About Laser

- Home

- > YASKAWA MIG/MAG Welding Robot

YASKAWA MIG/MAG Welding Robot Integrated System

YASKAWA AR 1440/2010+ 350A/500A Welding System

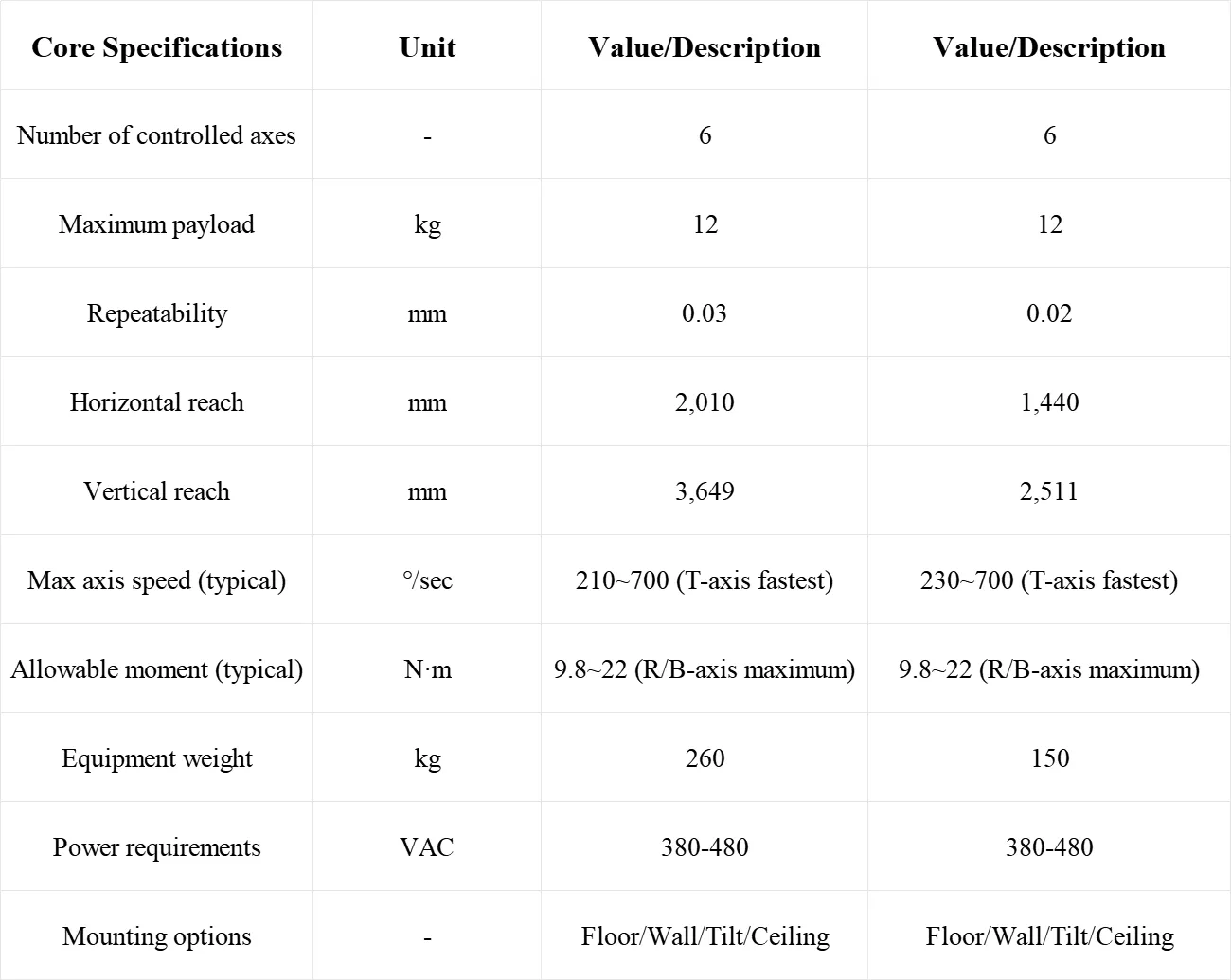

Core Specifications | Unit | Value/Description | Value/Description |

Number of controlled axes | – | 6 | 6 |

Maximum payload | kg | 12 | 12 |

Repeatability | mm | 0.03 | 0.02 |

Horizontal reach | mm | 2,010 | 1,440 |

Vertical reach | mm | 3,649 | 2,511 |

Max axis speed (typical) | °/sec | 210~700 (T-axis fastest) | 230~700 (T-axis fastest) |

