About Laser

- Home

- > Laser Clean

advantage

Laser Cleaning

Laser cleaning is a precise, non-contact method that replaces damaging and polluting techniques like sandblasting and chemical cleaning. It improves product quality and extends lifespan in manufacturing, heritage conservation, and aerospace. This guide covers its principles, advantages, applications, and speed considerations for informed adoption.

Innovationlaser@zjcxlaser.com

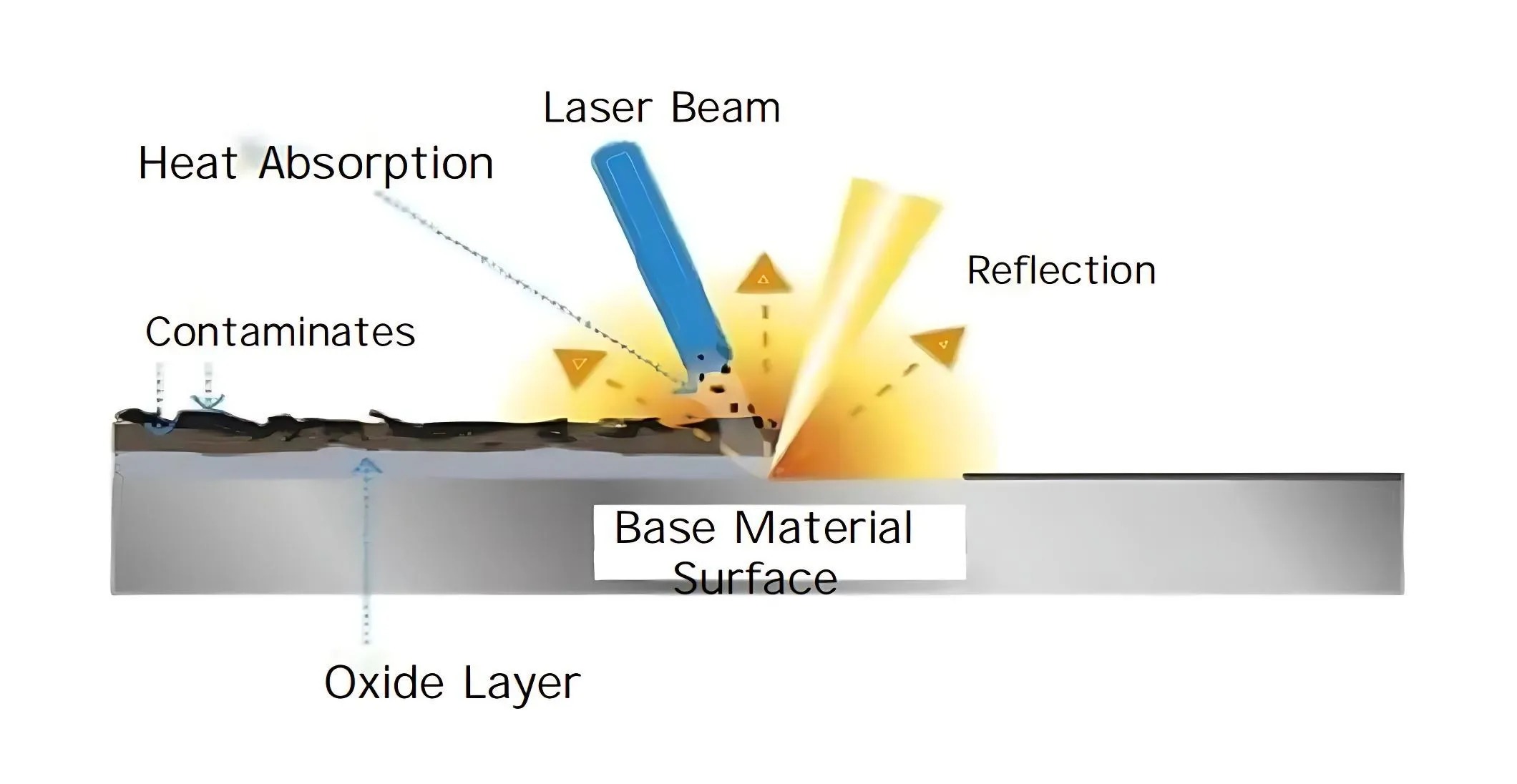

1. How Laser Cleaning Works ?

Laser cleaning uses targeted laser energy to remove unwanted substances (rust, oil, coatings, etc.) from surfaces—without touching the base material. The key lies in the difference in “energy sensitivity” between contaminants and the substrate: contaminants (like rust or paint) absorb laser energy easily, vaporizing or peeling off quickly. The base material (such as steel or aluminum) is barely affected when laser parameters are properly set.

To clean efficiently, the laser beam scans the surface rapidly, covering large areas while maintaining precision. Critical parameters (wavelength, power, scanning speed) are adjusted based on the contaminant type and substrate—ensuring only unwanted layers are removed, no damage to the workpiece.

