About Laser

- Home

- > 3000W Longitudinal Seam Laser Welder

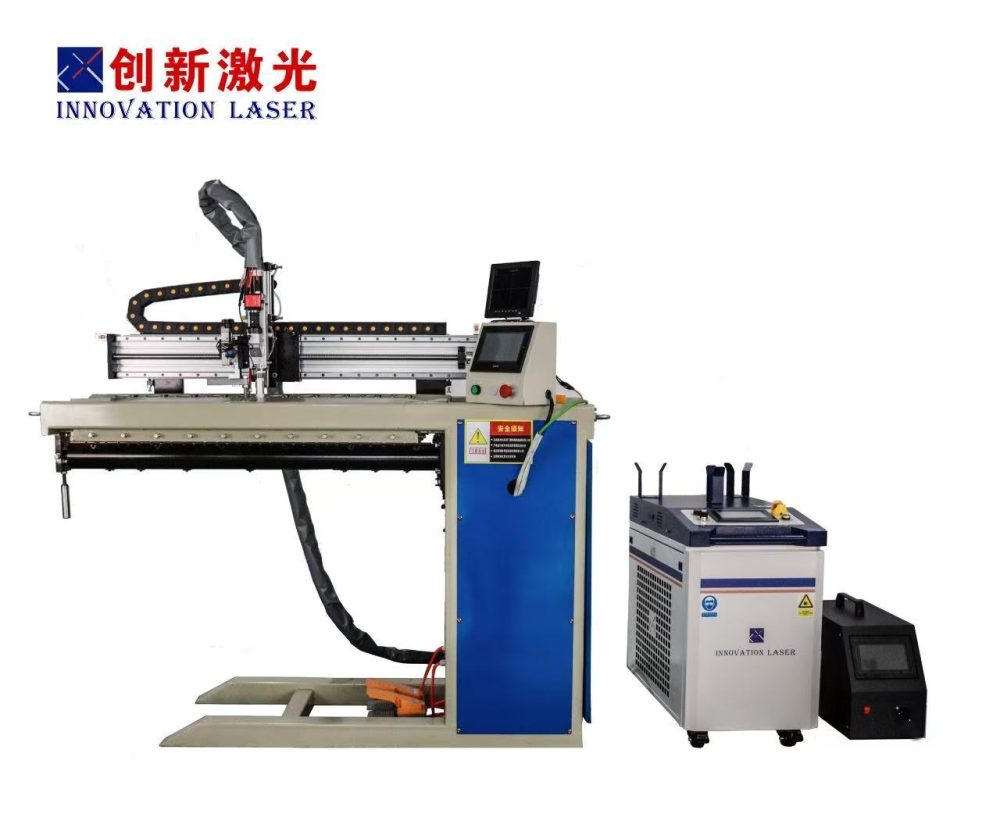

3000W Longitudinal Seam Laser Welding Machine

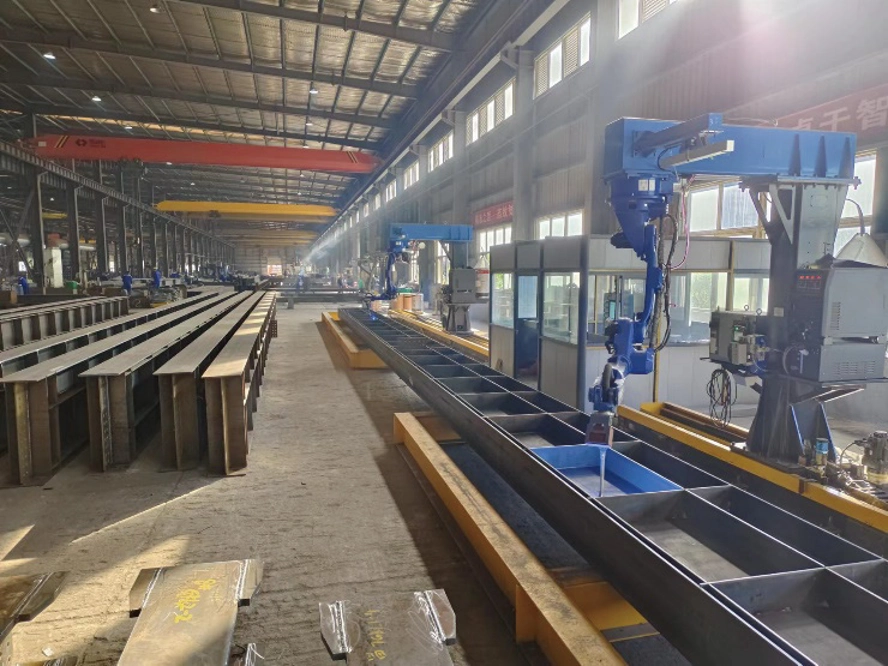

