About Laser

- Home

- > 3 Axis Flip Positioner

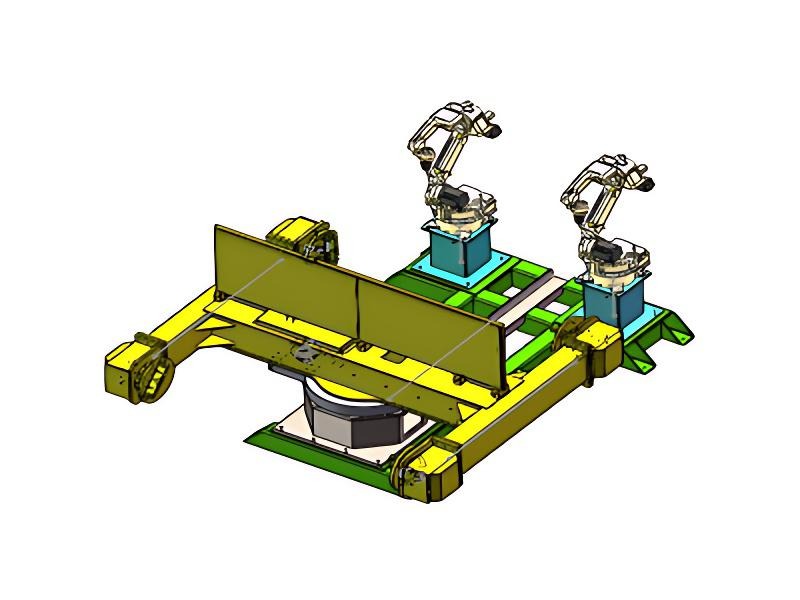

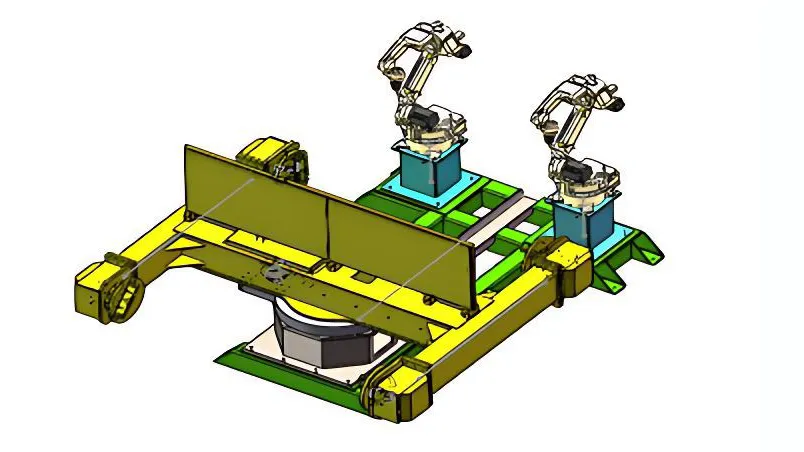

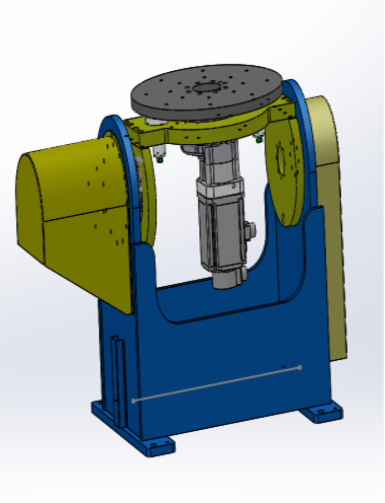

3 Axis Flip Positioner

Customization Options

- Load & Structural Customization

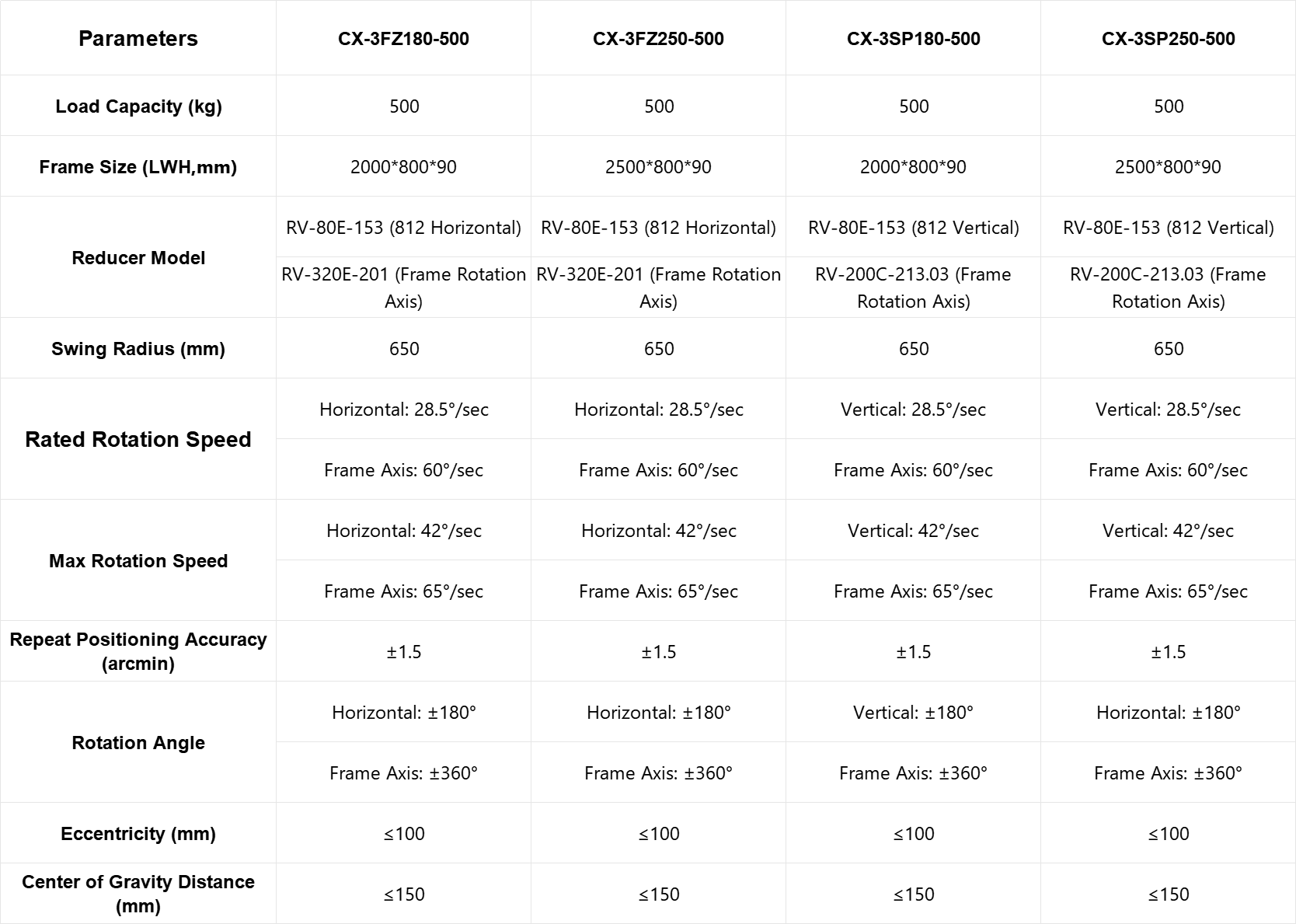

- Load Capacity: Tailored designs for load ranges beyond the standard 500kg (e.g., 800–1500kg) — achieved by reinforcing the 3-axis frame, rotating shafts, and bearing structures, to accommodate heavy workpieces (e.g., large steel structures, aerospace components).

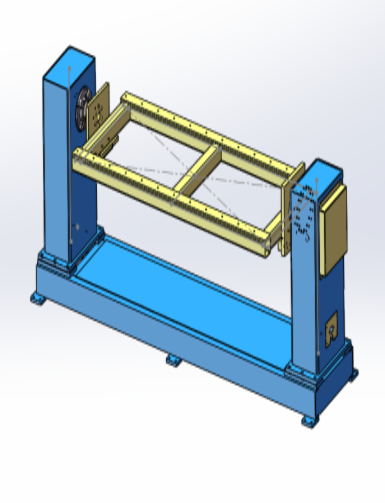

- Frame & Worktable Specifications:

- Custom frame size (LWH) to fit the installation space of production lines or test sites;

- Worktable customization (size, surface treatment: anti-slip coating, positioning holes, threaded mounting points) to match workpiece fixing requirements.

