About Laser

- Home

- > TrueSyn Bending Robot

TrueSyn Bending Robot

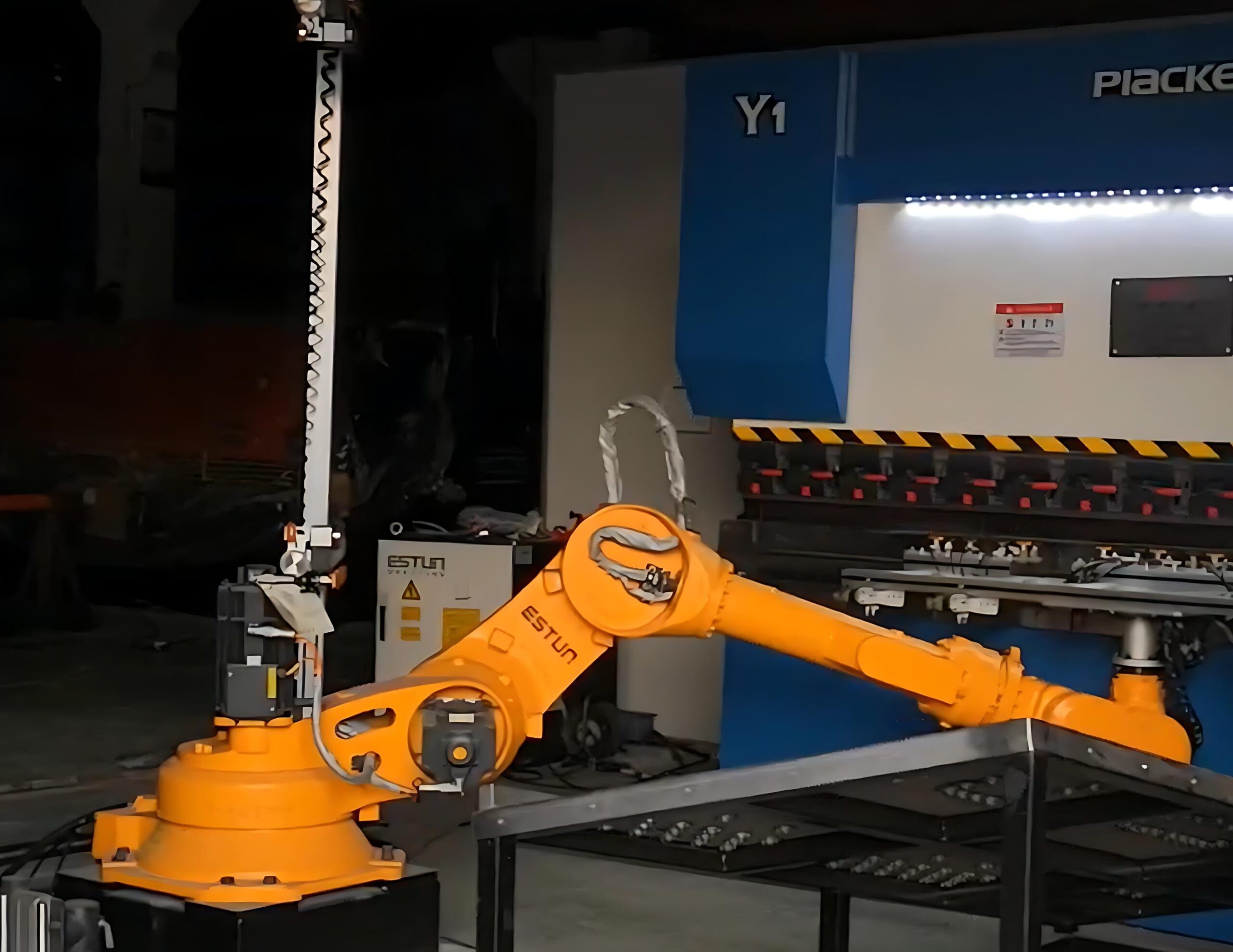

Our bending robots, with payloads from 40kg to 500kg, are versatile for various products. They operate tirelessly day and night, even in "lights-out" environments, truly boosting efficiency. They replace hazardous manual bending and can integrate with floor tracks for processing large, heavy items. An optional vision inspection system is available.All models are compatible with the Delem control system.