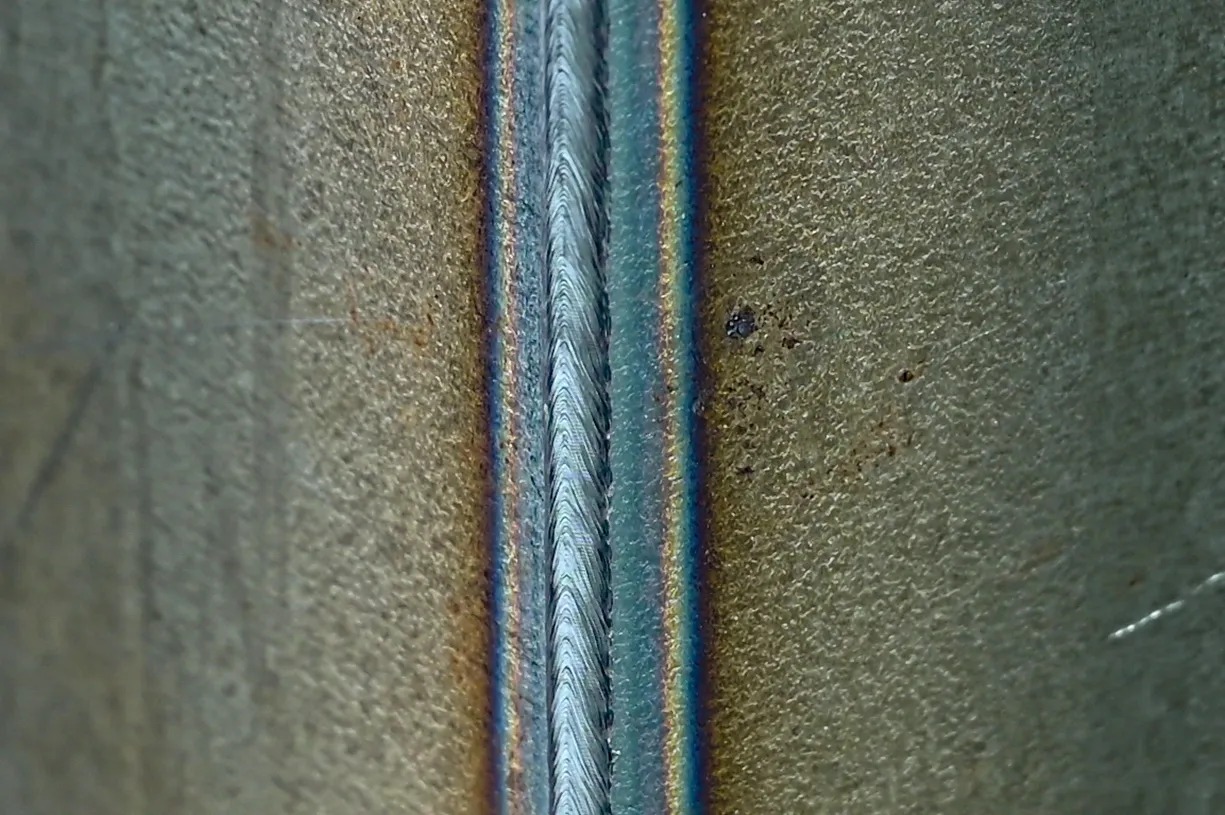

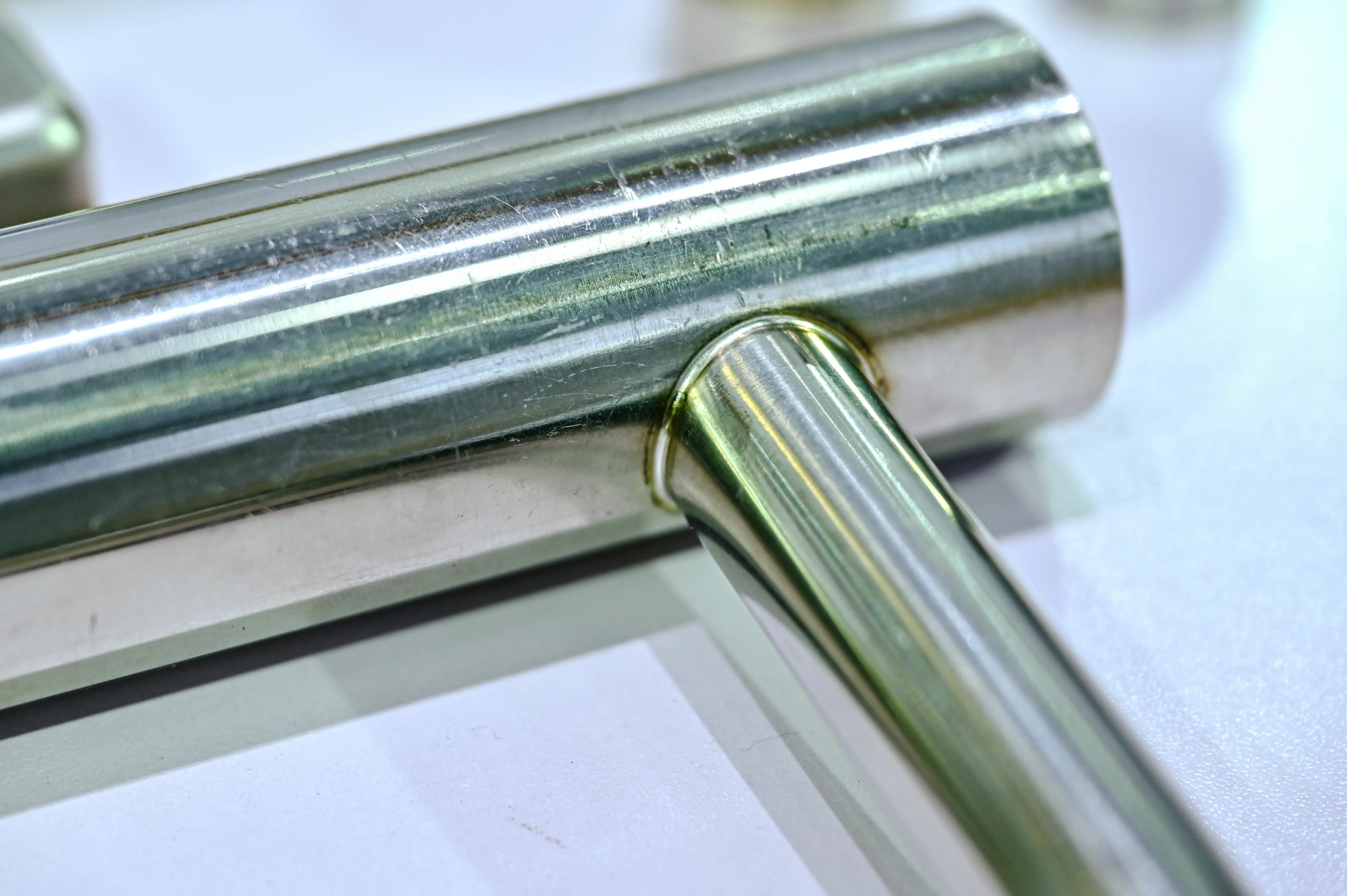

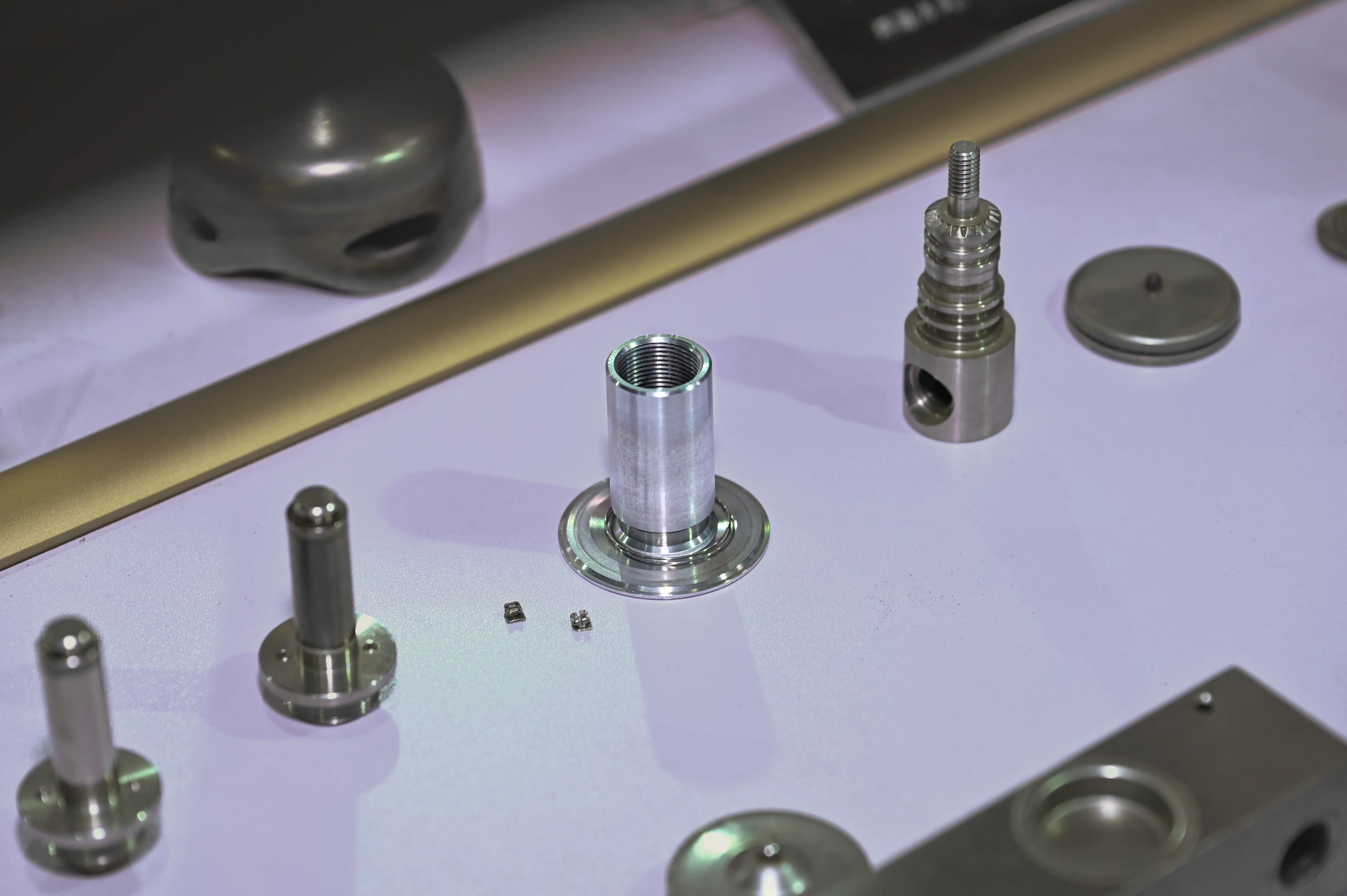

Our 3000W Longitudinal Seam Laser Welding Machine is a specialized equipment for the manufacturing and metalworking industries. It is mainly used for welding cylindrical or tubular structures such as pipes, storage tanks and pressure vessels, enabling continuous straight-line splicing of metal parts along their edges. The welds are strong and consistent, meeting the strict welding quality requirements of industrial production.