Allowable moment (typical) | N·m | 9.8~22 (R/B-axis maximum) | 9.8~22 (R/B-axis maximum) |

Equipment weight | kg | 260 | 150 |

Power requirements | VAC | 380-480 | 380-480 |

Mounting options | – | Floor/Wall/Tilt/Ceiling | Floor/Wall/Tilt/Ceiling |

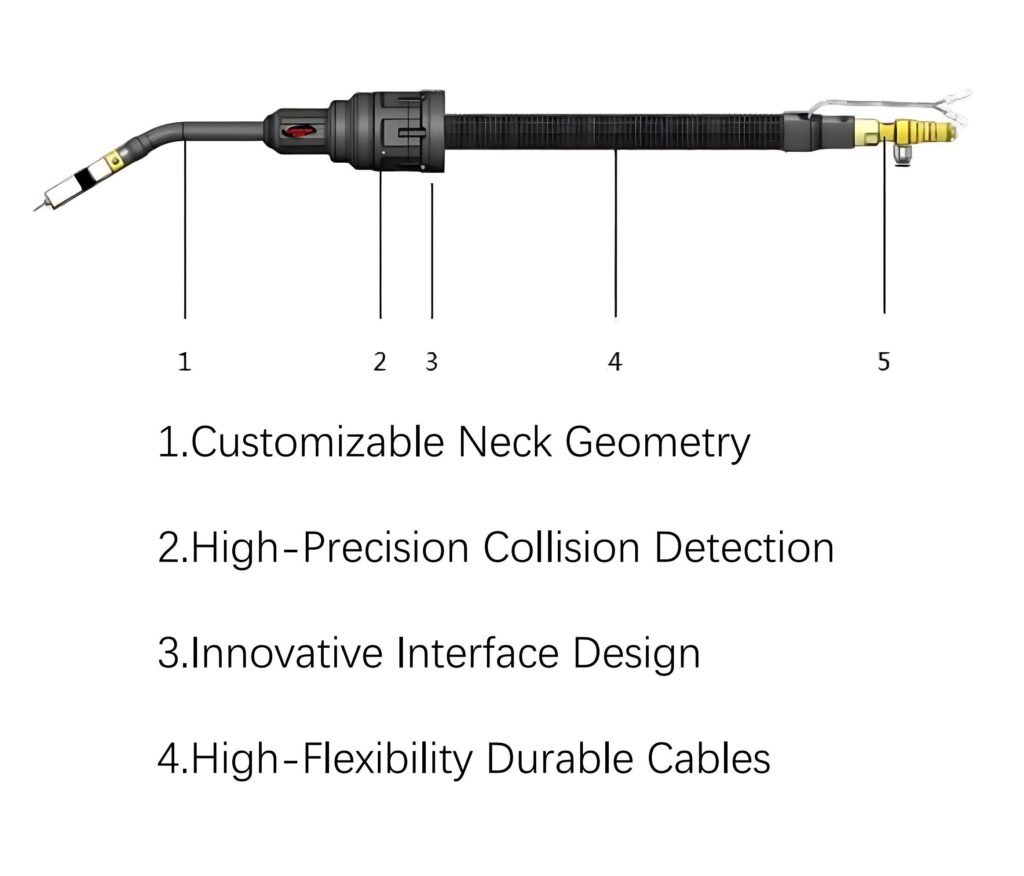

- Customizable Neck Geometry:The bent neck part can be adjusted in shape to adapt to different welding positions (e.g., narrow spaces), improving operational flexibility.

