About Laser

- Home

- > MIG Welding Cobot

MIG Welding Cobot

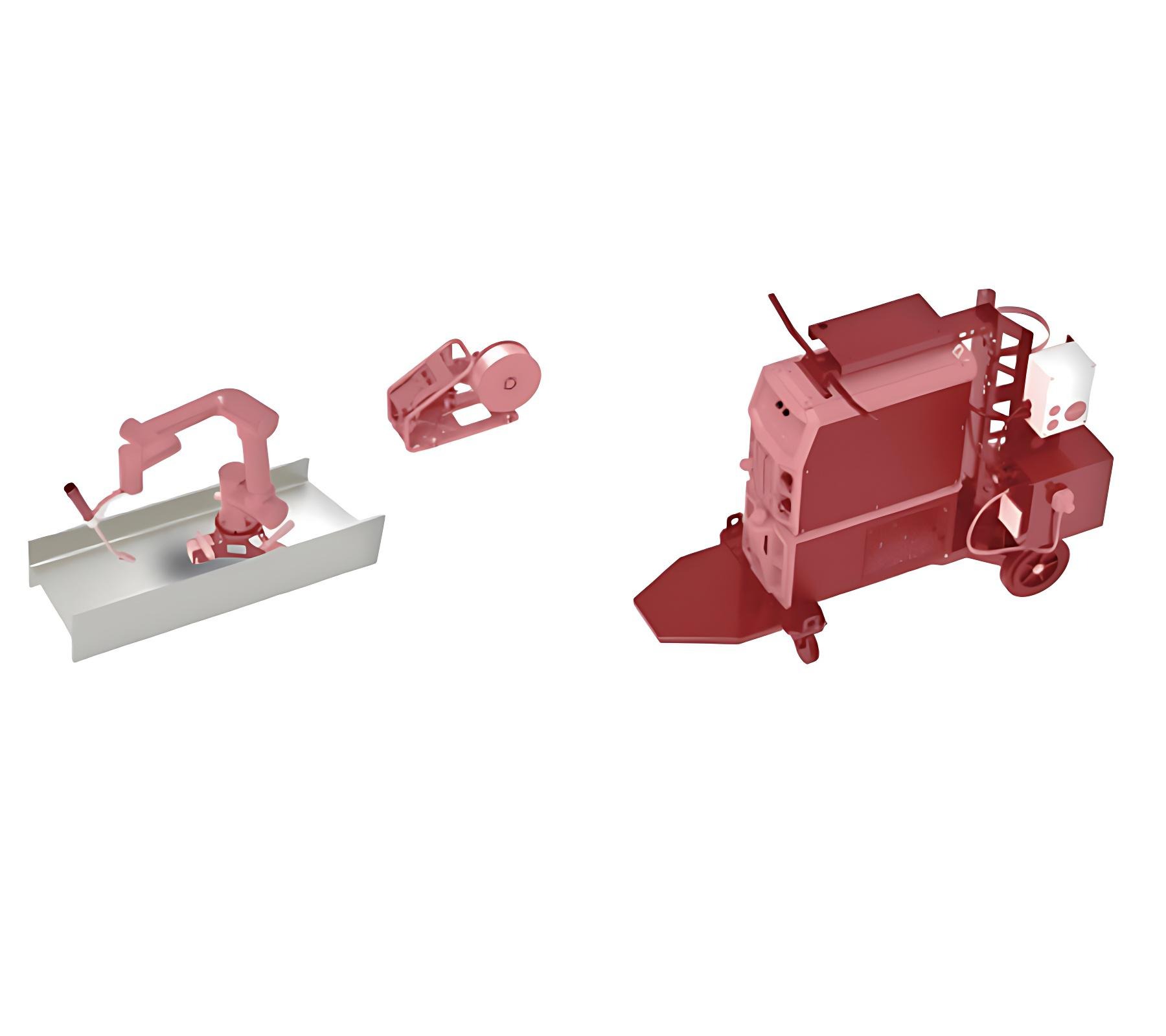

Our Innovation Laser Welding Cobot System: Integrated intelligent equipment with 2 core cobots (FR5: 5kg, 922mm, ±0.02mm; FR10: 10kg, 1400mm, ±0.05mm), Ehave2 MIG/MAG welders (350A-630A, multi-process), force sensors (safety/precision), Smart Tool (3s start, 5min mastery) and magnetic trolleys. Fits small-to-medium workpieces; for auto, machinery, electronics automation.