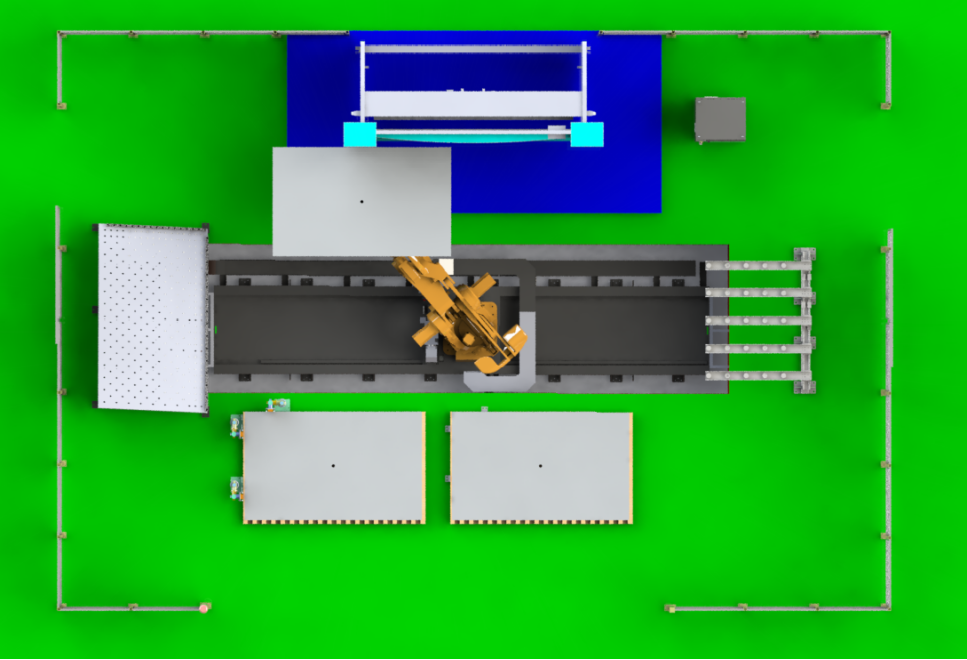

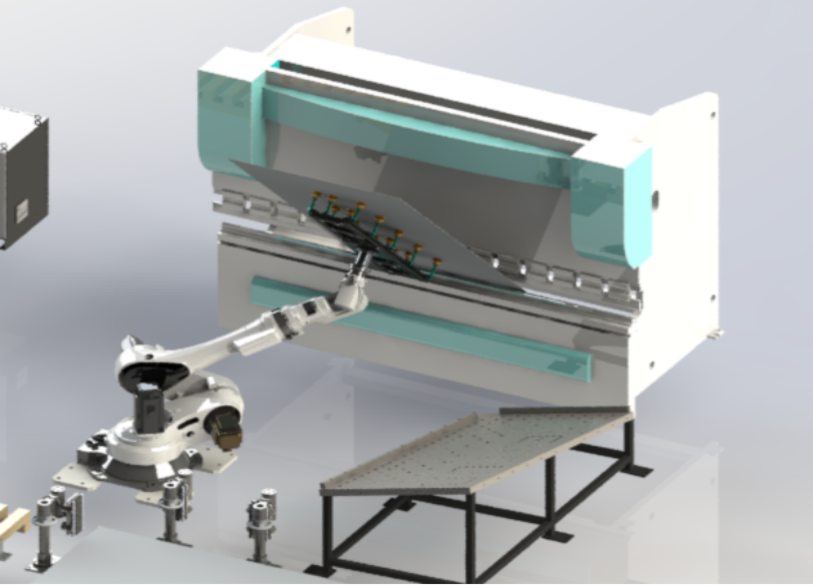

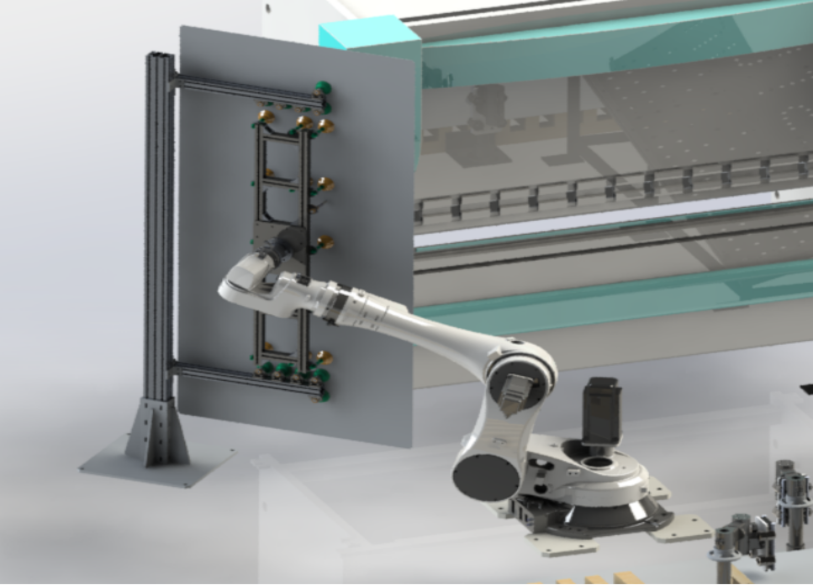

Solution 1

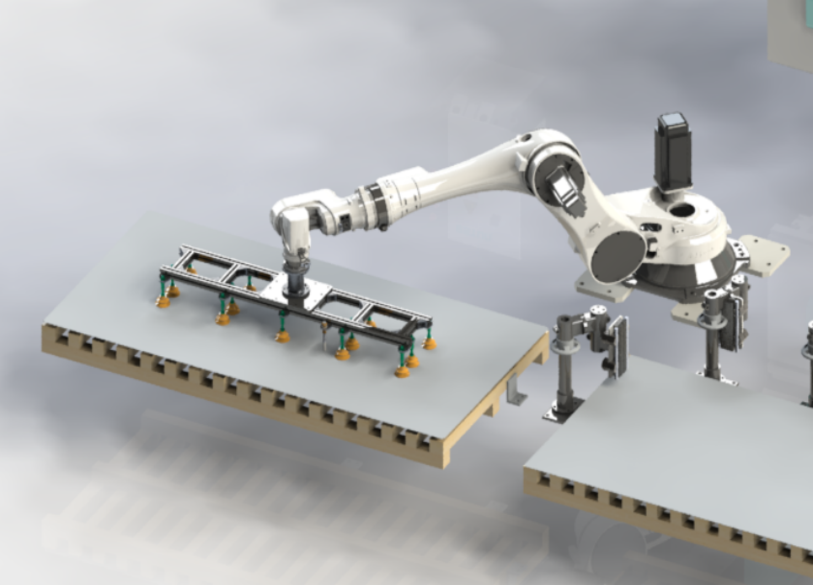

This bending-dedicated robot is specifically developed for large workpieces, addressing the limitations of using general-purpose robots for such applications and providing an optimal solution for robotic processing of large components.

