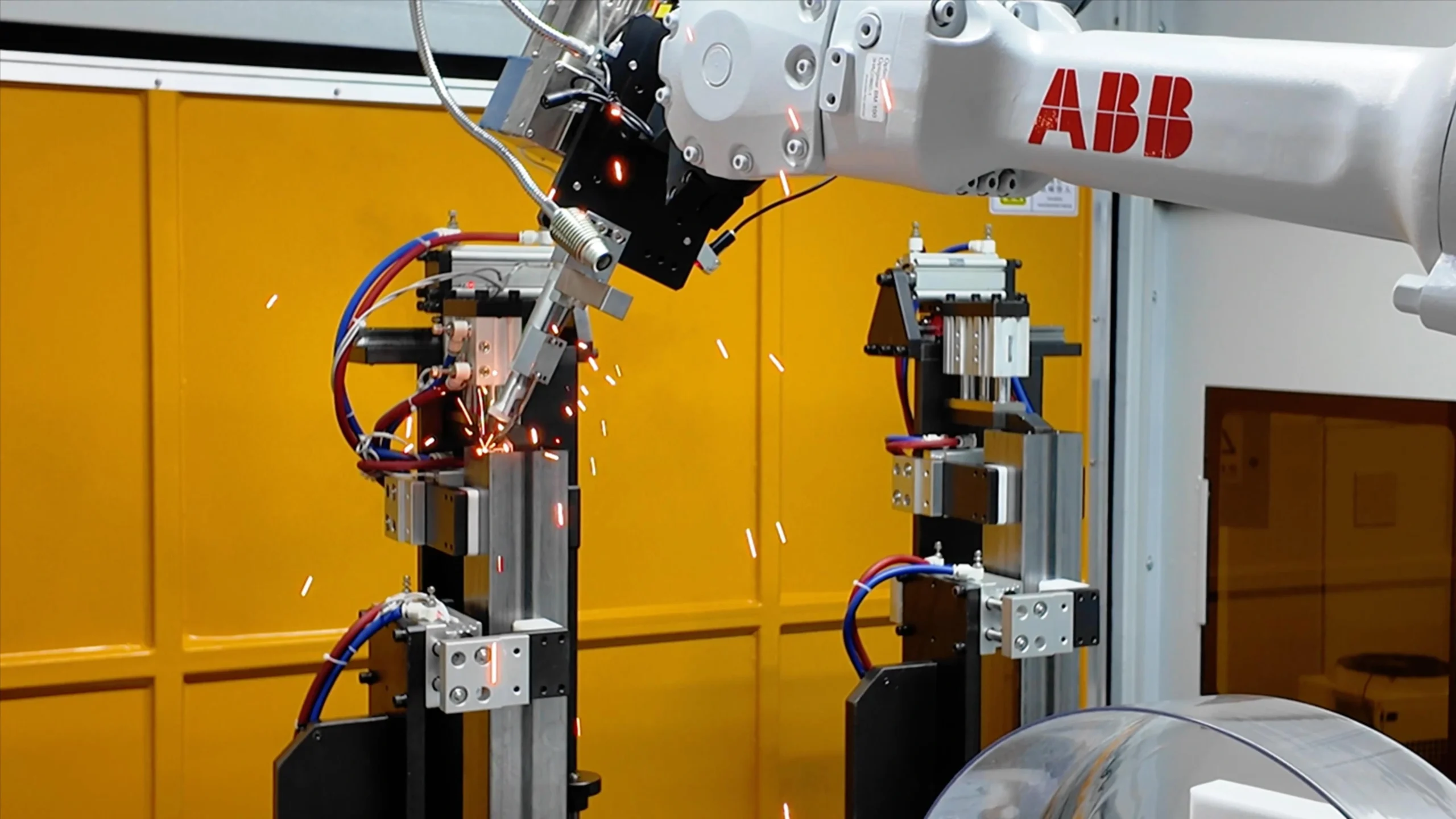

TrueSyn Laser welding robot-ABB series

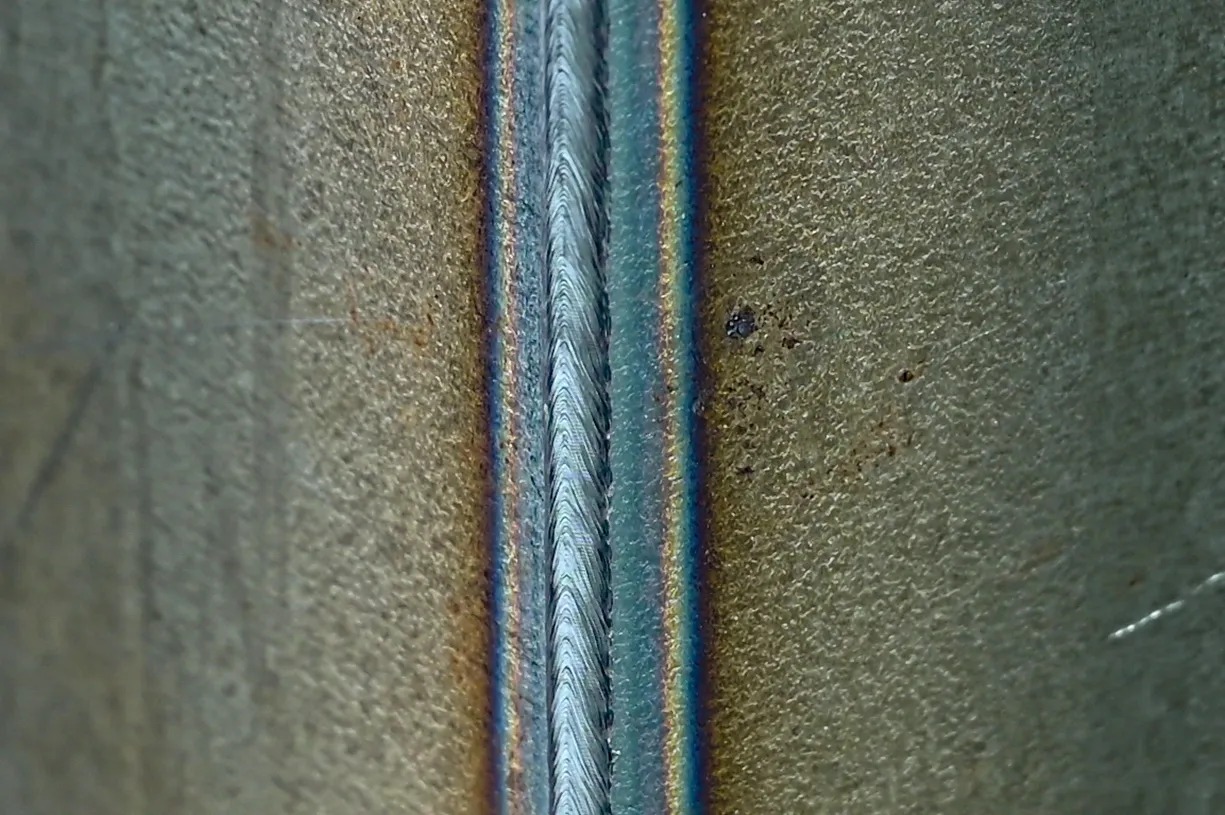

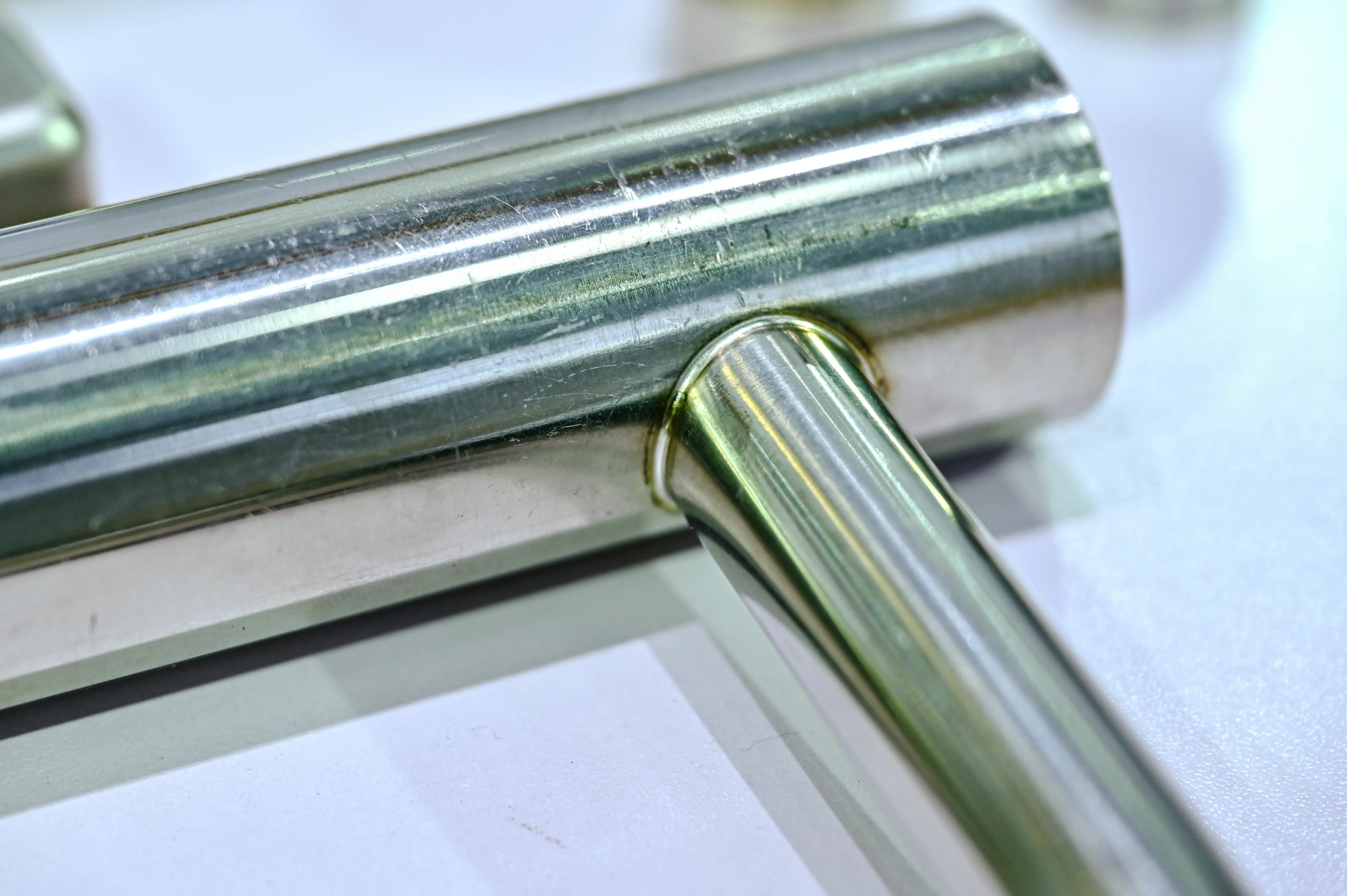

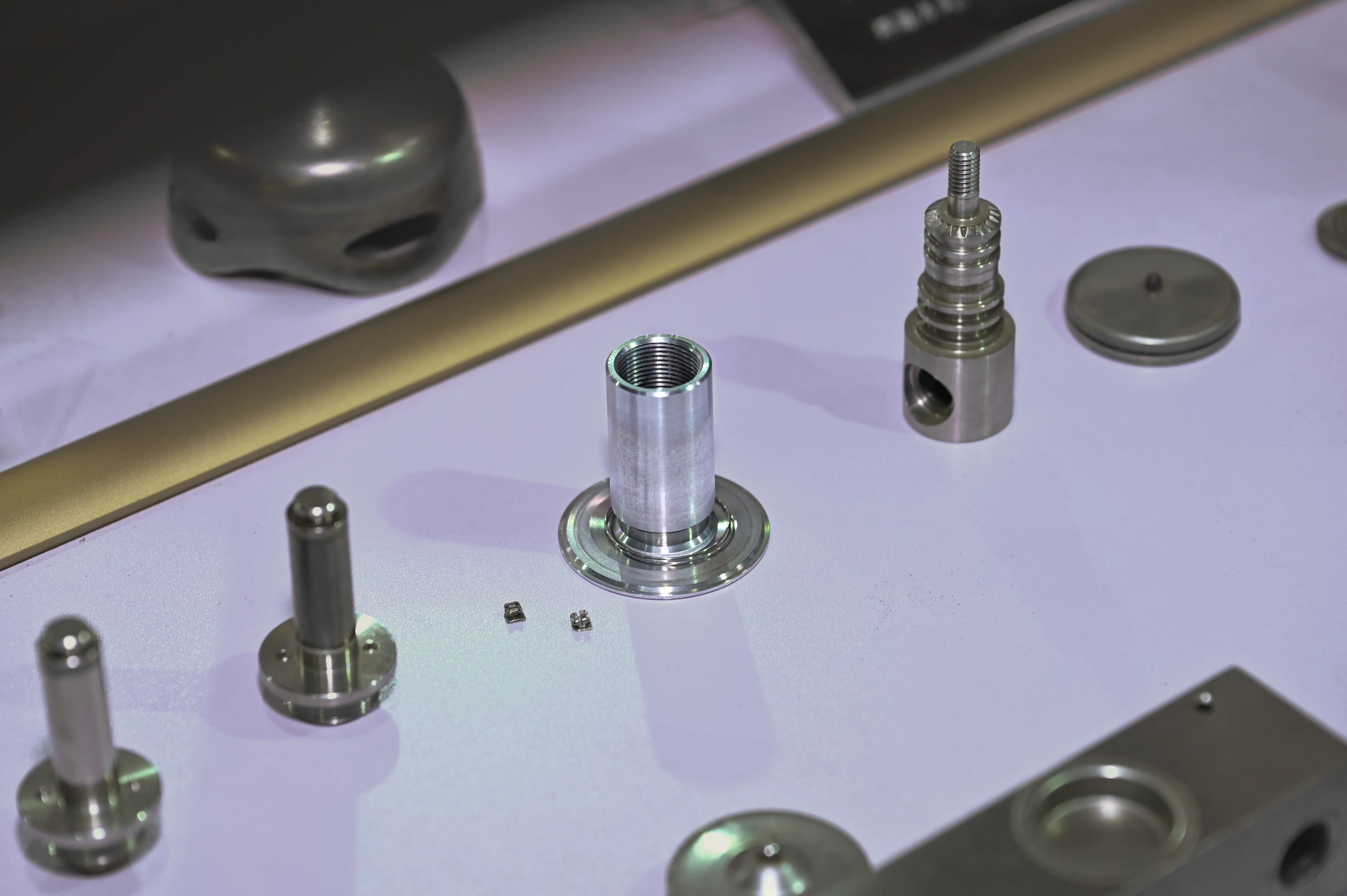

ABB laser welding robots combine extreme reliability and long service life with high-performance, internationally renowned laser sources. This robust solution is ideal for the kitchenware, home furnishings, and automotive industries. It excels in efficiently welding thin sheets under 6mm, ensuring high productivity, superior quality, and minimal distortion for a perfect finish.