Advantages

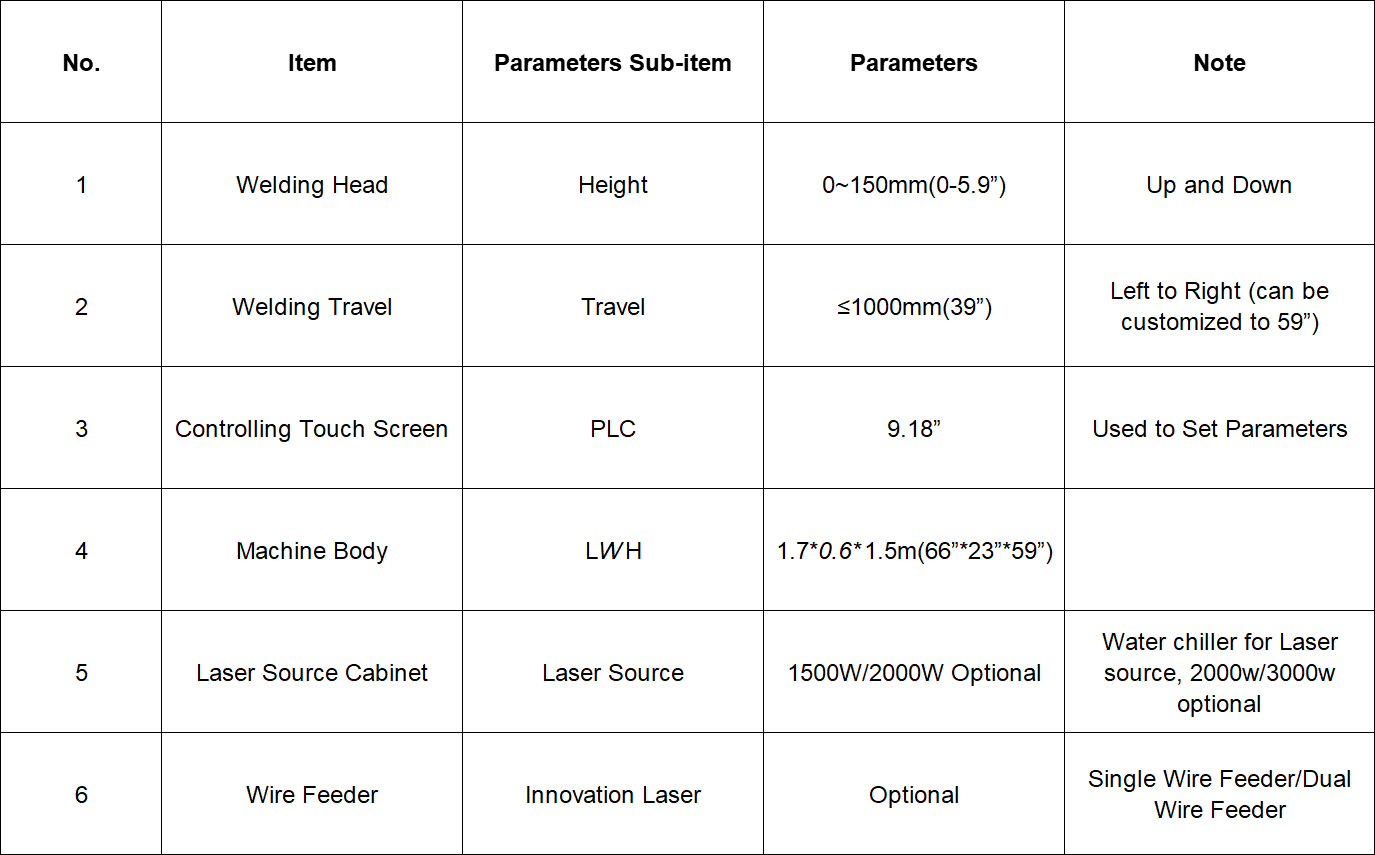

- Superior Quality & Versatility: Strong, consistent welds (0.2-3mm depth) for pipes, pressure vessels, etc.; fits 150-800mm pipe diameters with customizable length/stroke, optional laser sources and wire feeders.

- Efficient & User-Friendly: Max welding speed 2000mm/min for high productivity; 9.18-inch PLC touch screen enables simple parameter setting.

- Precise & Stable: Welding head adjustable up-down (0-150mm) for accurate positioning; robust machine structure ensures consistent performance.

- Reliable Support & Wide Use: Backed by global service network (30+ offices) and professional after-sales team; suitable for aerospace, auto parts, medical equipment, etc.

Automobile Industry

Construction & Steel industry

Electric Power industry

Kitchenware & Home Appliance

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.