About Laser

- Home

- > Customized Robotic Laser Welding Solution for Condenser & Low-Temperature Radiator Assemblies

Laser Welding Solution for Condenser & Low-Temperature Radiator Assemblies

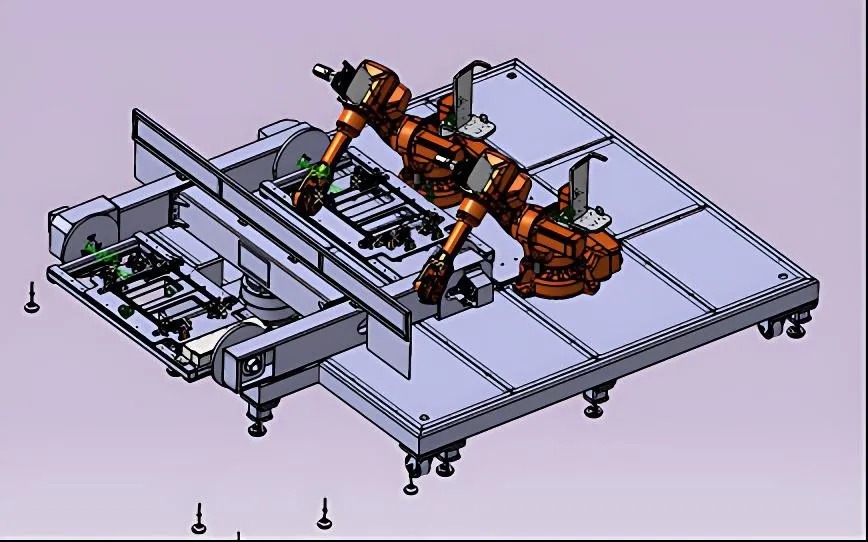

Manufacturing condenser assemblies and low-temperature radiator requires high weld density, consistent joint quality, and strict dimensional control. Traditional welding methods often struggle with deformation and low production consistency when facing multi-point, short-seam welding tasks. To address these challenges, Truesyn developed a customized robotic laser welding station specifically designed for T05 condenser pull rods and low-temperature radiator assemblies.

1. Solution Overview

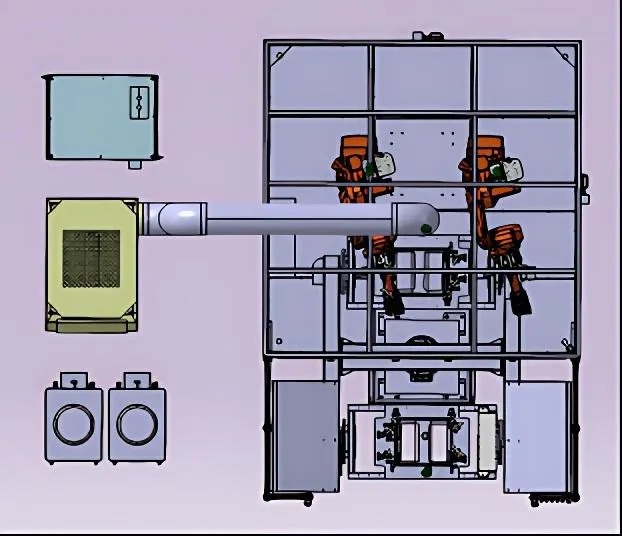

This solution is built around a robot-guided fiber laser welding station with dual A/B fixtures and a three-axis positioner, optimized for high-density welding points within limited floor space.

1.1 Key Technical Configuration (Project-Specific)

- Robot: ABB IRB2600-20/165

- Positioning system: Three-axis positioner with dual A/B fixtures

- Laser welding system: Fiber laser with wire feeder

- Process support: Integrated chiller and fume extraction system

- Control system: PLC-based centralized control

This configuration enables continuous production, where one fixture is welded while the other is prepared, minimizing idle time and improving overall utilization.

1.2 Precision Fixturing: A Key Differentiator

Unlike generic welding stations, this solution uses multi-directional clamping fixtures specifically designed for condenser and radiator geometries, including:

- Side push clamping for lateral positioning

- Bottom clamping to prevent vertical movement

- Fixed datum blocks to control assembly reference points

- Rigid base structure to eliminate vibration during welding

This fixture architecture ensures stable positioning for all weld points, significantly reducing cumulative tolerance errors—an issue often overlooked in standard laser welding solutions.

2. Process Advantages in Real Production

- High weld consistency- All seams are welded under identical conditions.

- Reduced deformation- Concentrated laser heat input minimizes thermal distortion compared to arc welding.

- Compact footprint- Total station layout approximately 5.2 m × 4.5 m, covering only ~23 m², suitable for space-constrained workshops.

- Efficient changeover: Standardized locating pins enable fast fixture replacement between product variants.

3. Why This Solution Stands Out

Most laser welding solutions emphasize laser power or robot brand alone. Truesyn’s project demonstrates that fixture design, positioning strategy, and weld-point density management are equally critical for real production success.

By combining:

- product-specific weld distribution analysis,

- customized fixturing geometry,

- and synchronized robot-positioner motion,

This solution delivers production-ready laser welding, not just laboratory-level welding performance.

4. Conclusion

Truesyn’s customized laser welding station provides a reliable and scalable solution for condenser and low-temperature water tank manufacturing. It is particularly suitable for applications requiring multiple short weld seams, tight dimensional control, and high production stability. By integrating precision fixturing with robotic laser welding, manufacturers can achieve higher consistency, lower rework rates, and improved long-term production reliability.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.