About Laser

- Home

- > Laser Welding

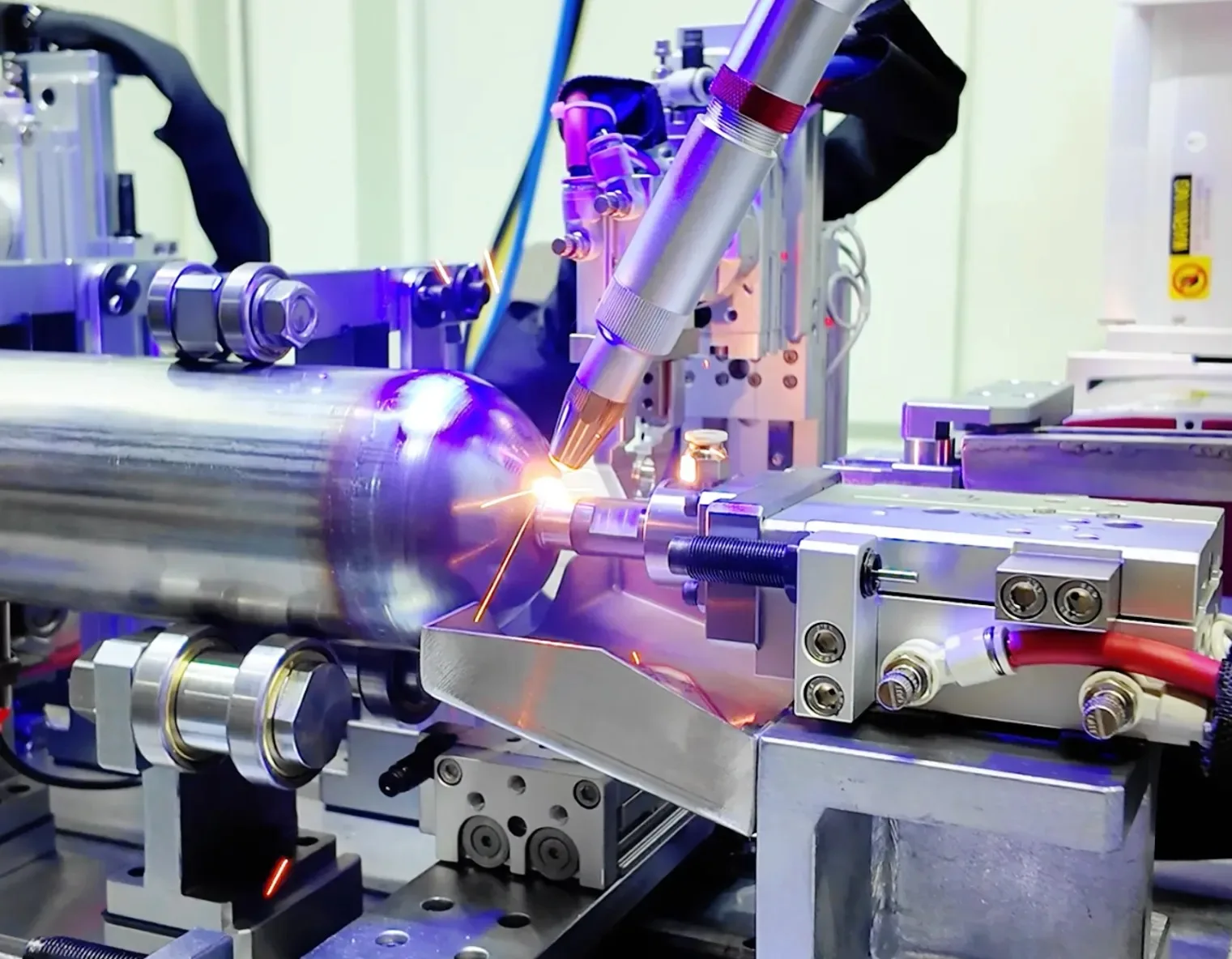

