About Laser

- Home

- > Laser Protective Encloures

Laser Protective Enclosures

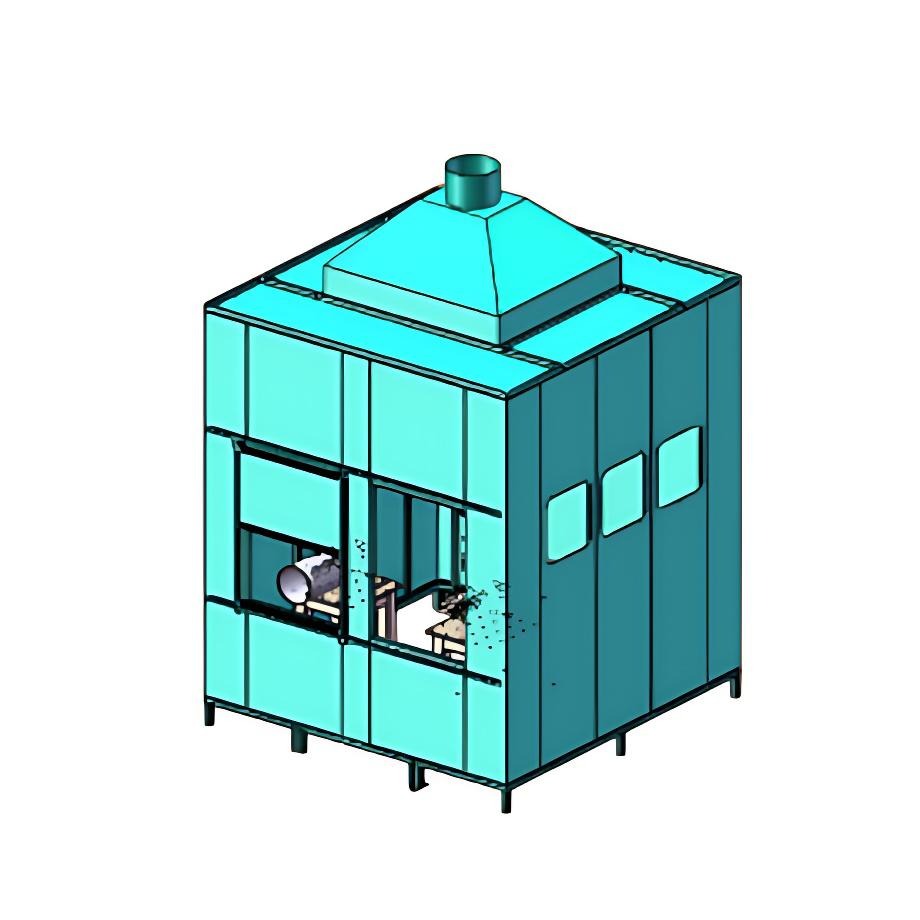

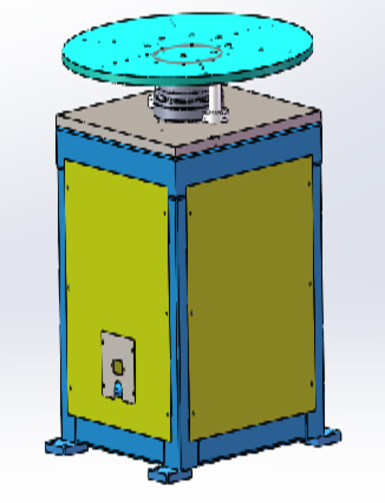

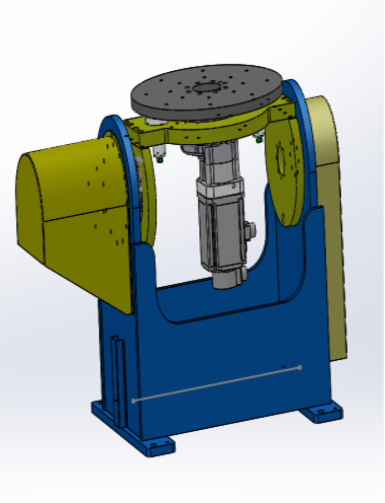

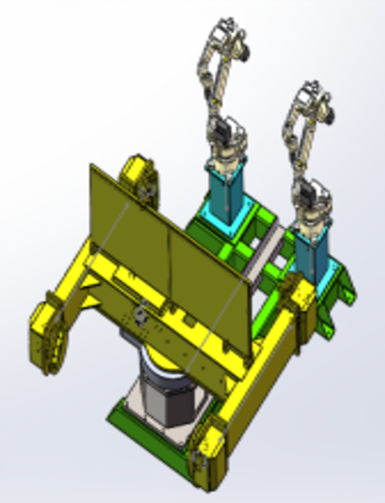

Laser Protective Enclosures (LPE) are safety devices compliant with laser safety standards, designed to shield operators and surrounding equipment from laser radiation, metal spatter, processing dust, and other hazards. They also maintain a clean processing environment to ensure machining precision.

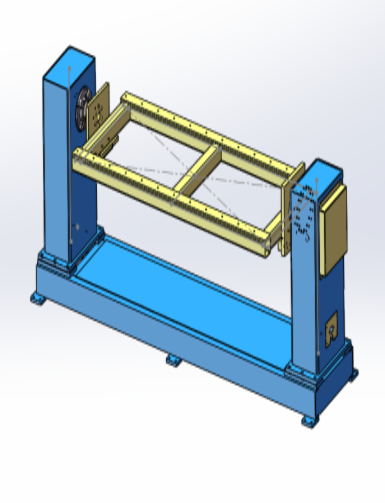

- Core Structure & Materials: Typically feature a modular design, with common materials including aluminum alloy, coated stainless steel, and laser-resistant acrylic. Flexible materials like flame-retardant nylon fabric are used for specialized scenarios.

- Laser Shielding Performance: Customizable for laser wavelengths ranging from 200nm to 2000nm, adhering to international safety standards such as EN IEC 60825-4. Most products achieve Laser Class 1 protection, meeting safety requirements for industrial production, scientific research, and other applications.

- Key Components: Equipped with interlock systems (cutting off laser power instantly when the door is opened), high-definition observation windows (blocking harmful laser while ensuring operational visibility), and ventilation ports (expelling smoke and dust generated during processing).

Innovationlaser@zjcxlaser.com

Laser Protective Enclosures (LPE) are safety devices compliant with laser safety standards, designed to shield operators and surrounding equipment from laser radiation, metal spatter, processing dust, and other hazards. They also maintain a clean processing environment to ensure machining precision.

- Core Structure & Materials: Typically feature a modular design, with common materials including aluminum alloy, coated stainless steel, and laser-resistant acrylic. Flexible materials like flame-retardant nylon fabric are used for specialized scenarios.

- Laser Shielding Performance: Customizable for laser wavelengths ranging from 200nm to 2000nm, adhering to international safety standards such as EN IEC 60825-4. Most products achieve Laser Class 1 protection, meeting safety requirements for industrial production, scientific research, and other applications.

- Key Components: Equipped with interlock systems (cutting off laser power instantly when the door is opened), high-definition observation windows (blocking harmful laser while ensuring operational visibility), and ventilation ports (expelling smoke and dust generated during processing).

