About Laser

- Home

- > Dual Axis U Type Positioner

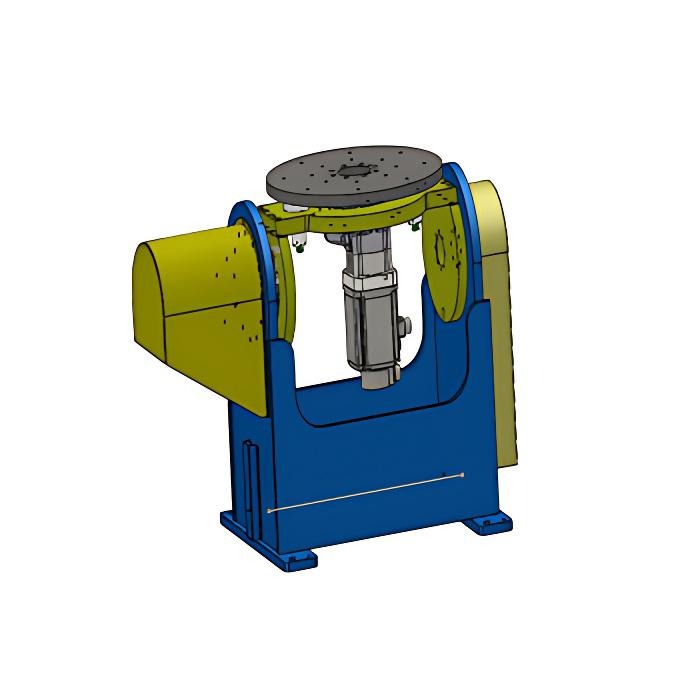

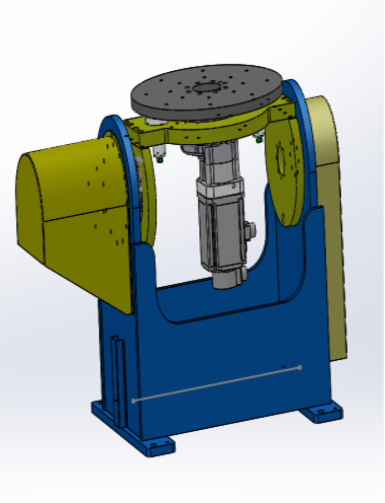

Dual Axis U Type Positioner

Customization Options

- The CX-2SP series supports the following customizable details:

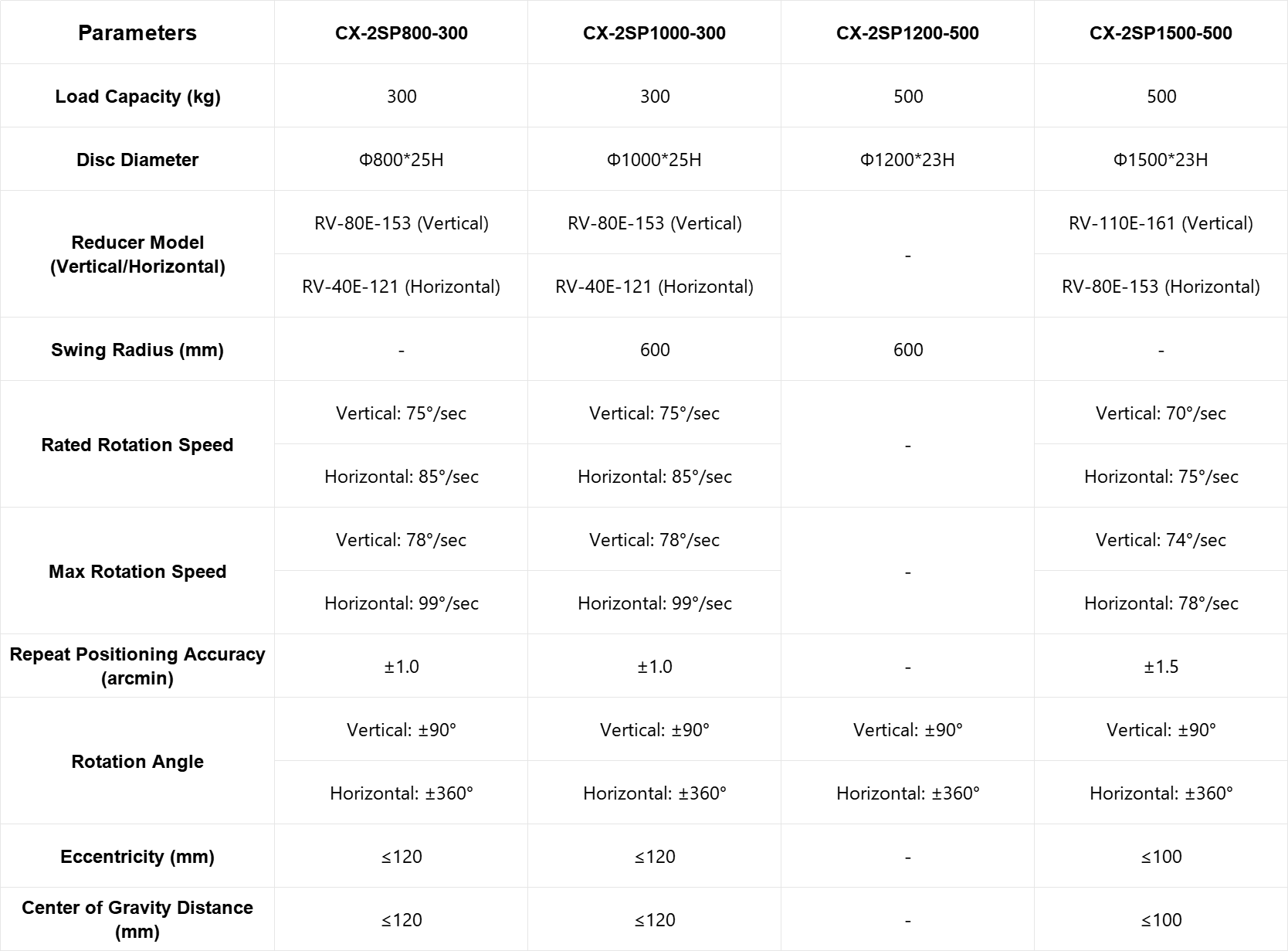

- Load Capacity: Tailored designs for load ranges beyond 300/500 kg (e.g., 800–1200 kg) based on workpiece weight.

- Disc & Structure: Custom disc diameter (Φ600–Φ2000), thickness, and surface treatment (e.g., anti-slip coating, precision positioning holes).

- Dual-Axis Motion: Adjustable rotation speed/range for vertical/horizontal axes, or higher precision (e.g., ±0.8 arcmin) for precision testing scenarios.

- Reducer & Accessories: Alternative reducer models, or additional accessories (e.g., angle sensors, safety interlocks, remote control modules).

- Environmental Adaptation: Sealed enclosures for dust/waterproof needs, or low-temperature-resistant materials for special working environments.

Application Cases

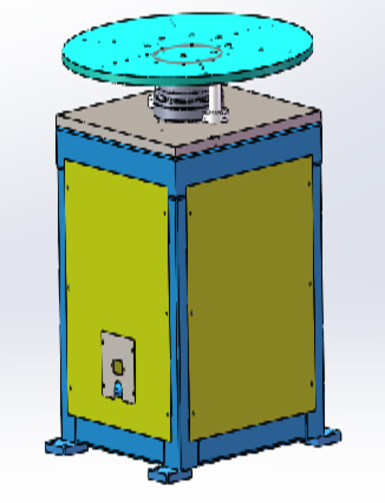

- Precision Component Testing

Applied in aerospace/electronic component testing: enables dual-axis rotation of parts (e.g., satellite sensors, avionics modules) to simulate multi-angle working postures, verifying performance stability under complex motion conditions.

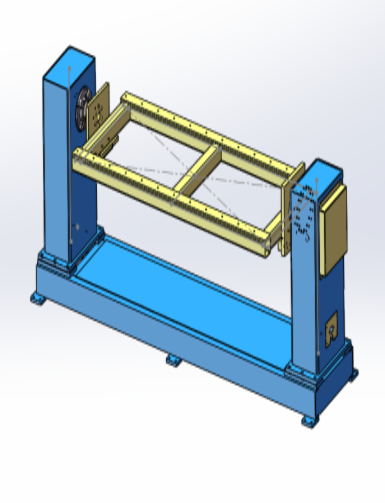

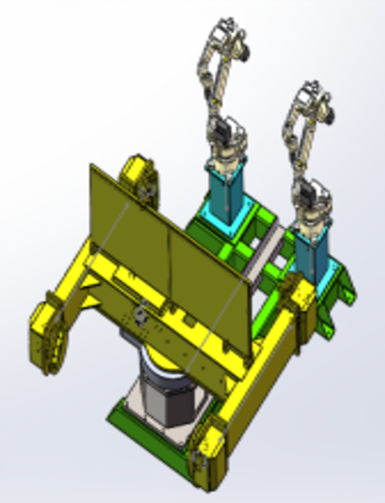

- Multi-Angle Welding & Coating

Integrated into automotive/metal processing lines: flips/rotates workpieces (e.g., car body frames, metal brackets) via dual axes, allowing welding robots or coating equipment to process all surfaces uniformly, improving processing efficiency and quality.

- Optical Equipment Calibration

Used for calibrating high-precision optical devices (e.g., laser rangefinders, imaging lenses): adjusts the angle of optical components via dual-axis rotation, ensuring accurate alignment of light paths and optimizing device measurement accuracy.

- Medical Device Assembly

Involved in assembling complex medical equipment (e.g., surgical navigation systems, diagnostic probes): positions precision parts (e.g., sensor modules, mechanical arms) via dual-axis rotation, ensuring accurate fitting of multi-directional components.

- Industrial Robot Matching

Matched with collaborative robots: provides dual-axis rotational positioning for workpieces (e.g., mechanical parts, electronic assemblies), enabling robots to complete multi-angle picking, placing, and processing operations in flexible production lines.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.