Innovationlaser@zjcxlaser.com

FR Cobot + MIG Welding System

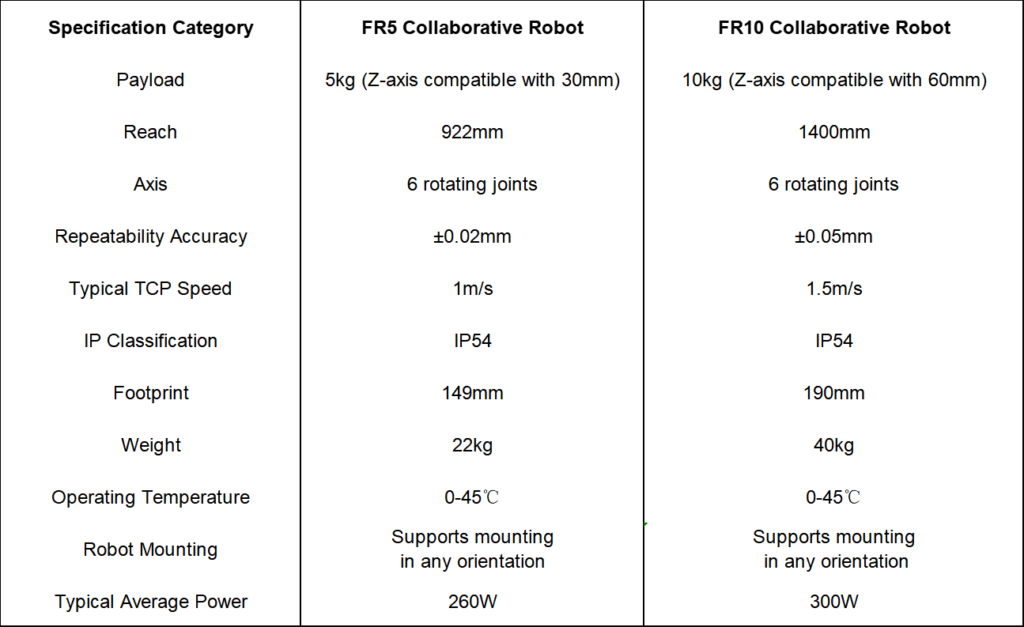

Innovation Laser’s Welding Cobot System boasts two high-performance core cobots:

- FR5: Lightweight with 5kg payload, 922mm reach and ±0.02mm precision—ideal for high-accuracy small-part welding.

- FR10: Medium-payload (10kg) with 1400mm long reach—perfect for medium-large workpieces.

Both offer flexible mounting, IP54 workshop protection and clear specs, ensuring multi-scenario automation efficiency.