- High-Precision Collision Detection:The sensor-equipped interface area (Component 2) can quickly detect collisions, reducing damage to the gun and workpiece.

- Innovative Interface Design:The connection structure (Component 3) enables quick assembly/disassembly, simplifying maintenance and replacement.

- High-Flexibility Durable Cables:The main cable (Component 4) has strong flexibility and wear resistance, suitable for long-term repeated bending in automated welding scenarios.

- Air Cooling System:The internal structure (matched with the cable and connector) relies on airflow to cool the gun body, ensuring stable performance during continuous welding (lightweight and easy to maintain compared to water-cooled types).

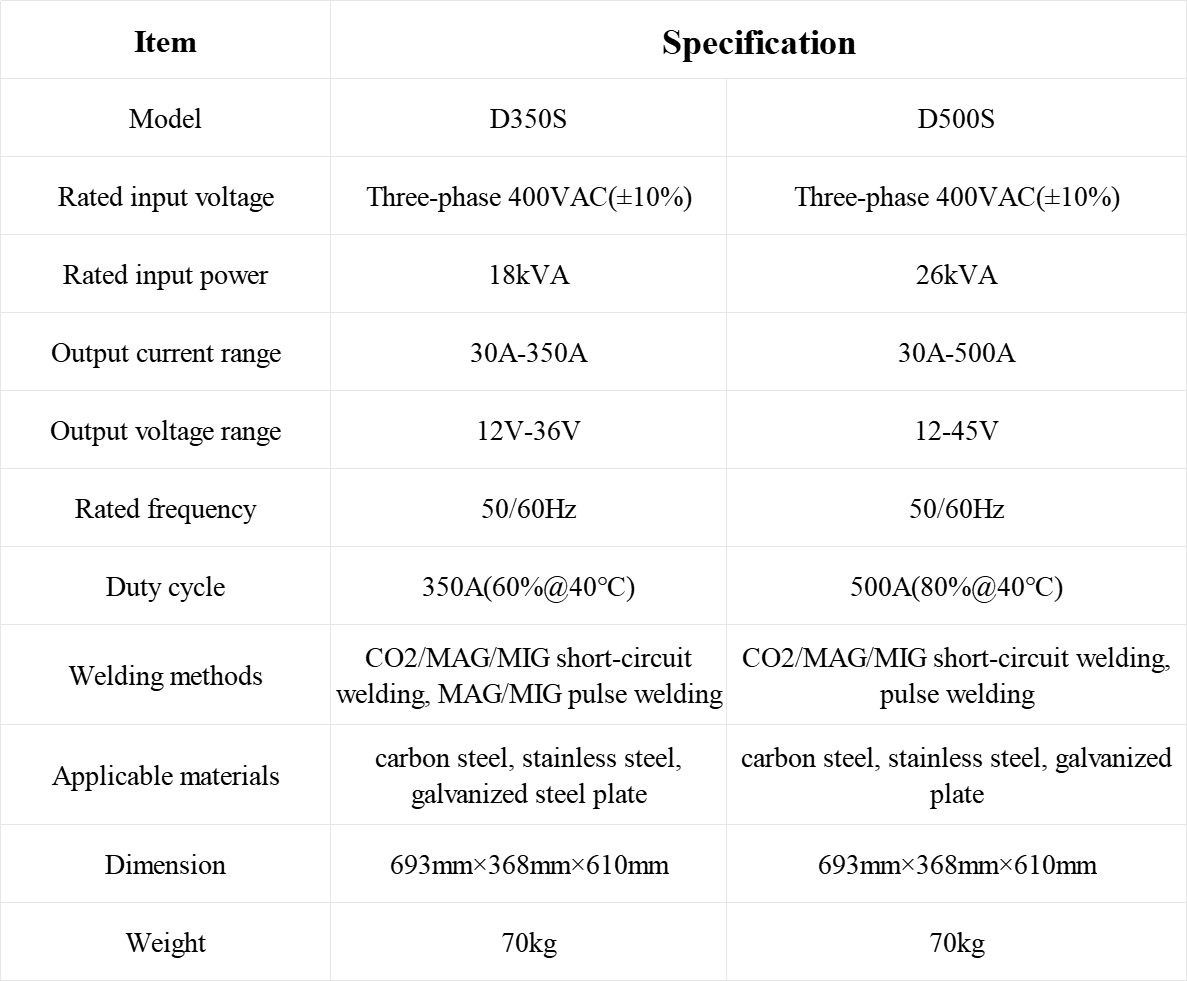

| Item | Specification | Specification |

| Model | D350S | D500S |