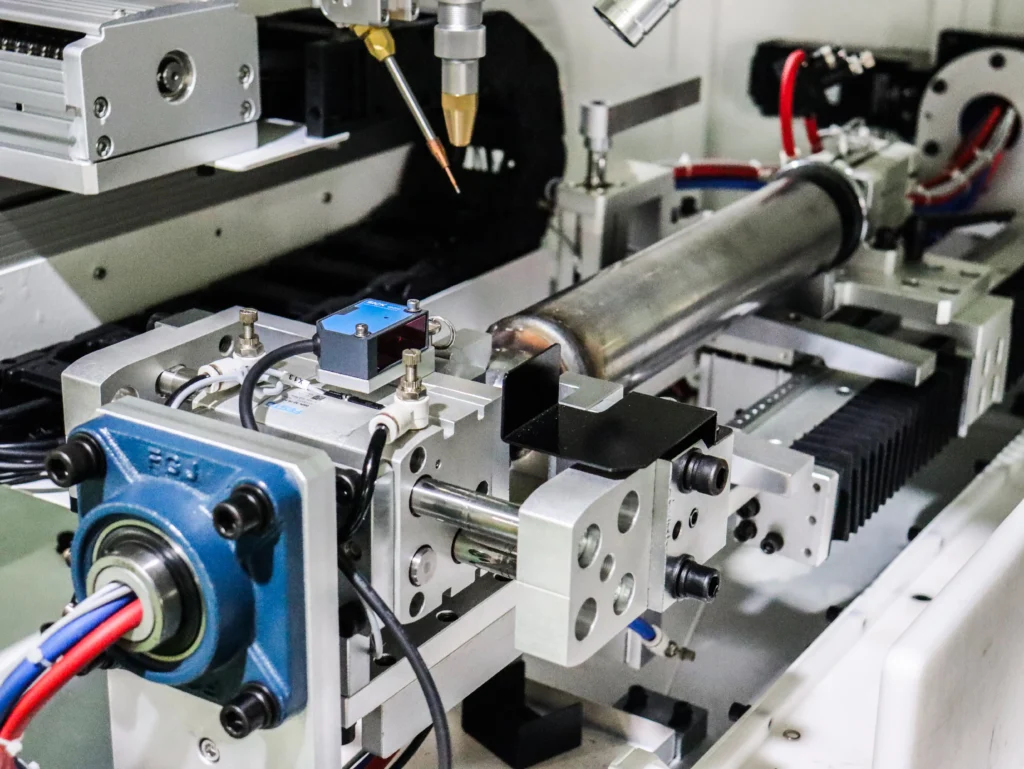

3D Robotic Welding

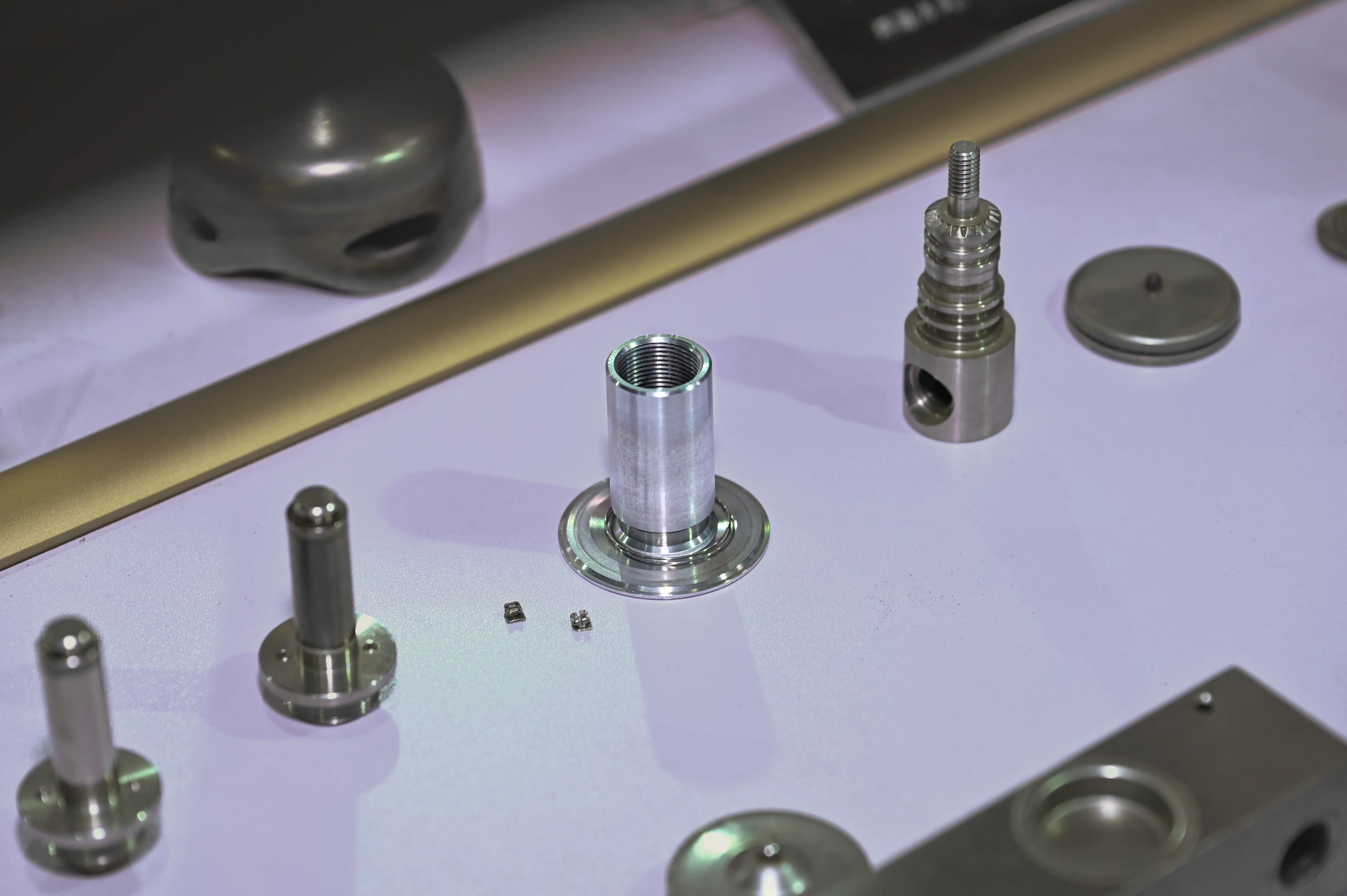

High precision, minimal heat distortion, fast speed, non-contact process, versatile material compatibility.

