About Laser

- Home

- > Single Axis Flip Positioner

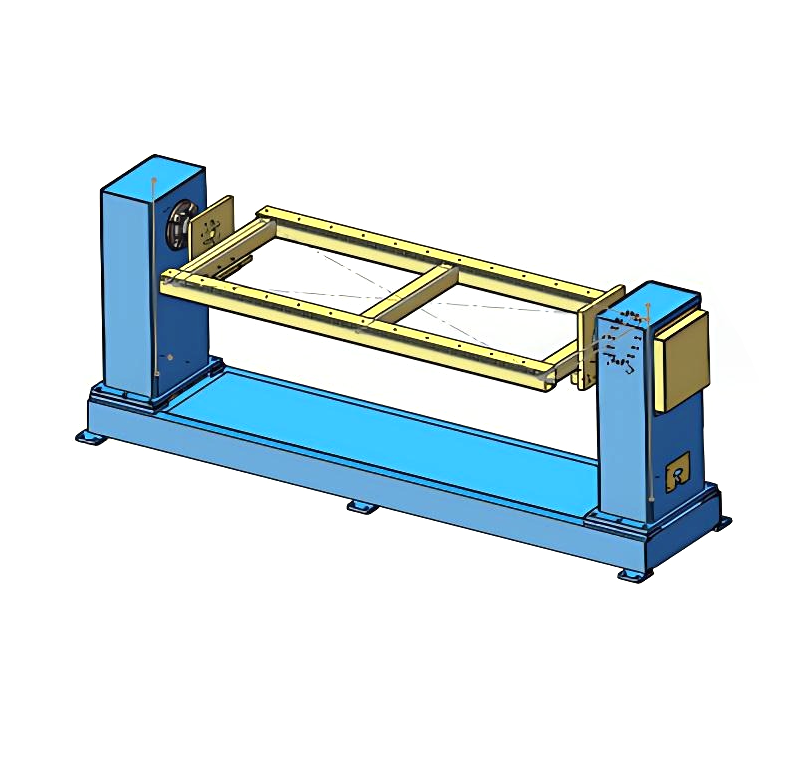

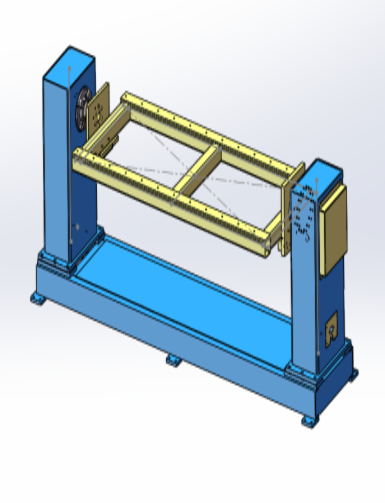

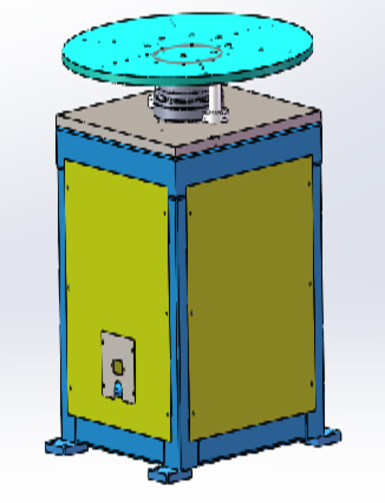

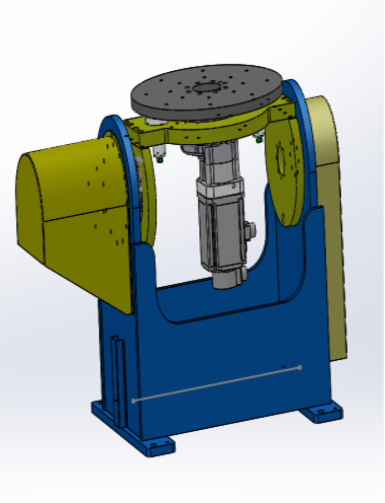

Single Axis Flip Positioner

Single Axis Flip Positioner

Customization Options

To better meet the diverse needs of different application scenarios, the CX-1FZ series provides the following customization services:

- Load Capacity Customization: According to the actual weight of the workpiece, customized load capacity designs can be provided beyond the standard 300/500/1000 kg, with a common customizable range of 1500–2000 kg.

- Frame & Dimension Adjustment: The frame size (L*W*H) and swing radius can be tailored to fit the installation space of the production site or the specific dimensions of the workpiece, ensuring seamless integration into existing production lines.

- Reducer & Speed Configuration: Alternative RV reducer models can be selected, and the rated/maximum rotation speed ranges can be adjusted to match the motion rhythm requirements of different processing or testing procedures.

- Accuracy & Accessory Upgrade: Higher repeat positioning accuracy (e.g., ±0.5 arcmin) can be achieved through precision optimization. Additionally, optional accessories such as position limit sensors, emergency stop devices, and safety guards can be equipped to enhance operational safety and convenience.

- Environmental Adaptation Modification: For special working environments, sealed enclosures can be added to achieve dustproof and waterproof effects, or heat-resistant materials can be used to adapt to high-temperature operating conditions.

Application Cases

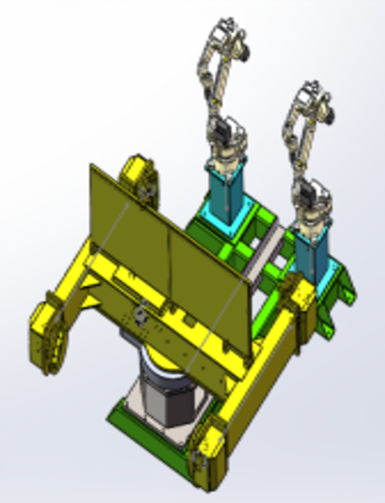

- Industrial Welding & Assembly

Widely used in automotive and mechanical part production lines. It can flip workpieces such as chassis, metal frames, and mechanical casings to preset angles, allowing robotic arms to perform welding, riveting, screw locking, and assembly operations from multiple directions. This not only improves the efficiency of the assembly process but also ensures the consistency and quality of the connection points.

- Aerospace Component Testing

Applied in the testing of aerospace components such as aircraft wing segments, cabin components, and satellite structural parts. It simulates the flipping posture of components in actual working conditions within environmental test chambers (e.g., high and low temperature chambers, humidity chambers), verifying the structural stability, fatigue resistance, and functional reliability of the components under repeated flip motions.

- Material Processing & Coating

Used in the surface processing of large workpieces such as metal plates, composite material panels, and furniture parts. During coating, sandblasting, polishing, or spraying processes, the positioner flips and rotates the workpiece to ensure that all surfaces are uniformly processed, avoiding uneven coating or missed processing caused by fixed workpiece positions.

- Medical Equipment Manufacturing

Involved in the assembly and testing of precision medical equipment such as diagnostic scanners, surgical robots, and rehabilitation devices. It flips components like surgical instrument frames, scanner rotating arms, and medical device casings, ensuring accurate alignment and fitting of moving parts, and meeting the strict precision and safety standards of the medical industry.

- Logistics & Handling Systems

Integrated into automated logistics and warehousing systems. It flips heavy cargo such as large containers, industrial packaging boxes, and mechanical parts during loading, unloading, and sorting processes. This reduces the reliance on manual labor, improves the efficiency of logistics operations, and minimizes the risk of cargo damage caused by manual handling.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.