About Laser

- Home

- > Hybrid Laser-MIG Welding: An efficient process option for welding medium-thick plates.

Hybrid Laser-MIG Welding for welding medium-thick plates.

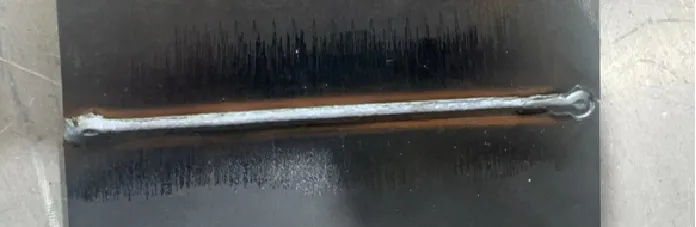

Hybrid laser-arc welding is a high-efficiency welding method that integrates arc welding (e.g., MIG welding) with laser welding simultaneously. It leverages the laser’s high energy density for deep penetration and fast welding, plus the arc’s excellent gap-bridging ability for stable molten pool formation. This technology offsets the drawbacks of single processes—solving laser welding’s strict fit-up requirements and arc welding’s limited penetration depth. Ideal for welding high-strength steel, aluminum alloys, and other structural materials, it is widely used in industrial automation, automotive, and aerospace fields.

Innovationlaser@zjcxlaser.com

Core Advantages

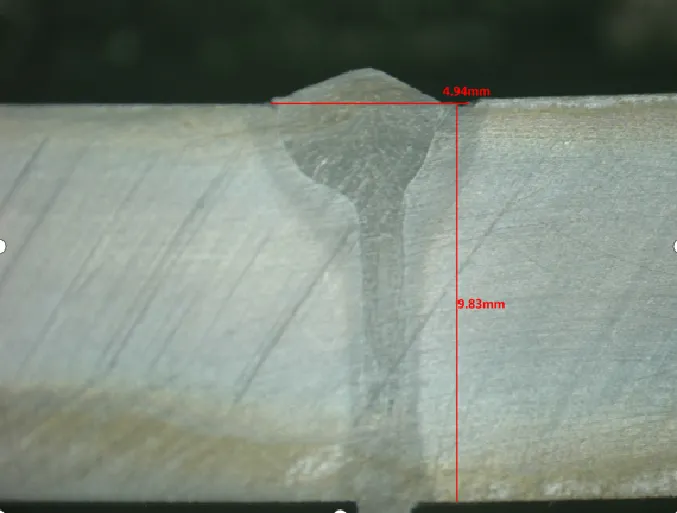

- The laser’s deep penetration capability and high-speed welding characteristics, which form an extremely narrow heat-affected zone, enabling low heat input and low-distortion welding.

- The arc’s gap-bridging ability (aided by filler wire), weld slow-cooling effect, and metallurgical property adjustment function, which optimize weld quality.

Specific technical advantages include:

- Significantly improved joint fit-up tolerance (under real-time adaptive control, the tolerance can be several times greater than that of laser welding alone).

- Avoidance of hot cracking (shrinkage cracks formed during the solidification of weld metal), enhancing weld quality.

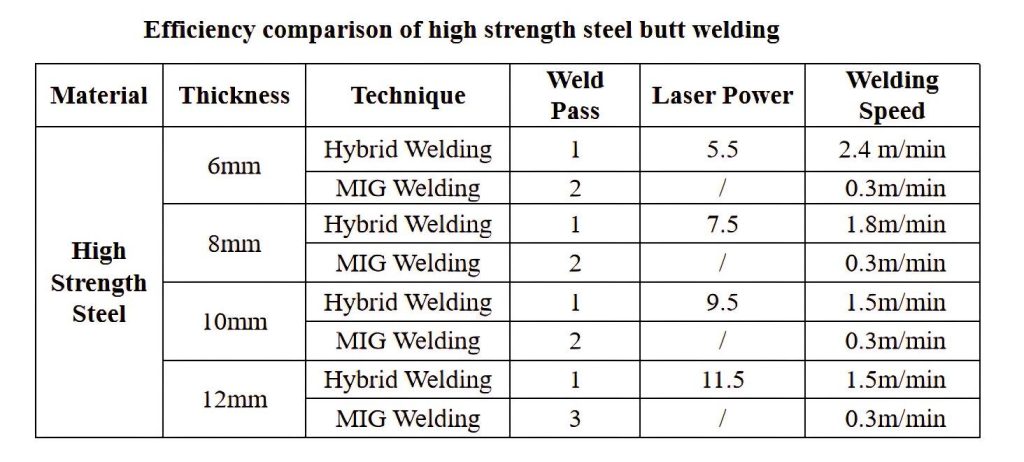

- Remarkable increase in single-pass weld penetration depth and welding speed.

