About Laser

- Home

- > What Factors Determine the Penetration Depth in Laser Welding?

Laser Welding: Controllable Penetration & Max Efficiency

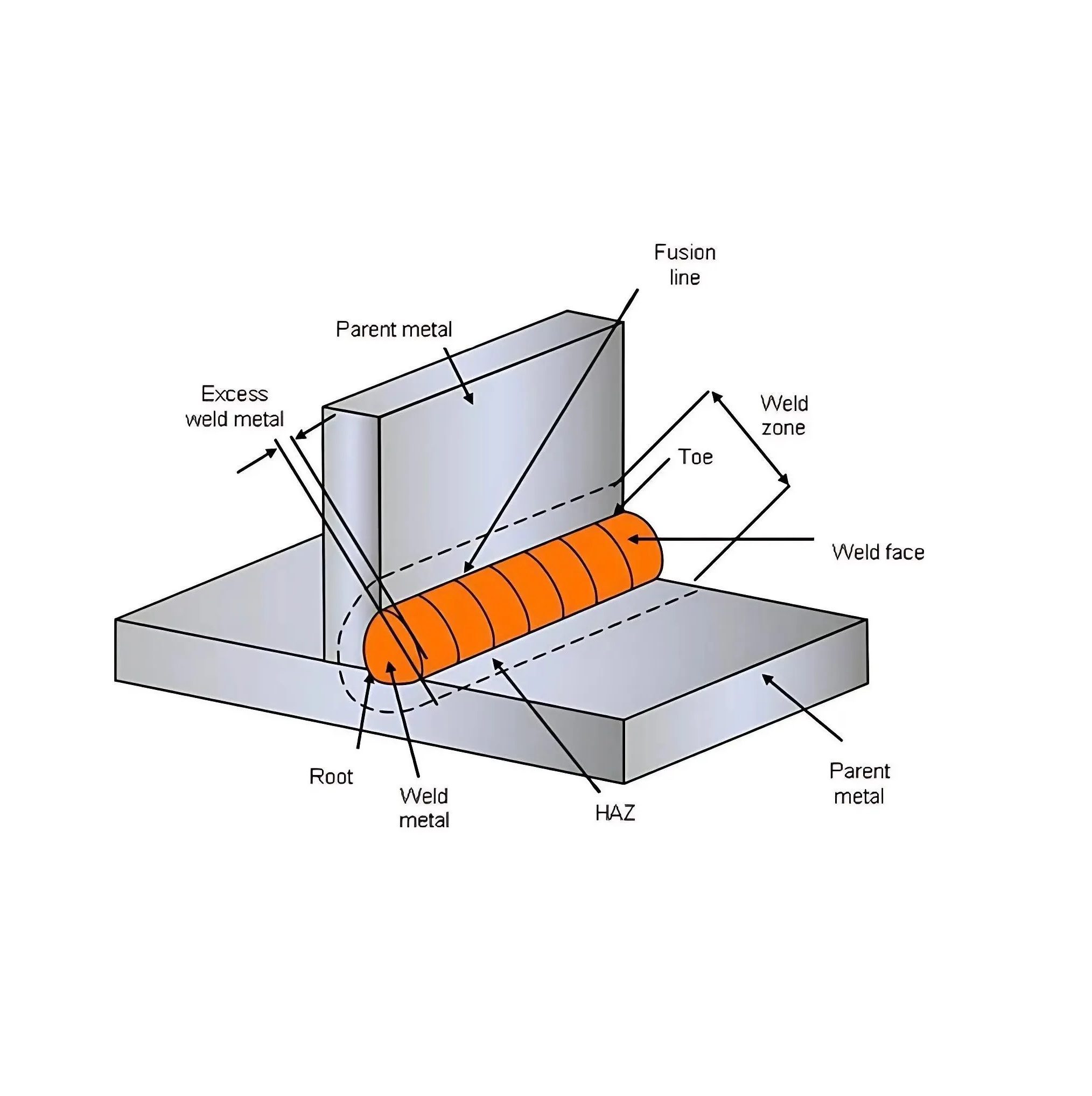

Basic Principle : Energy Density

The essence of laser welding is to irradiate the material with a beam of extremely high energy density, causing it to melt or even vaporize. The energy input is often measured as Line Energy:

Line Energy (J/mm)= Laser Power (W)/ Welding Speed (mm/s)

From this formula, we can see:When the welding speed remains constant, increasing the laserpower directly increases the line energy applied to the workpiece

More energy is input into the material, enabling it to melt more metal, resulting in greater penetration

Laser welding features it deeper penetration compared with other welding methods

Below, we will conduct a metallographic analysis of the welding effects of lasers with differentlaser power;