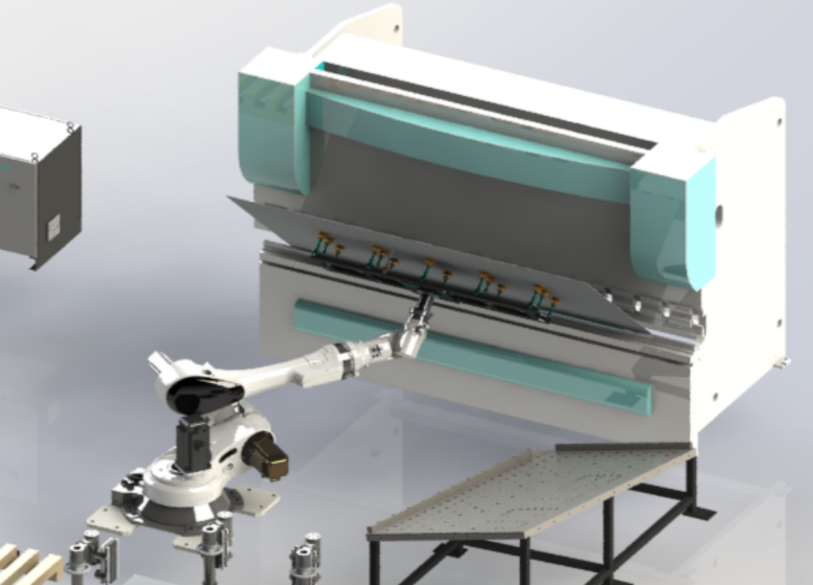

Solution 2

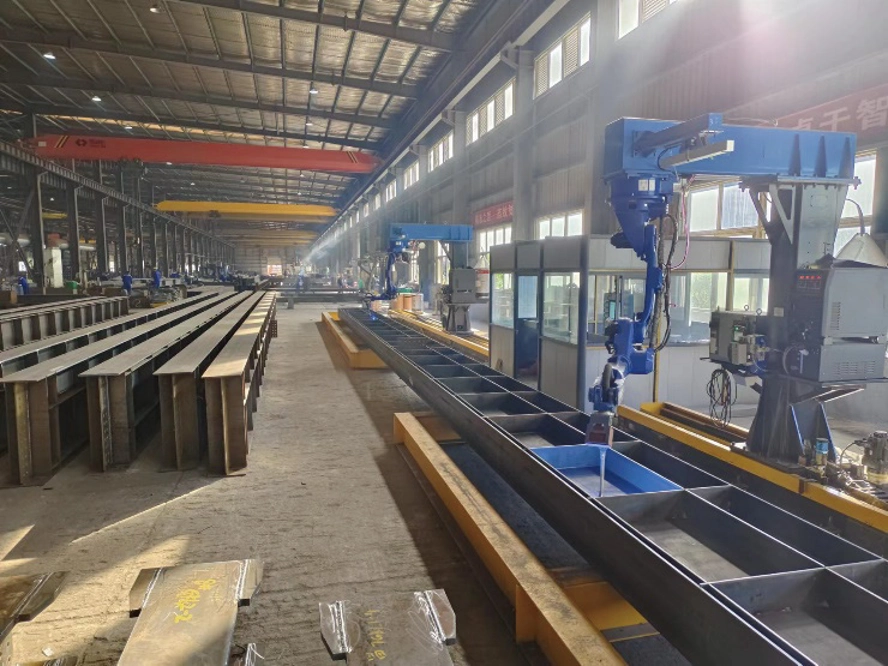

It solves the challenges of excessive human resource consumption and low efficiency in processing heavy and thick plates. By utilizing robots with 7axis floor track, it provides innovative solutions for heavy-gauge sheet metal processing.

