About Laser

- Home

- > Innovative laser: Oven Laser welding solution

TrueSyn laser oven welding solution

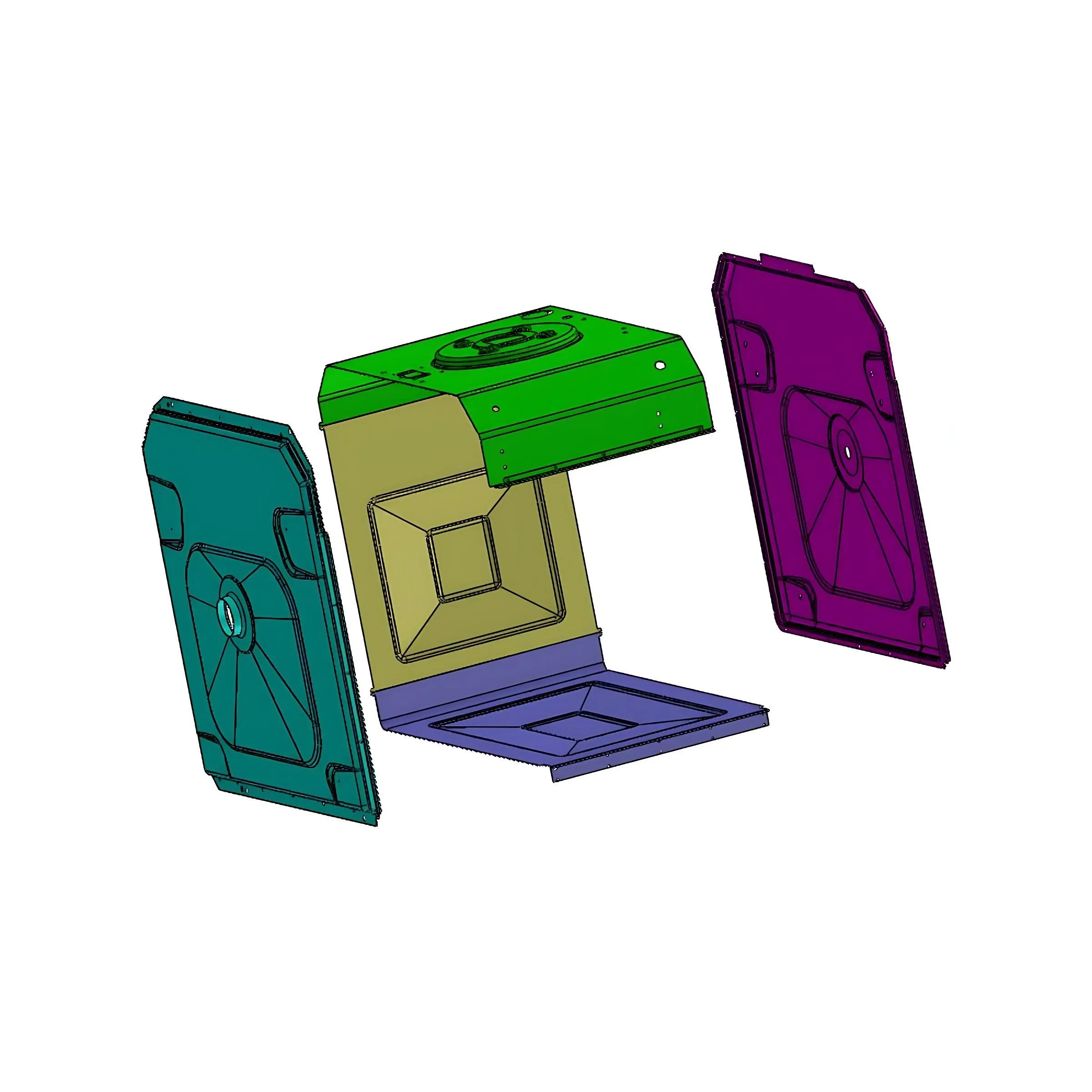

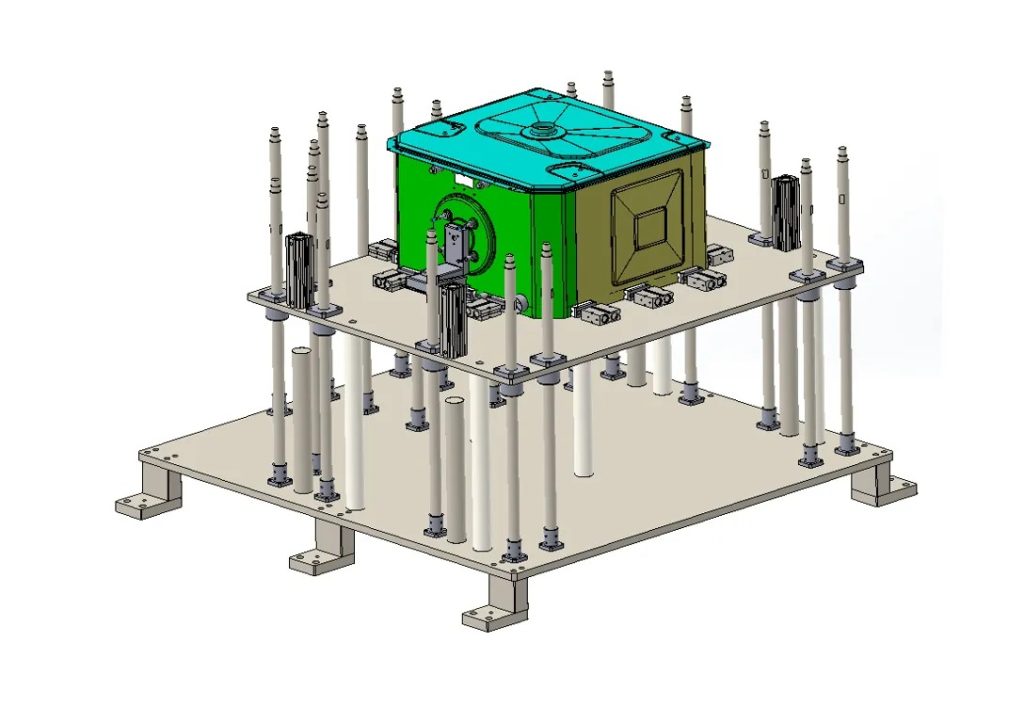

Developed by Innovation Laser, this laser welding solution is tailored for oven components. It features a three-sequence welding process, paired with dual positioning and adjustable structures to ensure precision and adaptability across various product needs.

Innovationlaser@zjcxlaser.com

1. Three-Step Welding Process: Clear Division of Labor, Precision and Efficiency

The solution adopts a three-step sequential welding process. Each step is tailored to address the welding needs of different parts, ensuring uniform weld seams and a sturdy structure:

- Step 1: Double Straight Seam Welding (approximately 160 seconds): Completes the core straight seam welding of components, laying a solid structural foundation.

- Step 2: Upper Part Welding (approximately 207 seconds): Focuses on welding the upper part of oven components to ensure sealing performance and load-bearing capacity.

- Step 3: Bottom Welding (approximately 207 seconds): Targets the key areas of the bottom for welding, enhancing overall stability.

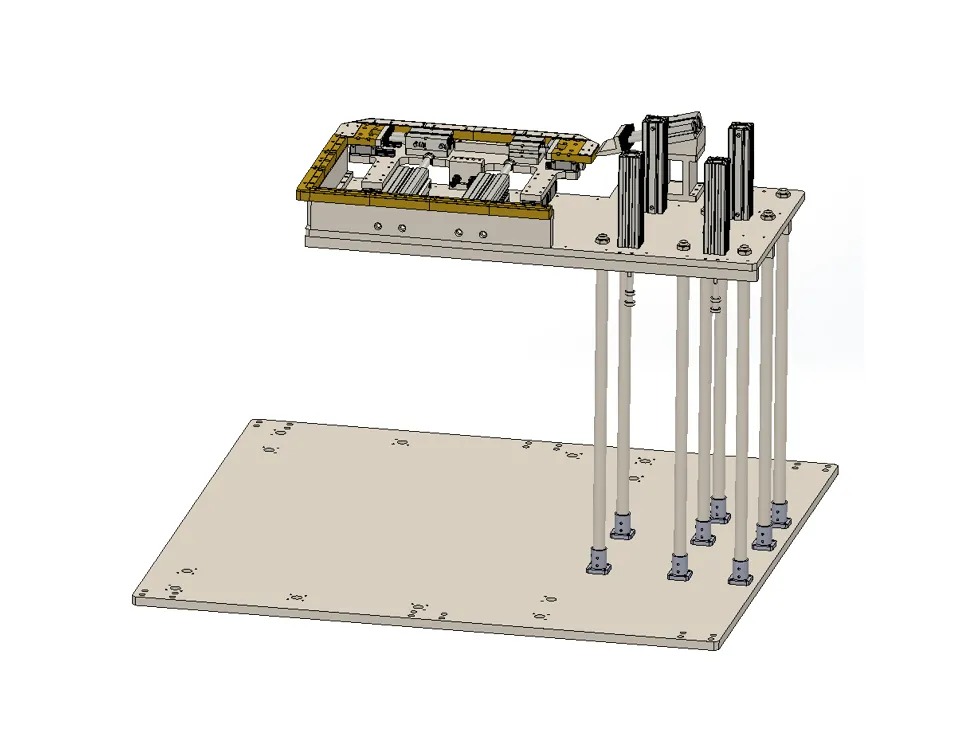

2. Core Technical Highlights: Positioning + Adjustment, Balancing Precision and Flexibility

- Dual Positioning Design: Combines inner fixture positioning and bottom positioning to effectively avoid welding deviation and improve weld seam precision.