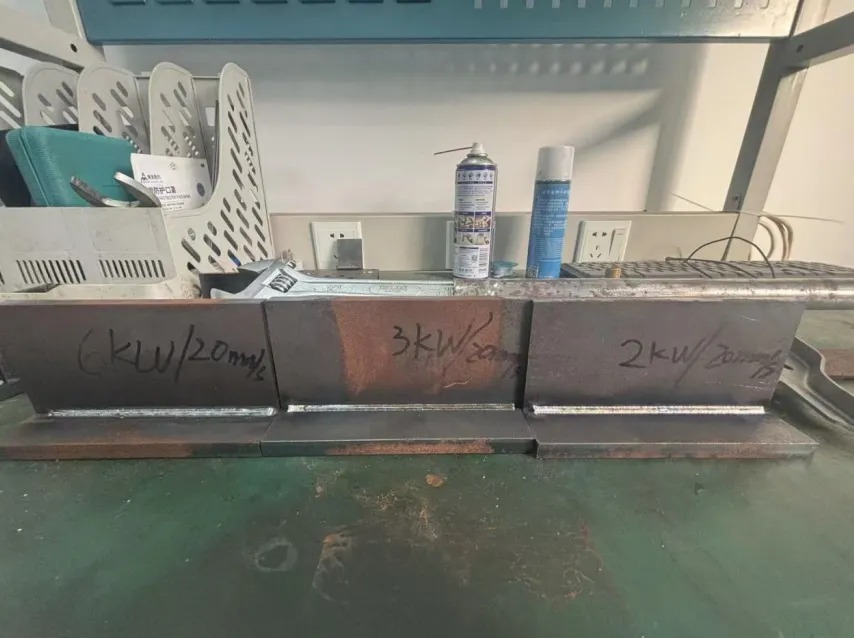

1.1 Material: Carbon Steel 1.2 Thickness:10mm

The laser welding appearance under 2kw/3kw/6kw

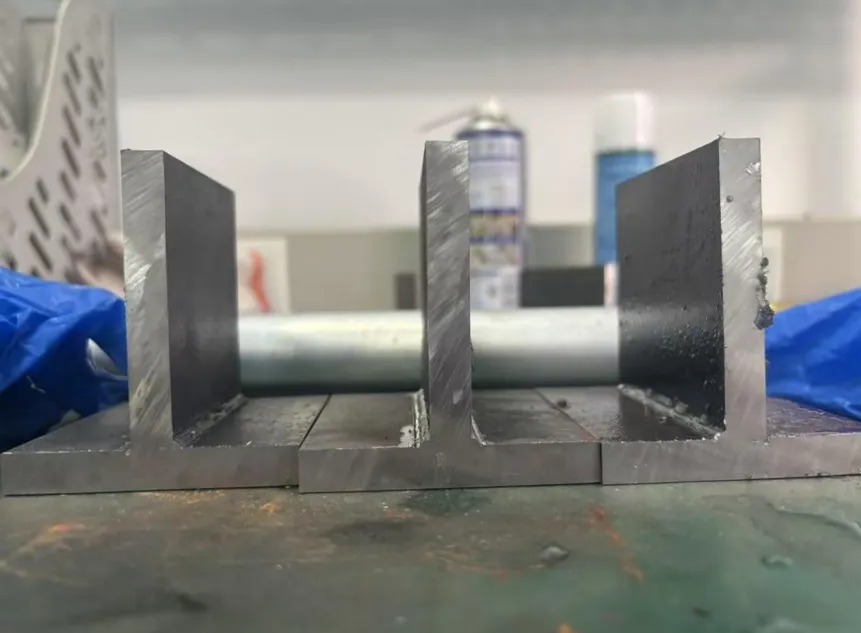

Cross-section after cutting (from left to right:6kw-3kw-2kw)

2.1 2kw laser welding with wire speed 20mm/s

The 2kw weld has a very small penetration depth, there are approx. 0.5mm on each side

2.2 3kw laser welding with wire speed 20mm/s

The 3kw weld also has a very small penetration depth,there are approx. 0.8mm on each side