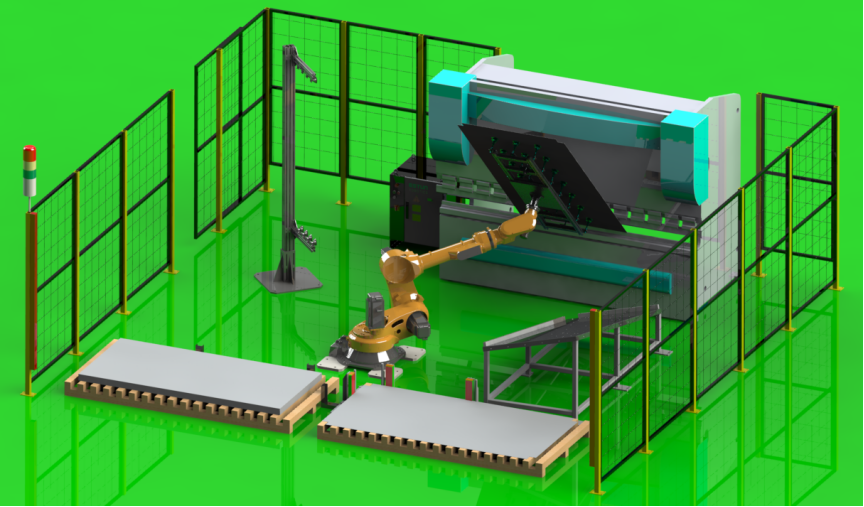

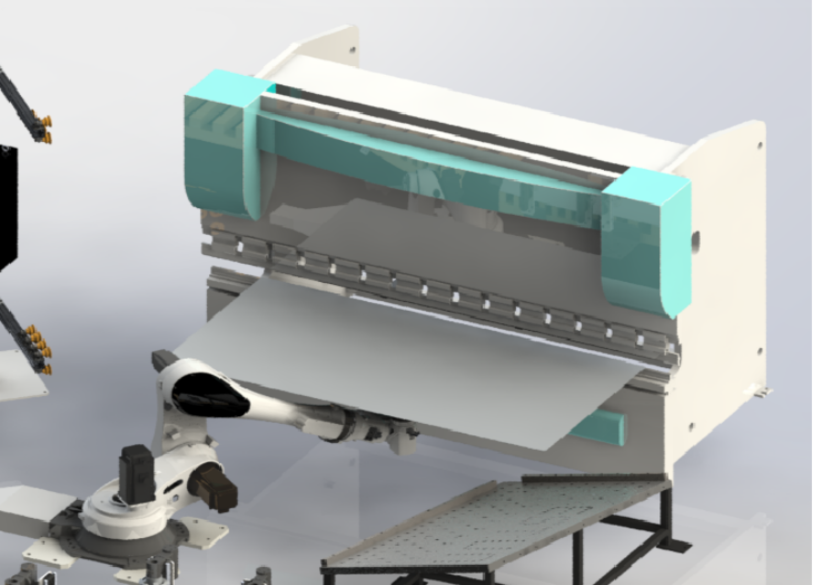

Bending Process

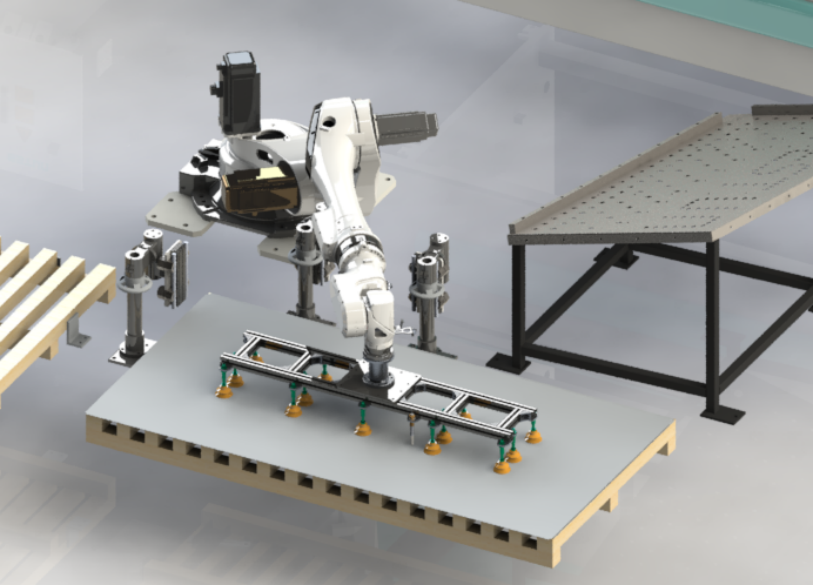

1 . Robot start working and grab work piece

2 . Put workpiece onto centering device

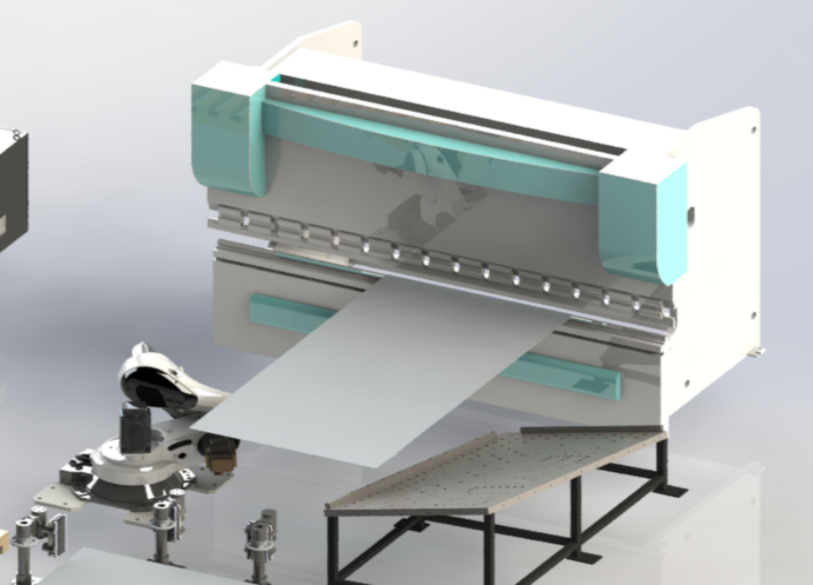

3.Robot feed work piece into press brake and back gauge positioning