Product Description

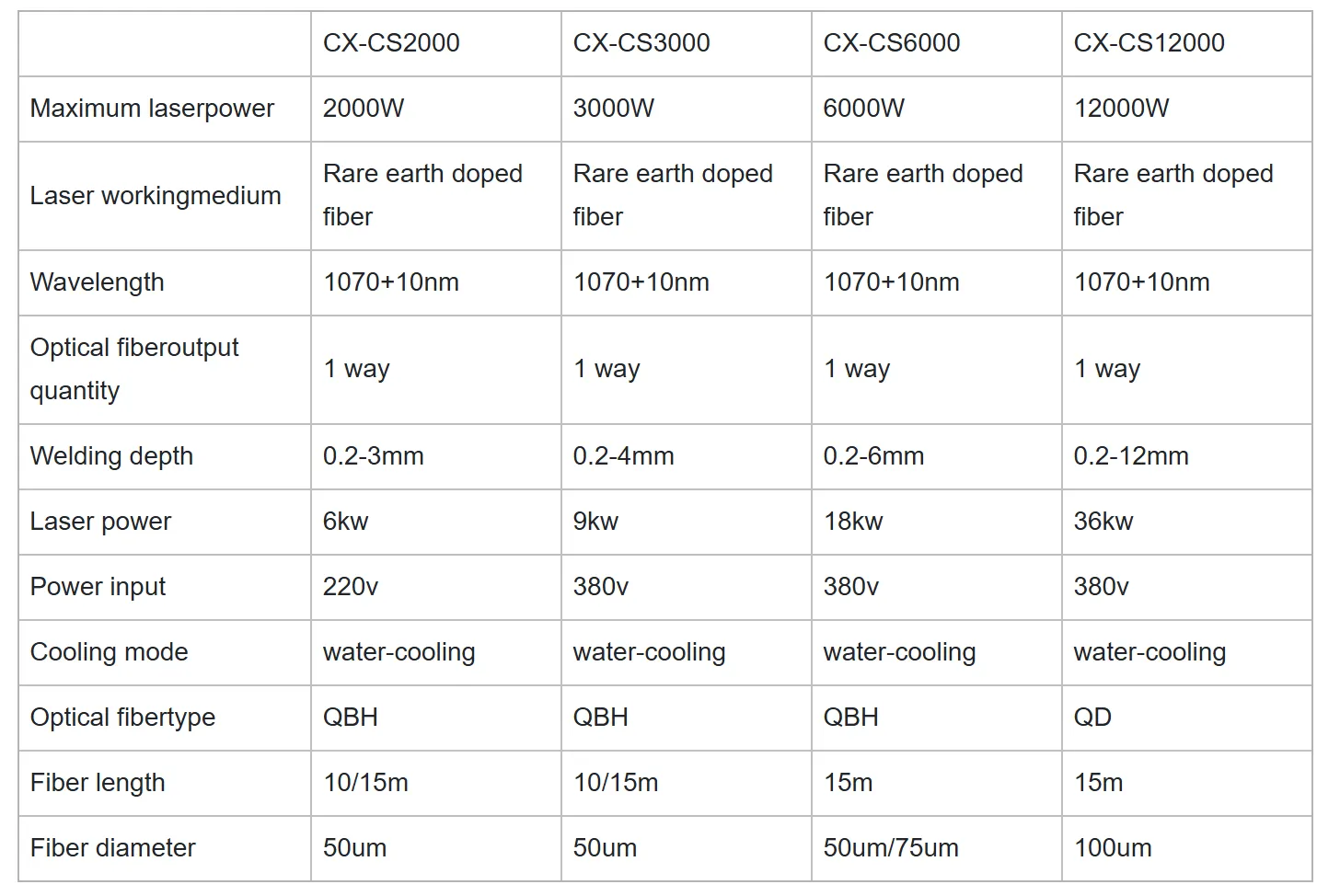

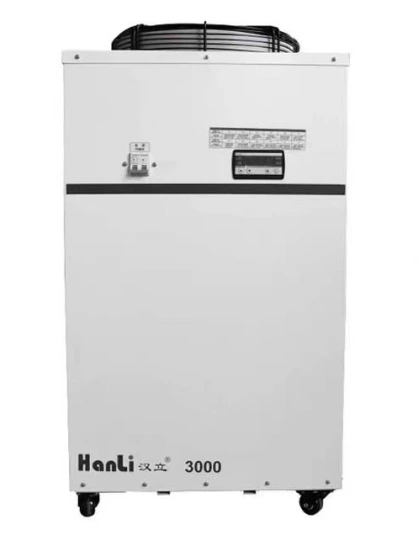

1.We could offer tailored postioners and fixtures according to the customer requirements(laser source optional 2000W, 3000W, 6000W, 12000W etc.);

2.Welding depth could go up to 12mm;

3.Safe enclosures keeps worker from laser radiation;