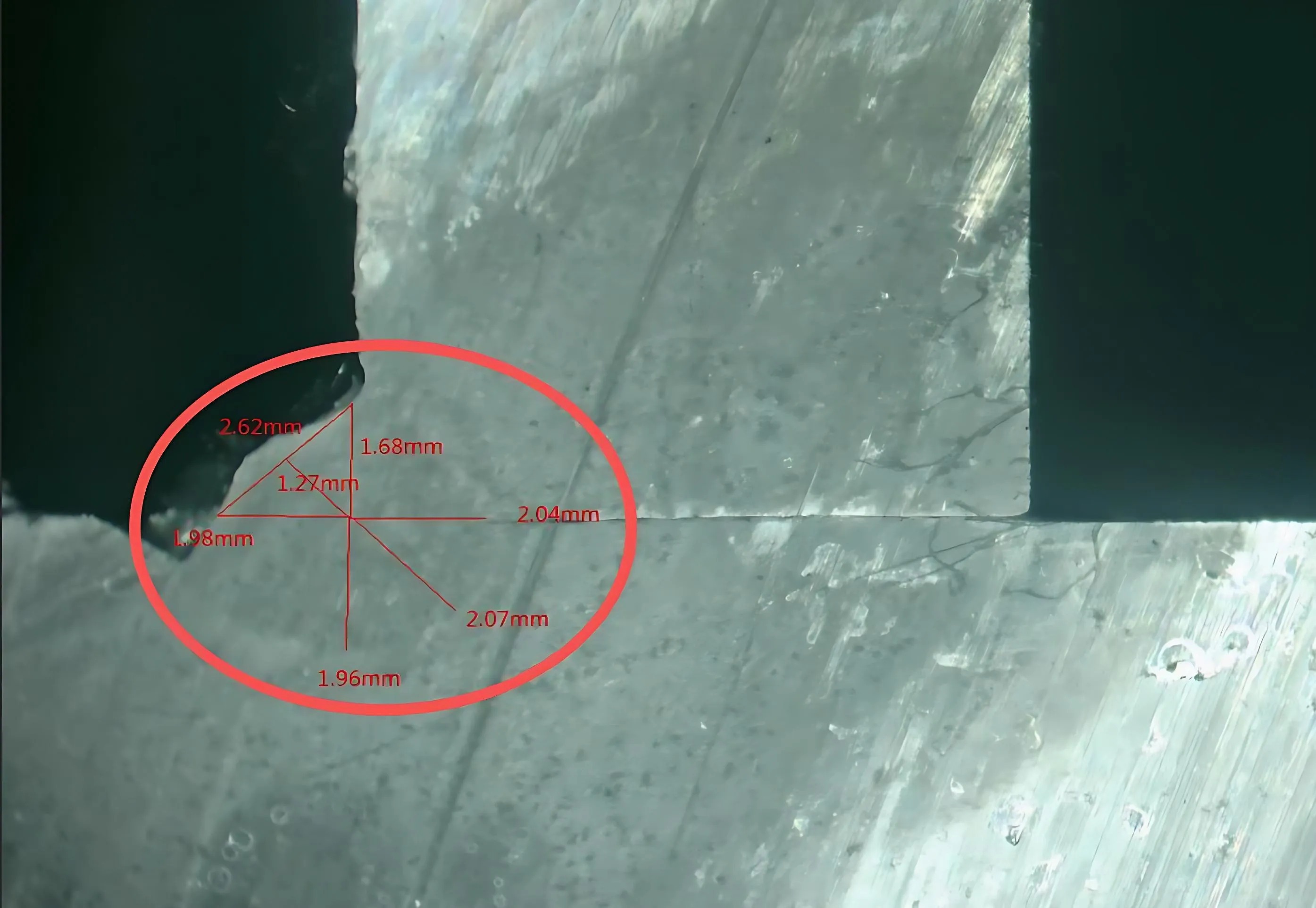

2.3 6kw laser welding with wire speed 20mm/s

It can be seen that the 6kw weld has a penetration depth of at least 2mm; the greater the penetration depth, the stronger the weld.The weld is beautiful and full.

The effect of speed on welding quality

3.1 6kw laser welding with wire speed 35mm/s

3.2 6kw laser welding with wire speed 50mm/s

As the welding speed increases, the penetration depth decreases, and welding quality problems such as more spatters and undercut occur.

Conclusion:

1. The above data are based on laser welding tests with wire feeding. If self-fusion welding(without wire feeding) is used, the penetration depth will be greater than the above data.

2. Currently, most applications of lasers are in thin metal plates. As you can see, a 2kW laser can weld a 10mm metal plate also, but it doesn’t penetrate deeply enough and isn’t very strong. We recommend 2kW with a welding thickness not exceeding 3-4mm. 3kW with a welding thickness not exceeding 5-6mm. 6kW with a welding thickness not exceeding 8mm.

3. Laser welding speeds can reach 100mm/s or more, but these are only suitable for in-line welding. For general welding, especially wire-feeding laser welding, we recommend 20mm/s-30mm/s.

4. The above data is our conservative estimate as the laser equipment supplier. If the customer has any requirements regarding air leakage test, water leakage test, pressure testing, or other test for the product, the customer’s reuirements shall prevail.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.