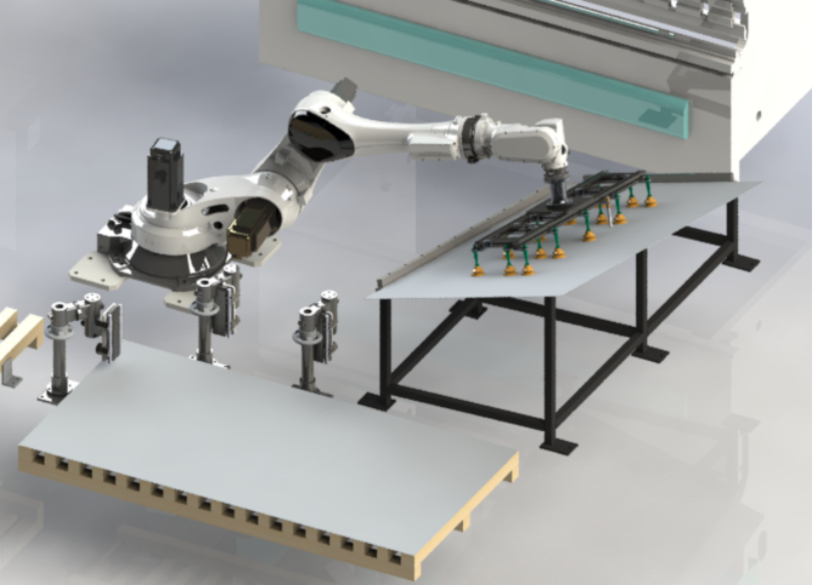

4.Robot processes work piece with press brake

5.Robot place work piece onto auto turning system and make turning

6.Robot feed work piece into press brake and back gauge positioning

7.Robot processes work piece with press brake

8.Robot place work piece onto output pallet