- Reduced heat input and deformation, eliminating the need for subsequent correction processes.

- No pre-welding preparation required, facilitating easy automation.

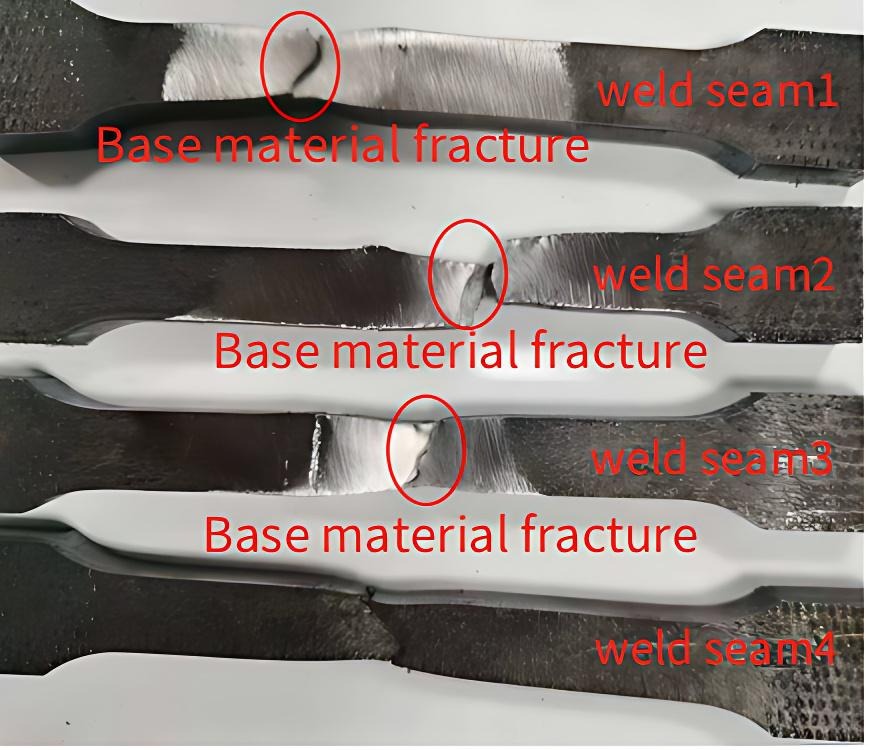

| Tensile Strength MPa | |

| Base Material | 427 |

| Welds 1 | 406 |

| Welds 2 | 420 |

| Welds 3 | 405 |

Application Scenarios

Its process characteristics make it suitable for several important industrial fields:

- Bridges, shipbuilding, container manufacturing, automobile production, rail transit, oil pipelines, etc.

- Capable of achieving single-sided welding with double-sided forming for medium-thick plates (6-20 mm) and extra-thick plates (over 20 mm) in a single pass.

Industrial Application Value

- Automobile Manufacturing: Improves welding speed and reliability on high-production assembly lines. The relaxed fit-up tolerance reduces the time spent on material preparation.

- Shipbuilding/Rail Transit: Compared with traditional processes such as Metal Active Gas (MAG) welding and Submerged Arc Welding (SAW), it features lower heat input and less deformation, eliminating the need for distortion correction and rework, thus significantly reducing overall manufacturing costs.

- General Advantages: Shortens overall welding time to further control production costs, and is suitable for complex requirements such as thick plate welding.

01

Step

Submit Requirements

Provide drawings, photos, videos, and basic project details to help us quickly understand your needs.

02

Step

Technical Evaluation

Our team analyzes your materials and proposes the most suitable laser or automation solution.

03

Step

Design & Production

We finalize the solution, start detailed design, and manufacture the required equipment.

04

Step

Delivery & Support

We install the system, train your team, and provide ongoing technical service.

Contact

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.