- Multi-Dimensional Adjustment Structure: Equipped with upper and lower adjustment functions for the lower support plate, mold change auxiliary cylinders, support columns (auxiliary support during mold change), as well as height adjustment blocks for external pressure 1, external pressure 2, and internal pressure. It can easily adapt to the mold change needs of products with different sizes.

- Equipment Stability: Independently developed by Innovation Laser, the solution relies on a professional equipment layout to ensure a stable and reliable welding process.If your oven production is facing challenges such as difficulty adapting to multiple specifications, low welding efficiency, and insufficient precision, this laser welding solution may bring you a new approach!Feel free to leave a comment to discuss your production pain points, or contact Innovation Laser directly for a customized solution

If your oven production is facing challenges such as difficulty adapting to multiple specifications, low welding efficiency, and insufficient precision, this laser welding solution may bring you a new approach! Feel free to leave a comment to discuss your production pain points, or contact Innovation Laser directly for a customized solution.

01

Step

Submit Requirements

Provide drawings, photos, videos, and basic project details to help us quickly understand your needs.

02

Step

Technical Evaluation

Our team analyzes your materials and proposes the most suitable laser or automation solution.

03

Step

Design & Production

We finalize the solution, start detailed design, and manufacture the required equipment.

04

Step

Delivery & Support

We install the system, train your team, and provide ongoing technical service.

Contact

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.