2. Key Advantages Over Traditional Methods

aser cleaning outperforms conventional techniques in practicality and value:

- Non-contact & Damage-Free: No physical contact or abrasive materials, avoiding scratches/wear on delicate or precision parts (unlike sandblasting or high-pressure water).

- Precise & Targeted: The laser focuses only on the cleaning area, even for small or complex structures—no need for masking or extra shielding (unlike chemical cleaning).

- Eco-Friendly & Safe: No toxic chemicals, abrasive waste, or excessive noise. Only small amounts of dust/fumes are produced, easily collected with simple exhaust systems.

- Easy to Use & Automate: Simple operation, easy installation, and seamless integration with robots/production lines—ideal for mass production or repetitive tasks.

- Cost-Effective Long-Term: Low operating costs (only electricity, no consumables like sand or chemicals) and minimal maintenance, offsetting the initial investment.

3. Practical Applications

Common Uses

- Remove rust, oil, dust, paint, coatings, oxide layers, and stains from metal/non-metal surfaces.

- Prepare surfaces for welding, bonding, or painting (improves adhesion and product lifespan).

- Clean molds (remove residues, extend mold life) and medical equipment (sanitize to meet hygiene standards).

- Gently clean cultural relics (bronze, stone, textiles) without irreversible damage.

Key Industries

- Manufacturing (auto, electronics, machinery): Component cleaning and surface preparation.

- Aerospace: Clean engine parts and fuselage components without damaging high-strength materials.

- Medical & Food Processing: Sanitize equipment to meet strict safety standards.

- Cultural Heritage Preservation: Delicate artifact cleaning and restoration.

4. Analysis of Laser Cleaning Speed and Influencing Factors

Speed is a key consideration for industrial use—laser cleaning balances efficiency and quality:

Basic Speed

Under standard conditions (medium contamination like thin rust or oil), laser cleaning speeds range from 0.5–5 square meters per hour. For optimal setups, it can clean even faster, meeting mass production needs.

Key Factors

- Laser Power: Higher power = faster cleaning (especially for thin contaminants).

- Contaminant Thickness: Thin layers (oil, light rust) clean quickly; thick deposits (heavy rust, thick paint) may require multiple scans.

- Workpiece Shape: Flat surfaces clean faster than curved or porous parts.

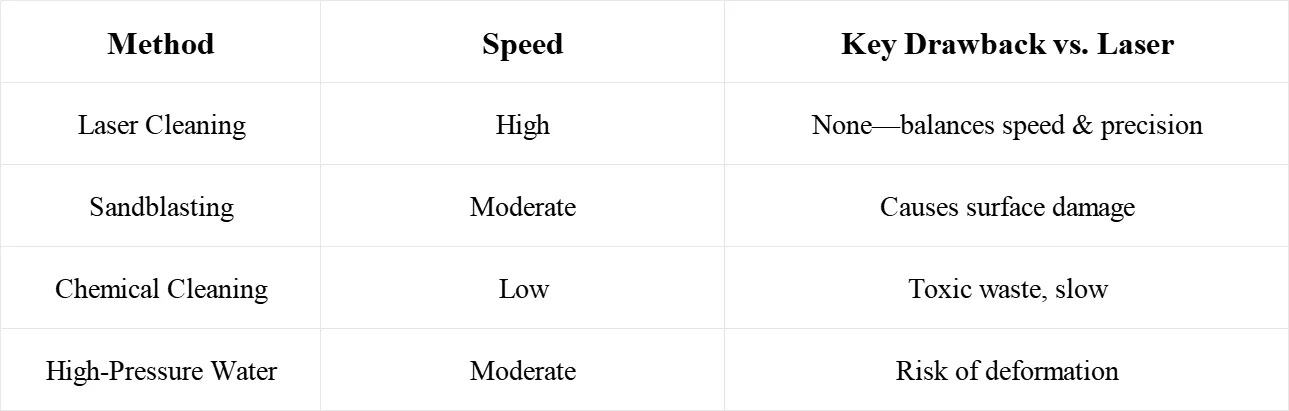

Quick Comparison to Traditional Methods

Conclusion:

Boasting clear working principles, laser cleaning outperforms traditional methods in damage control, precision, and environmental friendliness. It is well-suited for high-demand scenarios, with speed meeting large-scale application needs. As costs decrease and technology advances, it will become the cornerstone of green precision cleaning across more industries.

01

Step

Submit Requirements

Provide drawings, photos, videos, and basic project details to help us quickly understand your needs.

02

Step

Technical Evaluation

Our team analyzes your materials and proposes the most suitable laser or automation solution.

03

Step

Design & Production

We finalize the solution, start detailed design, and manufacture the required equipment.

04

Step

Delivery & Support

We install the system, train your team, and provide ongoing technical service.

Contact

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.