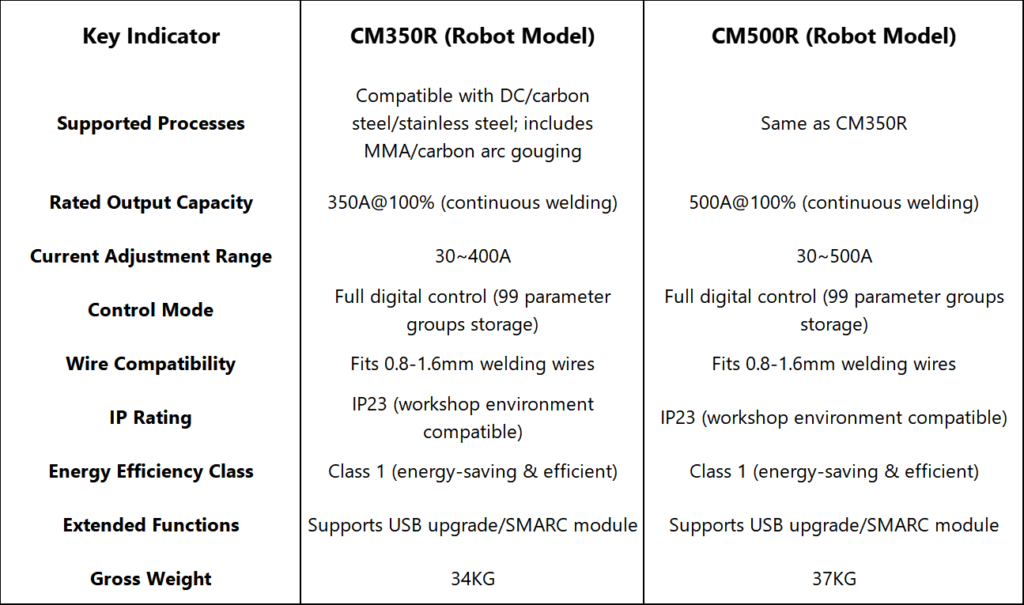

Innovation Laser’s Ehave2 CM350R/500R MIG welding system—a fully digitally controlled welder designed for collaborative robot operations:

- It supports multiple processes (DC, carbon steel/stainless steel welding, MMA, carbon arc gouging, etc.). The CM350R has a 350A rated output, while the CM500R reaches 500A; both support parameter storage and USB upgrades.

- With an IP23 protection rating, it’s suited for workshop environments. As the core power unit of the robotic welding system, it covers welding needs from small-medium to medium-large workpieces.

01

Automobile Industry

Laser welding enables high-precision, high-speed automotive manufacturing with minimal distortion, supports diverse materials, and enhances strength, durability, and aesthetics through automation.

02

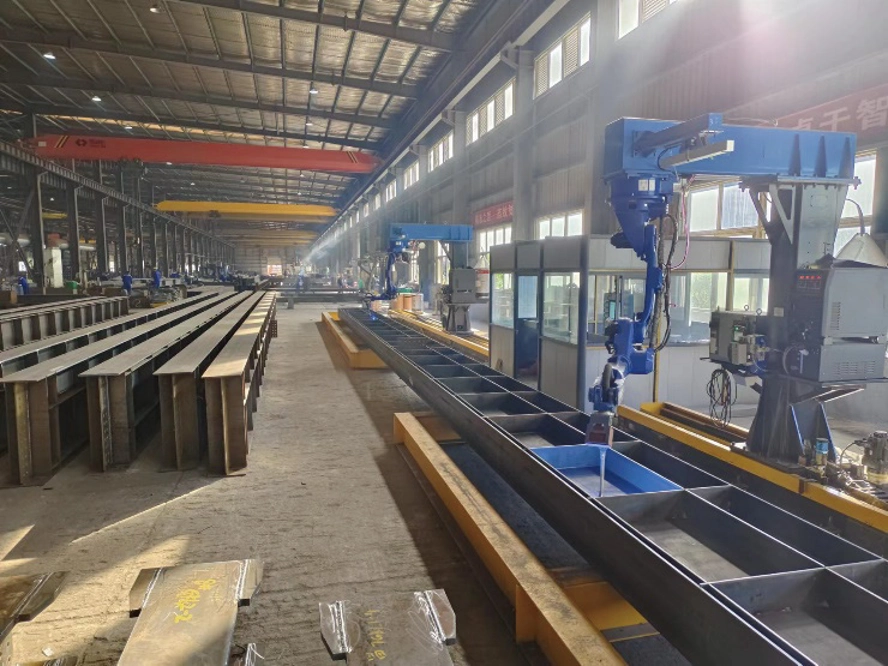

Construction & Steel industry

Programming-free arc welding robots in steel structures use vision and AI for adaptive welding. They auto-identify seams, plan paths, reduce manual work, handle tolerances, and boost quality and efficiency for flexible, small-batch production.

03

Electric Power industry

Laser welding robots for GIS/RMU ensure airtight seams with high precision, minimal distortion, and consistent strength, enhancing safety and reliability through automated production.

04

Kitchenware & Home Appliance

Laser welding for cookware ensures fine, smooth seams without polishing, prevents distortion, maintains appearance, suits various metals, and enables automated, efficient production.

01

Step

Submit Requirements

Provide drawings, photos, videos, and basic project details to help us quickly understand your needs.

02

Step

Technical Evaluation

Our team analyzes your materials and proposes the most suitable laser or automation solution.

03

Step

Design & Production

We finalize the solution, start detailed design, and manufacture the required equipment.

04

Step

Delivery & Support

We install the system, train your team, and provide ongoing technical service.

Contact

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.