Key Considerations for Laser Welding Robots

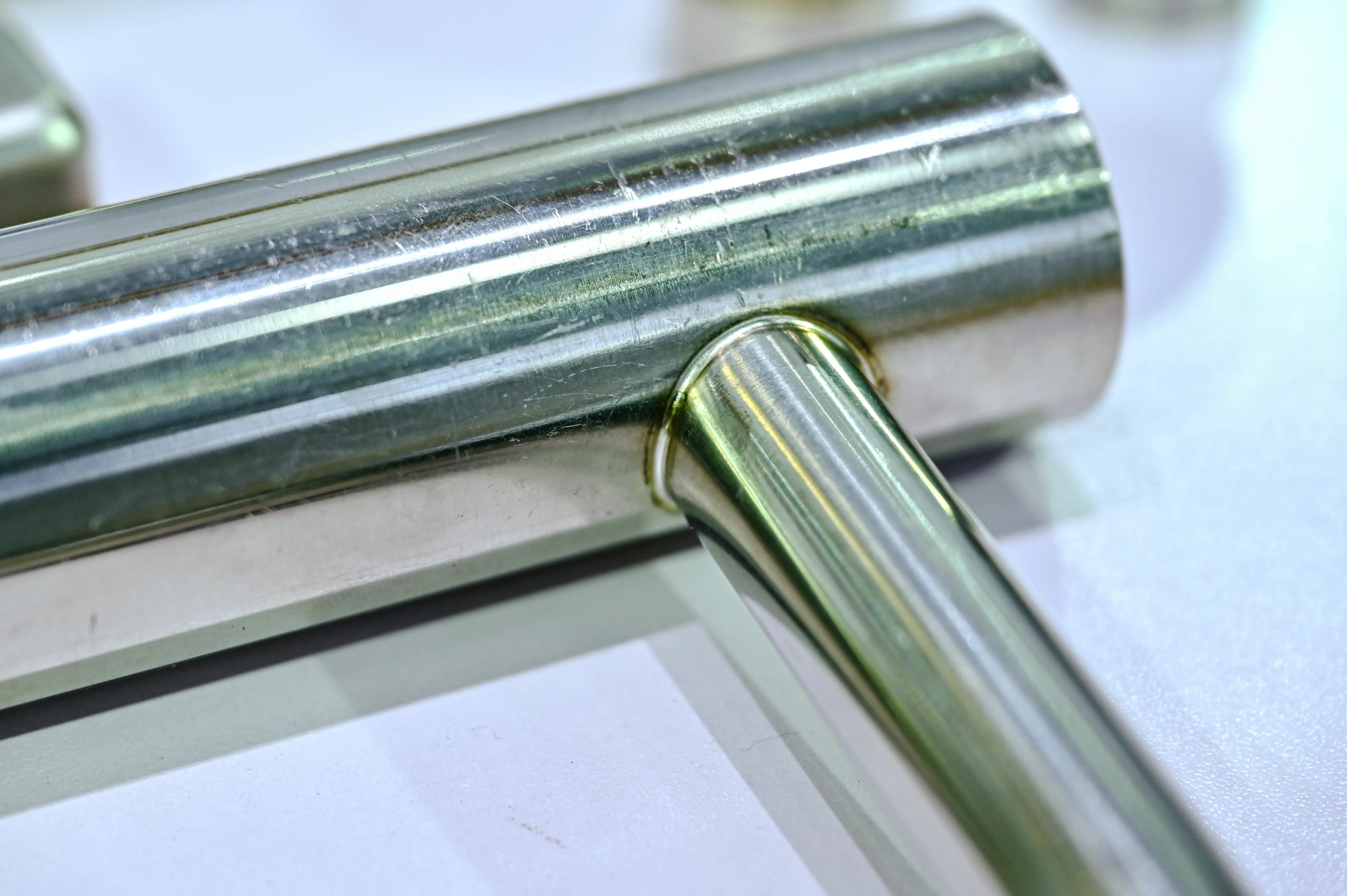

1. The Good Fits-up: Demands on Prior Processes

Laser welding is often the last critical step—like assembling a watch case. If part dimensions are inaccurate, even the finest laser cannot create a perfect seam.

Example: Welding two enclosures with misaligned edges due to imprecise bending is like trying to zip up a jacket with misaligned teeth—the beam may miss the joint entirely.

Requirement: Part fit-up accuracy typically must be under 0.2 mm—demanding near perfect cutting, bending, or stamping beforehand.