| Rated input voltage | Three-phase 400VAC(±10%) | Three-phase 400VAC(±10%) |

| Rated input power | 18kVA | 26kVA |

| Output current range | 30A-350A | 30A-500A |

| Output voltage range | 12V-36V | 12-45V |

| Rated frequency | 50/60Hz | 50/60Hz |

| Duty cycle | 350A(60%@40℃) | 500A(80%@40℃) |

| Welding methods | CO2/MAG/MIG short-circuit welding, MAG/MIG pulse welding | CO2/MAG/MIG short-circuit welding, pulse welding |

| Applicable materials | carbon steel, stainless steel, galvanized steel plate | carbon steel, stainless steel, galvanized plate |

| Dimension | 693mm×368mm×610mm | 693mm×368mm×610mm |

| Weight | 70kg | 70kg |

Automobile Industry

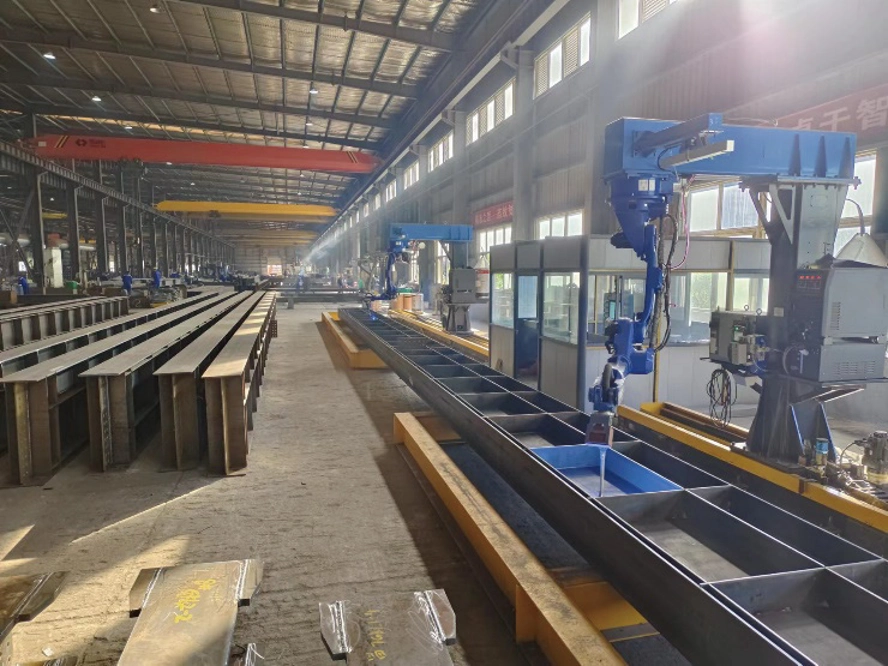

Construction & Steel industry

Electric Power industry

Kitchenware & Home Appliance

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.