- Swing Radius Adjustment: Expand or reduce the swing radius (beyond 650mm) to adapt to the motion range of large workpieces or compact installation environments.

- 3-Axis Motion Performance Customization

- Rotation Speed & Angle:

- Adjust the rated/max rotation speed of horizontal/vertical/frame axes (e.g., increase the frame axis speed to 80°/sec) to match the rhythm of production or testing processes;

- Expand rotation angles (e.g., extend horizontal axis rotation to ±270°) for scenarios requiring larger motion postures.

- Positioning Accuracy: Upgrade to higher precision (e.g., ±1.0 arcmin or better) by optimizing transmission components (e.g., high-precision reducers) and adding closed-loop feedback sensors, suitable for precision assembly or testing scenarios.

- Rotation Speed & Angle:

- Configuration & Accessory Customization

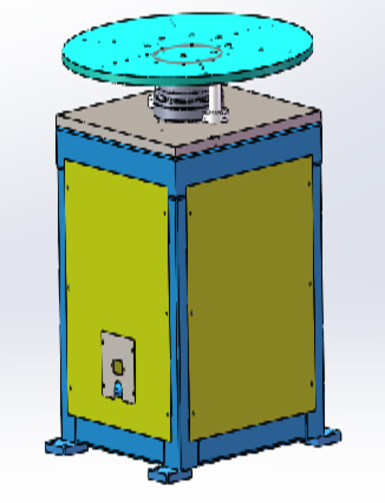

- Reducer & Drive System:

- Alternative reducer models (e.g., higher torque, higher precision specifications) to match motion stability requirements;

- Compatibility with specific servo drive systems (e.g., matching the customer’s existing PLC/robot controller) for seamless integration into production lines.

- Functional Accessories:

- Sensors: Add angle feedback sensors, overload protection sensors, or position limit sensors;

- Safety Components: Equip emergency stop devices, protective enclosures, or interlock systems to enhance operational safety;