Innovationlaser@zjcxlaser.com

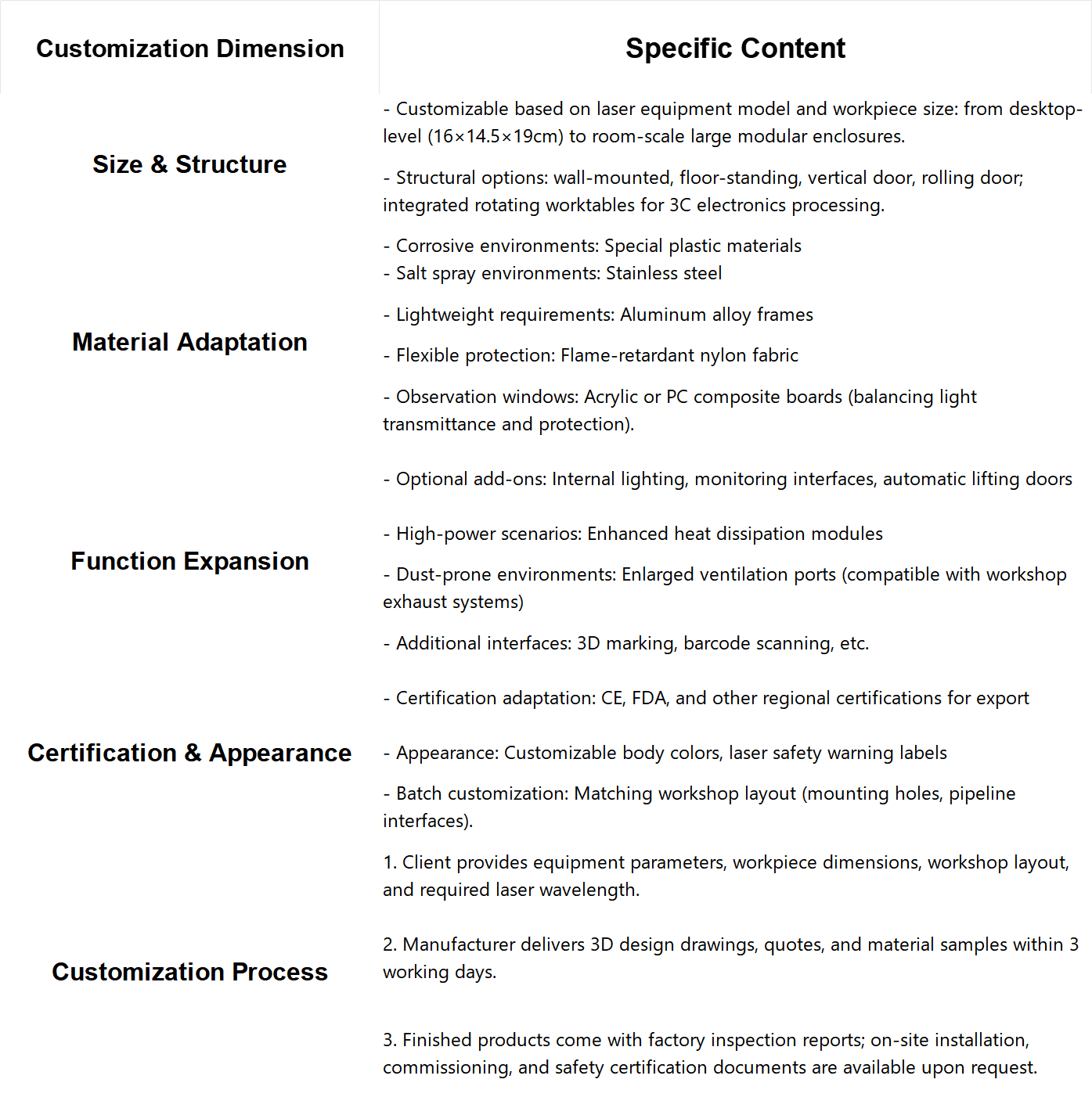

Customization Options

01

Step

Submit Requirements

Provide drawings, photos, videos, and basic project details to help us quickly understand your needs.

02

Step

Technical Evaluation

Our team analyzes your materials and proposes the most suitable laser or automation solution.

03

Step

Design & Production

We finalize the solution, start detailed design, and manufacture the required equipment.

04

Step

Delivery & Support

We install the system, train your team, and provide ongoing technical service.

Contact

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.