4. We corporate with Top Robot Brand like Yaskawa, ABB, Fanuc to make whole system more steadier and reliable;

- Power Demand: 380VAC,50/60 Hz

Specification

Automobile Industry

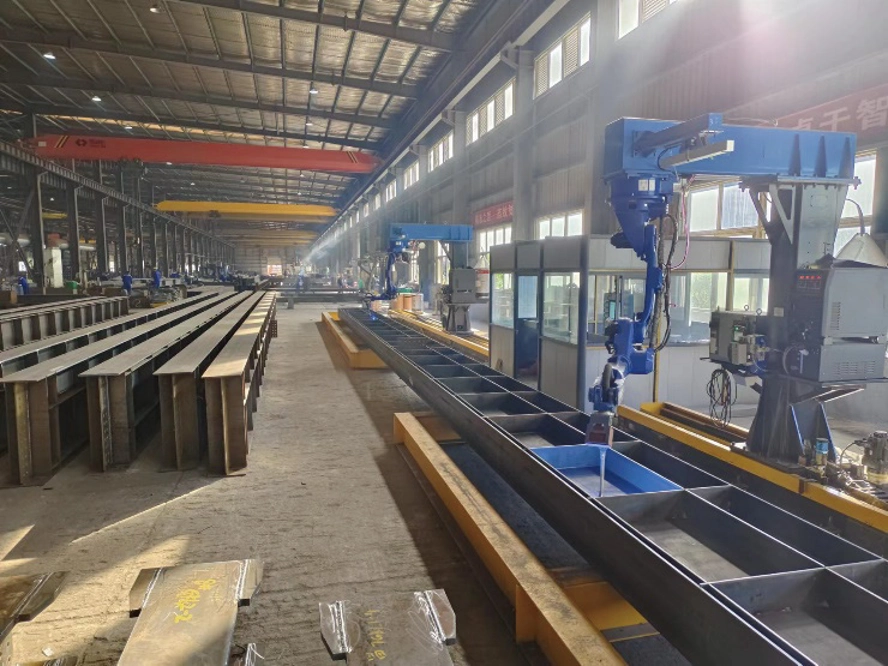

Construction & Steel industry

Electric Power industry

Kitchenware & Home Appliance

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.