About Laser

- Home

- > Inline Welding Solution: The Choice for Automated Precision Laser Welding

Inline Larse Welding Solution

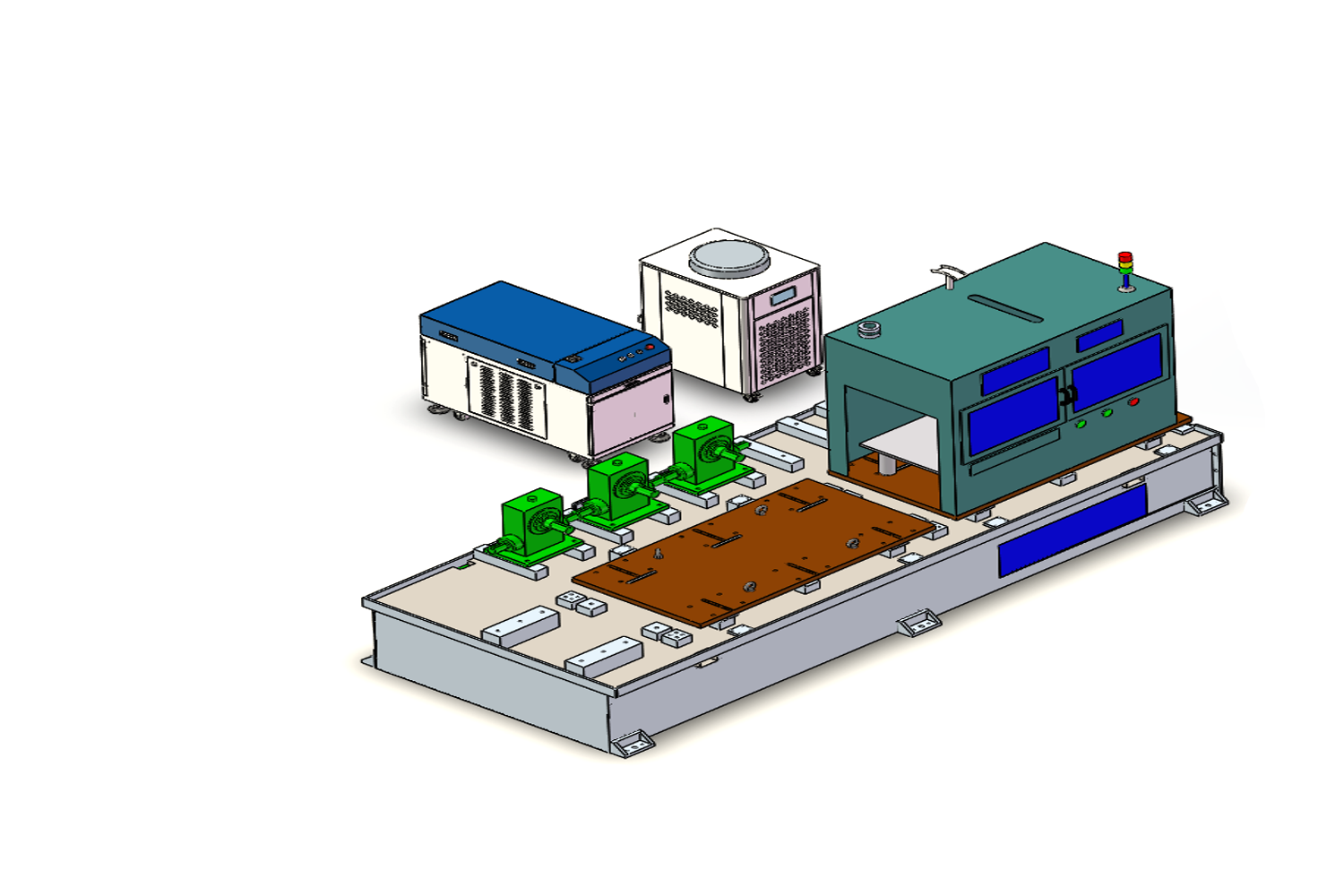

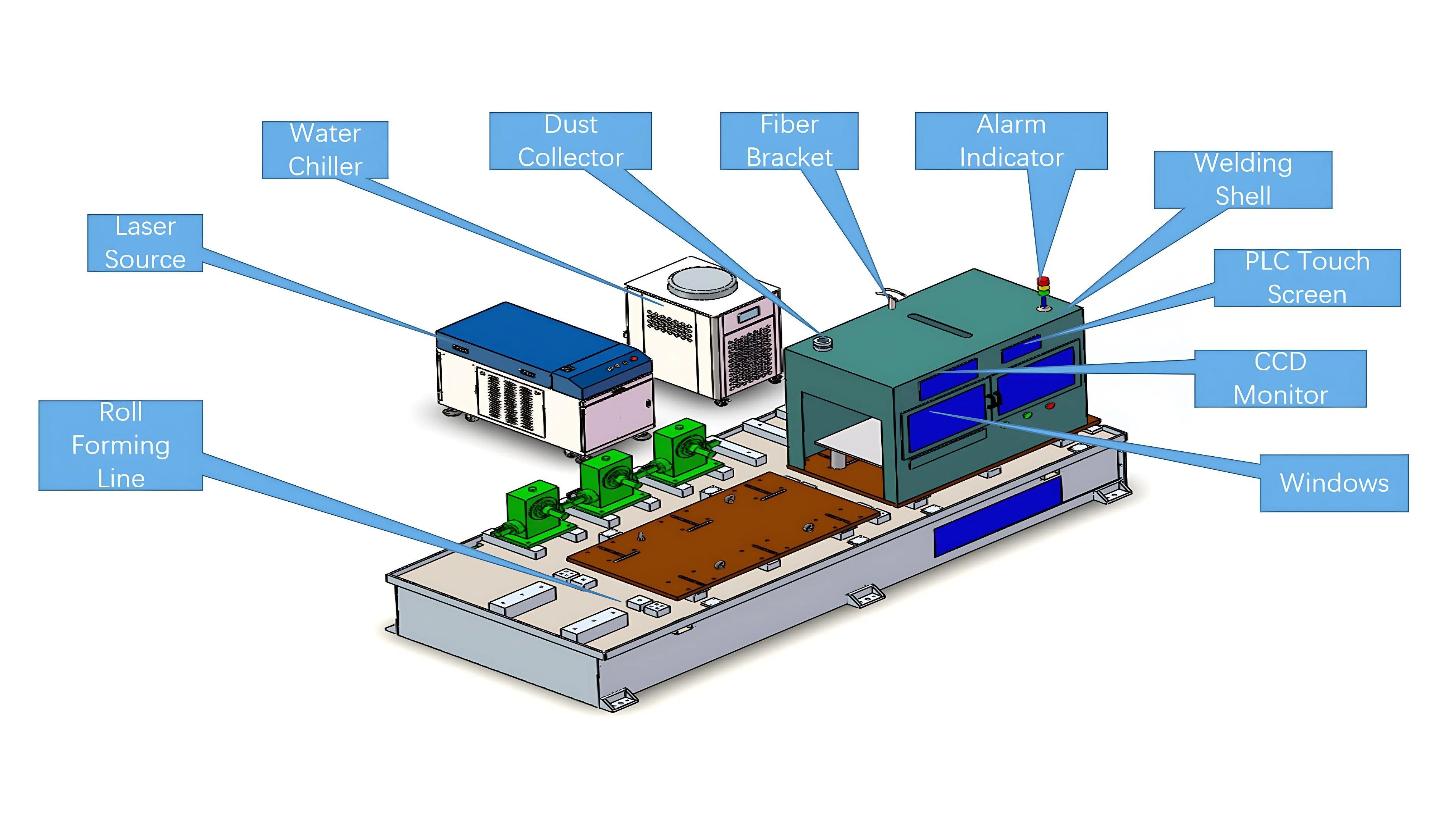

Core Product: Inline Welding Solution

- Core Configurations: Laser sources from IPG/Raycus/TRUMPF (3000w–8000w optional), Z/Y-axis adjustment modules (200mm stroke each), PLC touch screen, and CCD monitor.

- Key Advantages: Suitable for welding 1.5mm–4.5mm thick materials such as high-strength steel and galvanized sheets, with a maximum welding speed of 6.5m/min. It supports customizable configurations and seamless integration into existing production lines.

- Optional Accessories: Welding head protective cover, dust collector, and seam tracking function.

Comparison Dimension | Inline Laser Welding | Traditional Offline Laser Welding |

Process Connection | Integrated with production line; continuous forming-welding-subsequent processes | Discontinuous; workpiece transfer required |

Production Efficiency | High-beat continuous operation; 4-6.5m/min (metal); short-cycle (plastic) | Manual-dependent; low efficiency limited by transfer |

Quality Consistency | MES-linked; real-time monitoring; minimal batch errors | Manual parameter setting; batch deviations prone |

Space Requirement | Compact module; embedded into existing lines | Independent workshop/station; high space cost |

Applicable Scale | Large-scale mass production (e.g., Baosteel, home appliances) | Small-batch & customized production (samples, non-standard parts) |

Technical Essence: Integration of Production Line Integration and Welding Automation

- Physical Integration: Directly embed laser welding modules (e.g., welding heads, laser sources, monitoring systems) into the production line process. There is no need for manual transfer of workpieces to independent welding stations. For example, in Zhejiang Innovation Laser’s solution, the welding system can be linked with the roll forming line — workpieces directly enter the welding process after forming, reducing transfer time and errors.

- Data and Control Integration: Support connection with the production line’s central control system (e.g., Manufacturing Execution System, MES). It enables real-time calling of process parameters (e.g., laser power, welding speed) and real-time feedback of welding process data (e.g., weld depth, temperature). For instance, Germany’s LPKF InlineWeld 6200 connects to the customer’s MES via the ProfiNet interface, automatically receiving production tasks and outputting quality monitoring data to meet the intelligent requirements of Industry 4.0.

Inline Laser Welding is not a single “welding technology”, but a technical solution system centered on “production line integration”. Through physical embedding, data linkage and automatic control, it solves the pain points of “low welding efficiency, poor consistency and disjointed processes” in large-scale production, and is a key technical direction for realizing automated and intelligent welding in modern manufacturing (especially in automotive, steel, electronics and medical industries).

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.