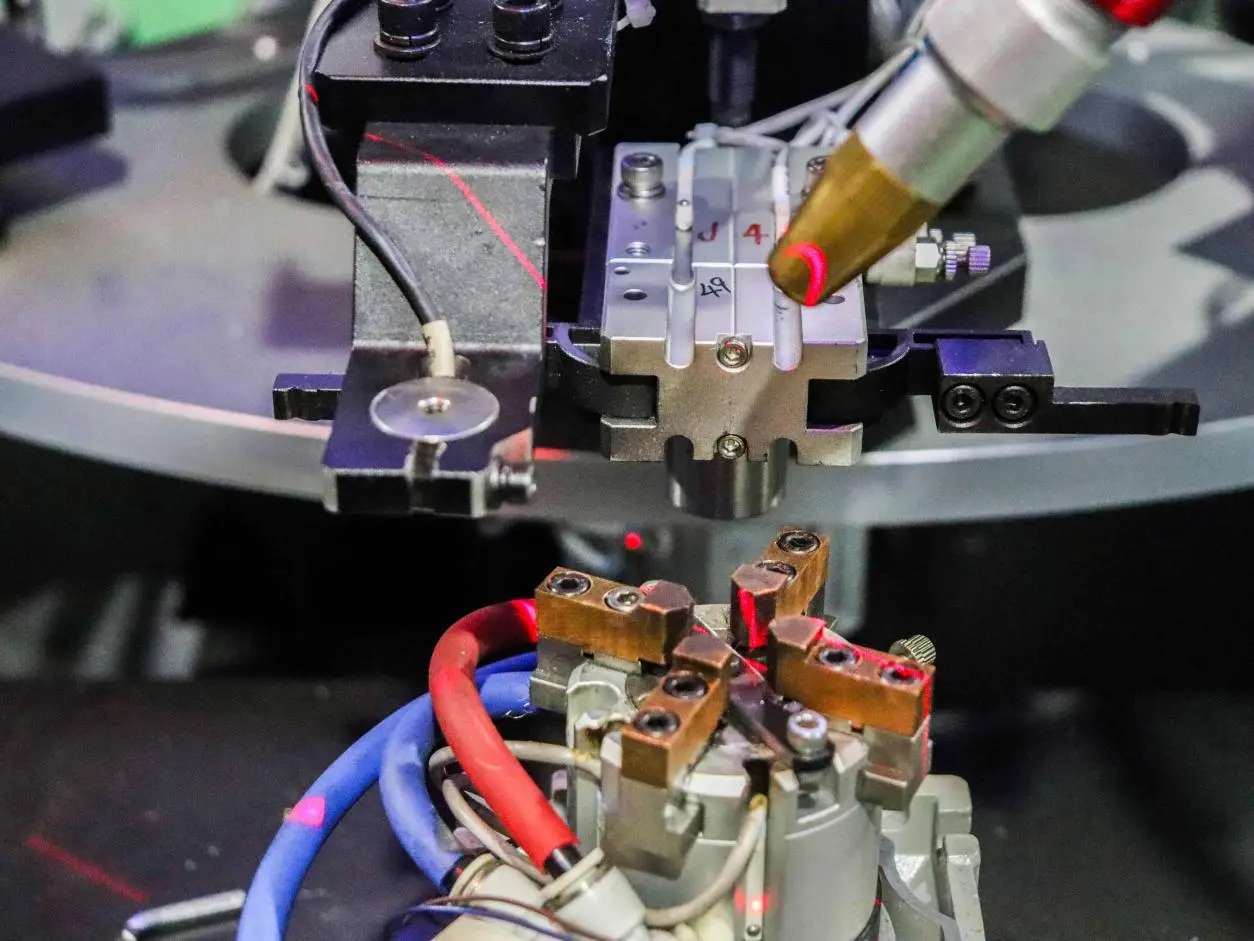

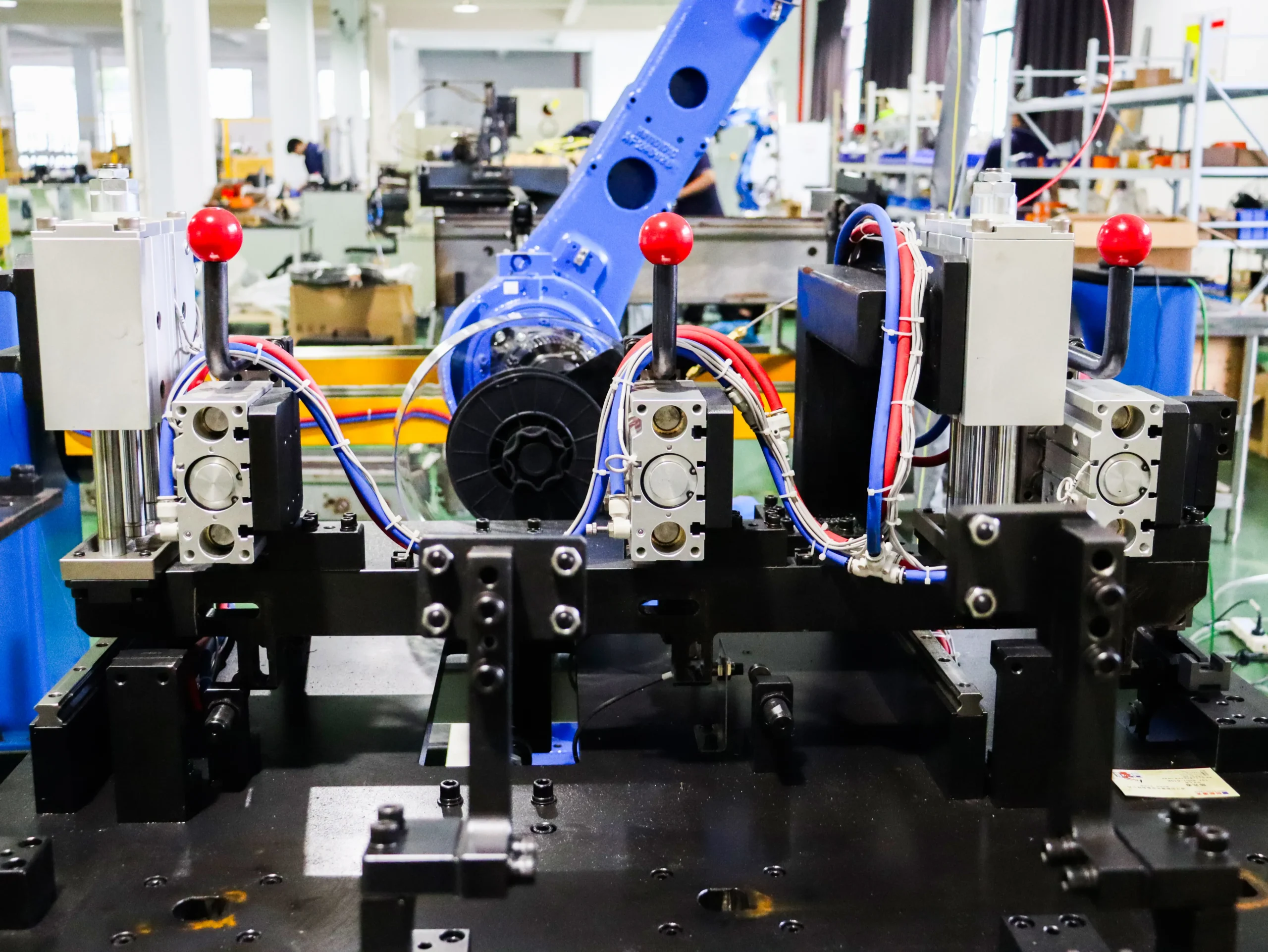

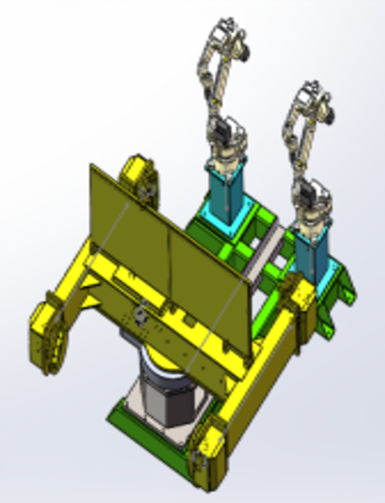

- Robot Matching: Customize interface dimensions and connection methods to match specific brands/models of collaborative robots (as shown in the product image).

- Reducer & Drive System:

- Environmental Adaptation Customization

- Special Environment Modifications:

- Dust/Waterproof: Custom sealed enclosures (IP65 or higher) for dusty, wet, or spray-based production scenarios (e.g., coating lines);

- Temperature Resistance: Adopt heat-resistant materials/cooling systems for high-temperature environments (e.g., heat treatment matching), or low-temperature lubricants for cold-storage application;

- Corrosion Resistance: Apply anti-corrosion coatings to the frame and worktable for scenarios involving chemical processing or marine environments.

- Special Environment Modifications:

Application Cases

Automotive industry

Arc welding steel structure

Charging cabinet

Kitchenware industry

- Heavy-Duty Welding Production

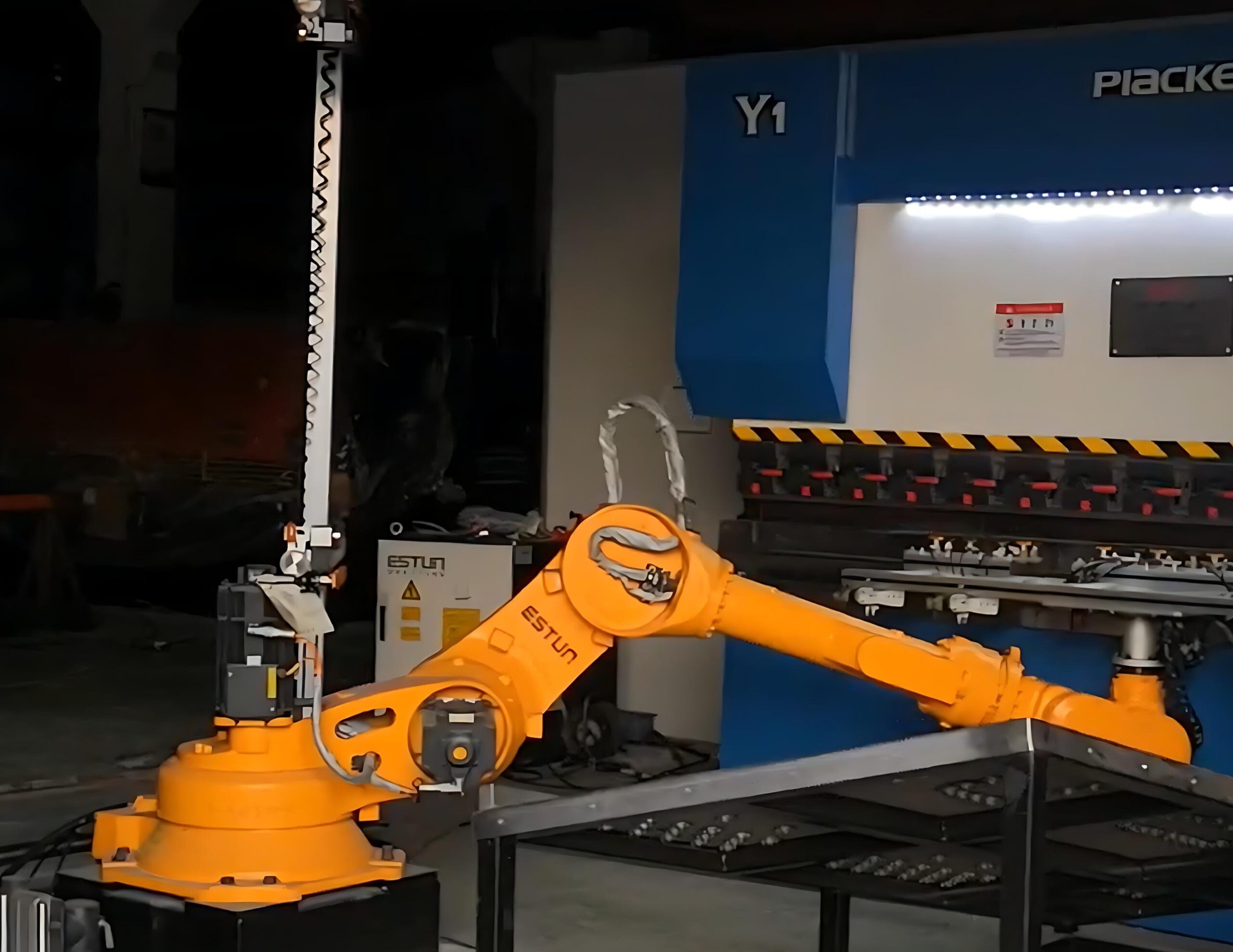

Matched with welding robots (as shown in the product image): the 3-axis flip function positions large workpieces (e.g., steel structures, mechanical frames) at multi-angle welding postures, enabling robots to complete full-position welding (flat/vertical/overhead) and ensuring uniform weld quality.

- Aerospace Component Testing

Simulates complex motion postures of aerospace parts (e.g., engine components, cabin segments) via 3-axis rotation, verifying structural stability and fatigue resistance under multi-directional flip/rotation conditions.

- Precision Equipment Assembly

Used in assembling complex equipment (e.g., industrial robots, medical imaging devices): the 3-axis positioning function adjusts the angle of precision components (e.g., mechanical arms, sensor modules) to achieve accurate multi-directional fitting.

- Multi-Angle Coating & Surface Processing

Rotates workpieces (e.g., large metal plates, composite material parts) via 3-axis flip, ensuring uniform coverage of coatings, sandblasting, or polishing on all surfaces, avoiding processing dead angles.

- Automated Logistics & Handling

Integrated into intelligent logistics lines: the 3-axis flip function adjusts the posture of heavy cargo (e.g., large containers, industrial packages) for loading/unloading, sorting, or stacking, improving handling efficiency.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.