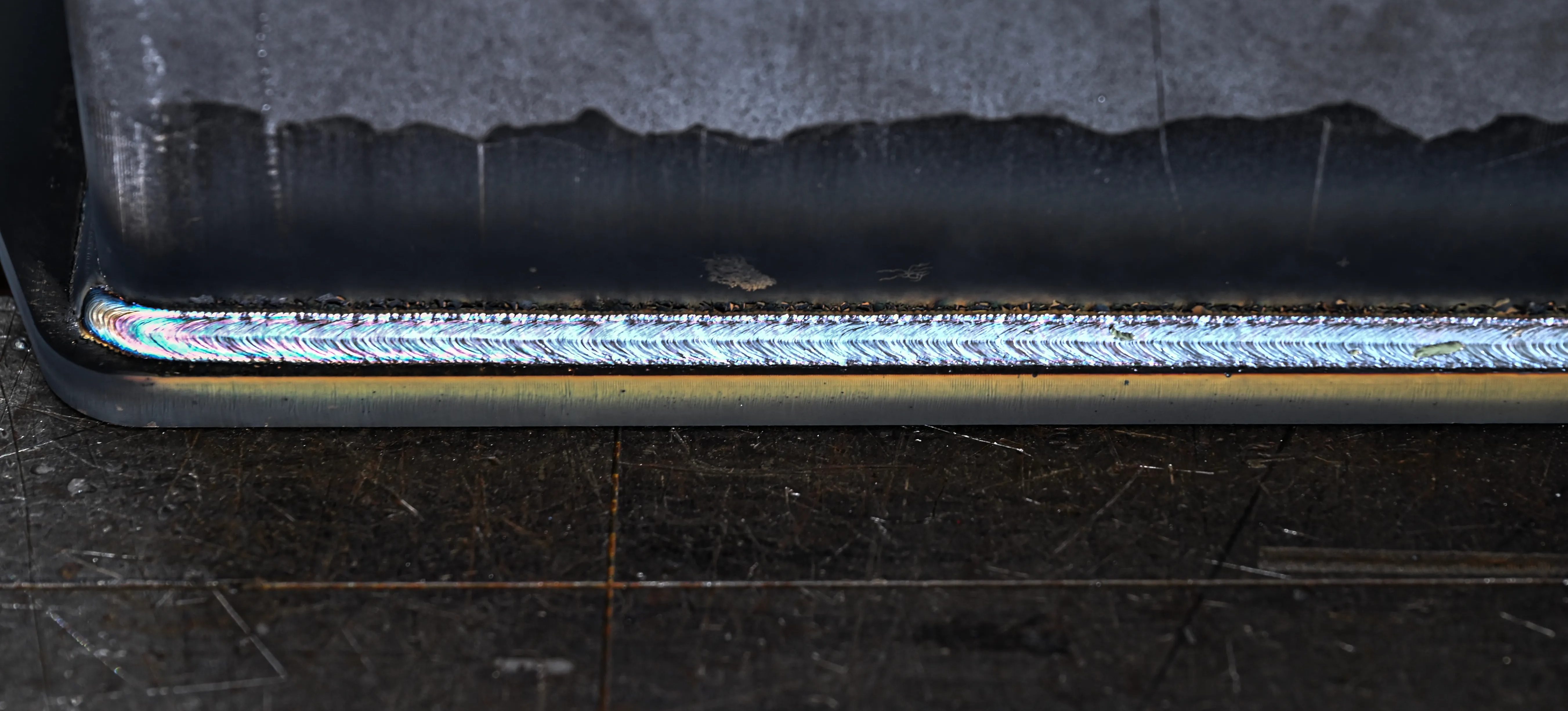

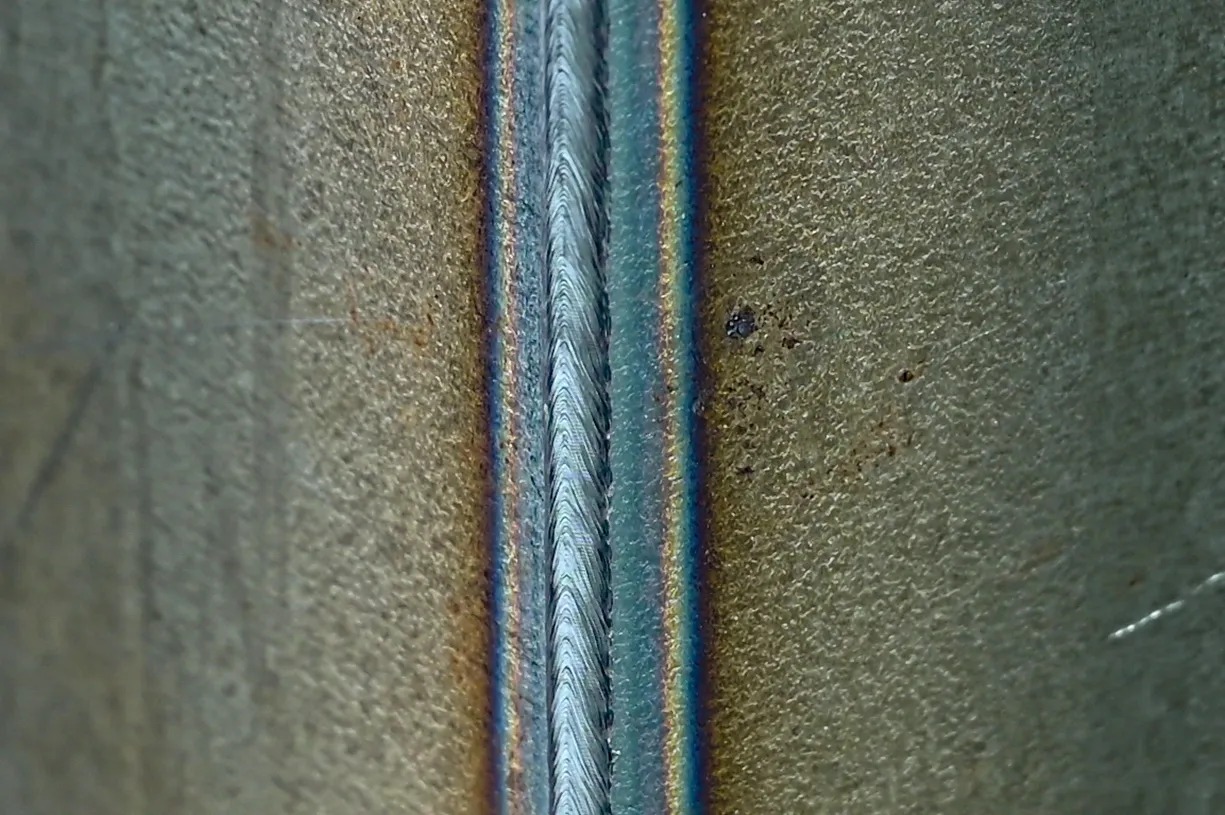

2. The Core "Light Needle" vs. Gap Dilemma

The laser beam is an extremely fine “light needle,” excelling at fusing tightly mated joints. For autogenous welding, the gap is recommended under 0.2 mm. For wire-fed welding, gap tolerance is slightly higher but strictly governed:

Thick plate (>1mm): Gap should ideally be ≤ half the plate thickness.

Thin plate (<1mm): The smaller the gap, the better; otherwise, high-power wire filling easily causes burn-through.

General Limit: Wire diameter and weld bead width typically should not exceed 1.6 mm.

3. Jigs and Fixtures

Increased surface roughness: Insufficient precision can cause the laser focus position to shift, leading to uneven energy distribution and resulting in burrs and slag on the cut surface.

4. “High Repeatability”-- Robotic Accuracy

The robot must possess high repeatability, typically within ±0.02mm, ensuring each welding path is perfectly replicated. This enables zero-defect consistency in high-volume production.

We use top robots (Yaskawa, ABB, FANUC) to achieve micron-level precision, ensuring consistent, high-quality welds

Conclusion:

Truesyn has established itself as a trusted partner for numerous clients by delivering high-performance laser welding and cutting robotic solutions. We specialize in designing and implementing tailored automation systems that enhance precision, boost productivity, and ensure superior quality. Our expertise integrates advanced robotics with industry-leading laser technology, providing reliable, future-proof solutions that drive efficiency and competitiveness for our customers worldwide.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.