About Laser

- Home

- > Laser Welding Solution for Cooling Manifold in AI Server

Laser Welding Solution for Cooling Manifold in AI Server

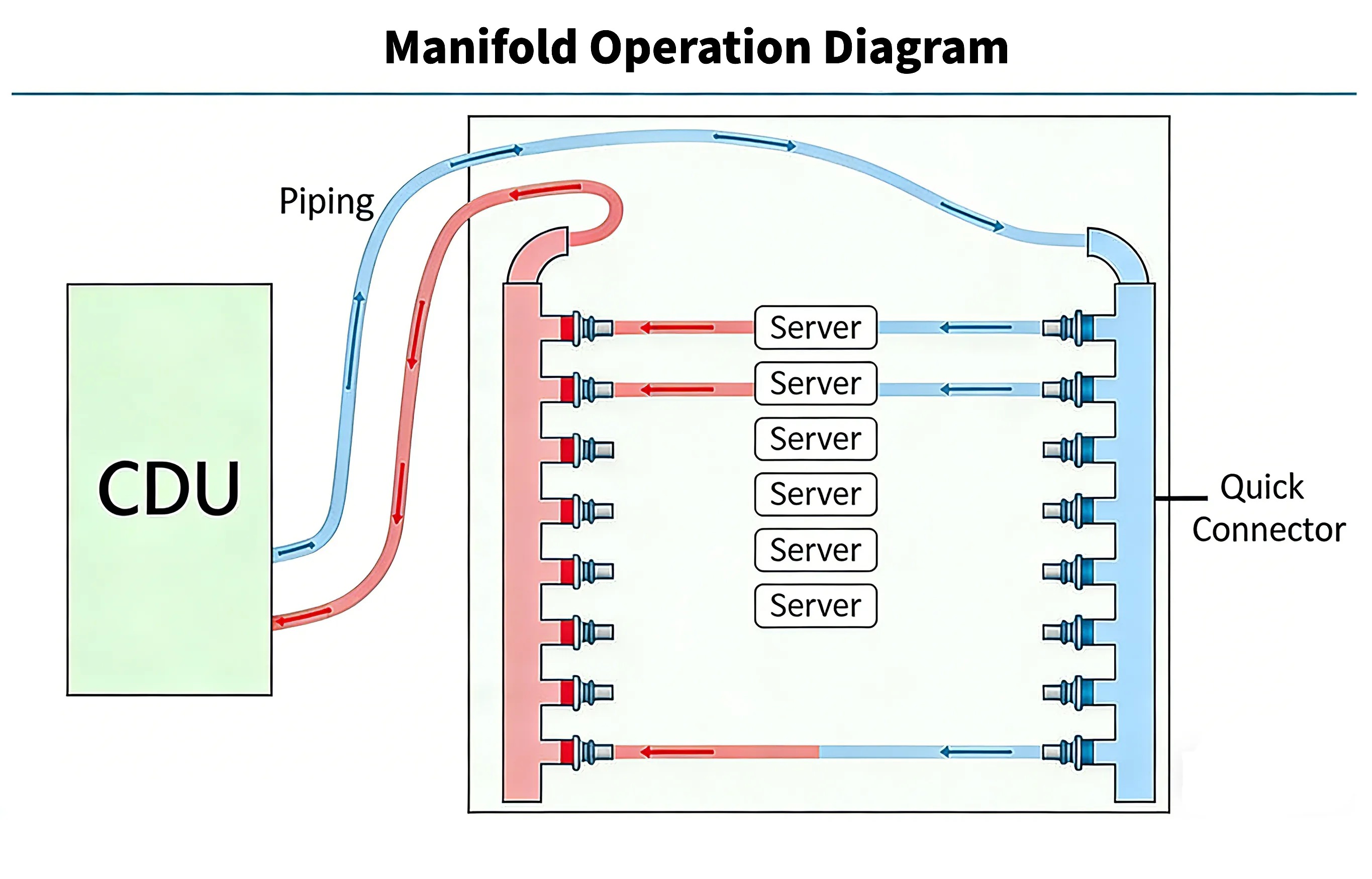

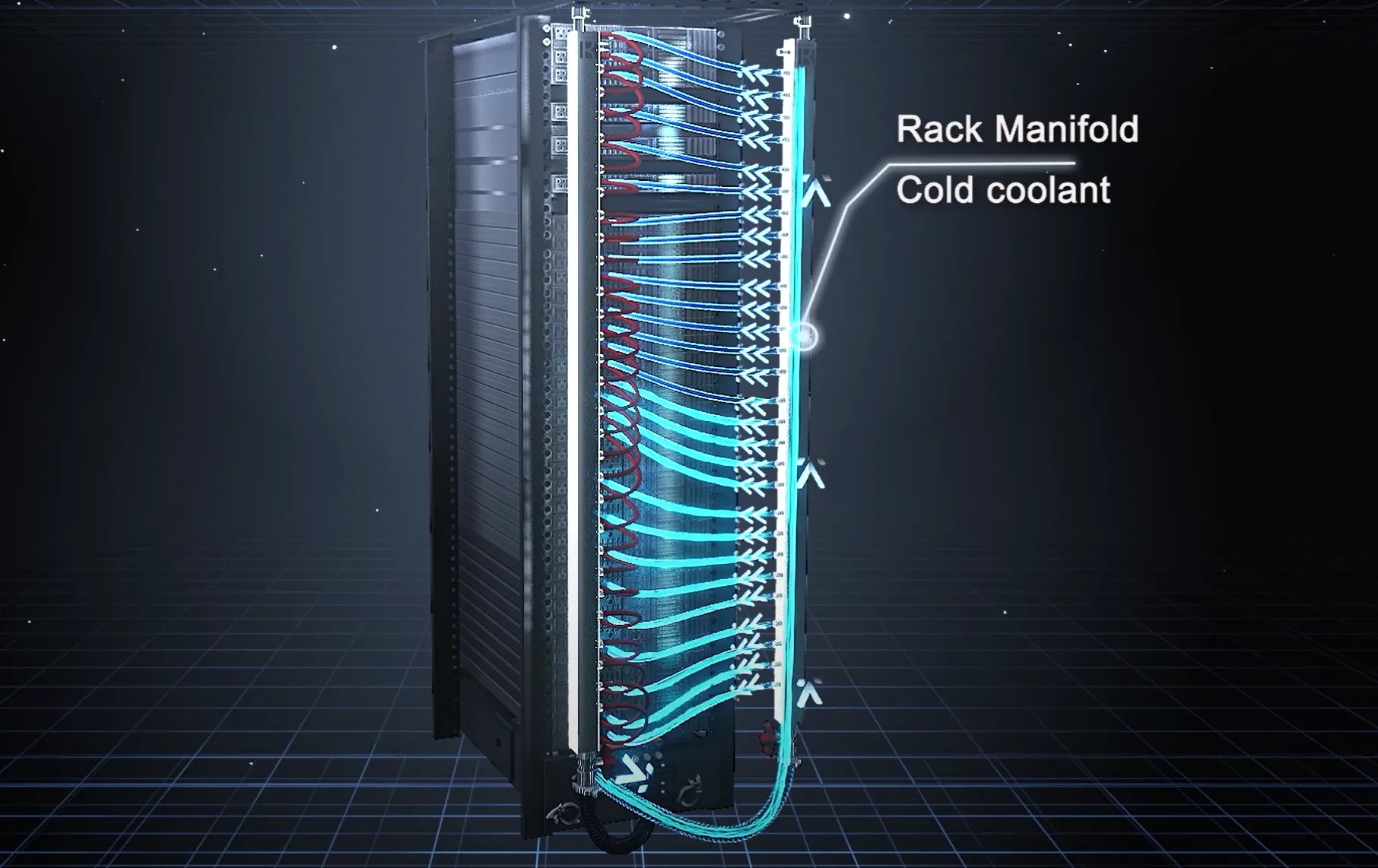

Manifold :A core distribution component connecting the CDU (Coolant Distribution Unit) and cold plates in liquid cooling systems. Installed inside cabinets, it distributes cooling fluid evenly to each heat dissipation unit, ensuring stable operation of high-performance computing equipment. Suitable for AI servers, high-density data centers, and other scenarios.

- Strong Corrosion Resistance: Crafted from specialized corrosion-resistant materials, it is compatible with various cooling fluids long-term, maintaining structural integrity and heat dissipation performance under complex conditions while preventing fluid contamination or leakage caused by corrosion.

- High Structural Strength: Boasts excellent pressure and impact resistance, stably withstanding the operating pressure of cooling systems and external impacts in data center environments to ensure long-term safe system operation.

- Flexible Structural Designs: Available in single-row, double-row and other configurations, it adapts flexibly to data center server layouts and heat dissipation requirements, enhancing system installation compatibility.

- Ultra-High Manufacturing Precision: Adopts advanced precision manufacturing processes to ensure uniform distribution of cooling fluids to each server or device, avoiding local insufficient heat dissipation due to uneven distribution and guaranteeing consistent cooling efficiency.

I.Key Functions

- Distribute cooling capacity evenly to avoid equipment overheating and performance throttling;

- Support online maintenance, reducing downtime losses;

- Collaborate with CDU to guarantee efficient operation of the liquid cooling system.

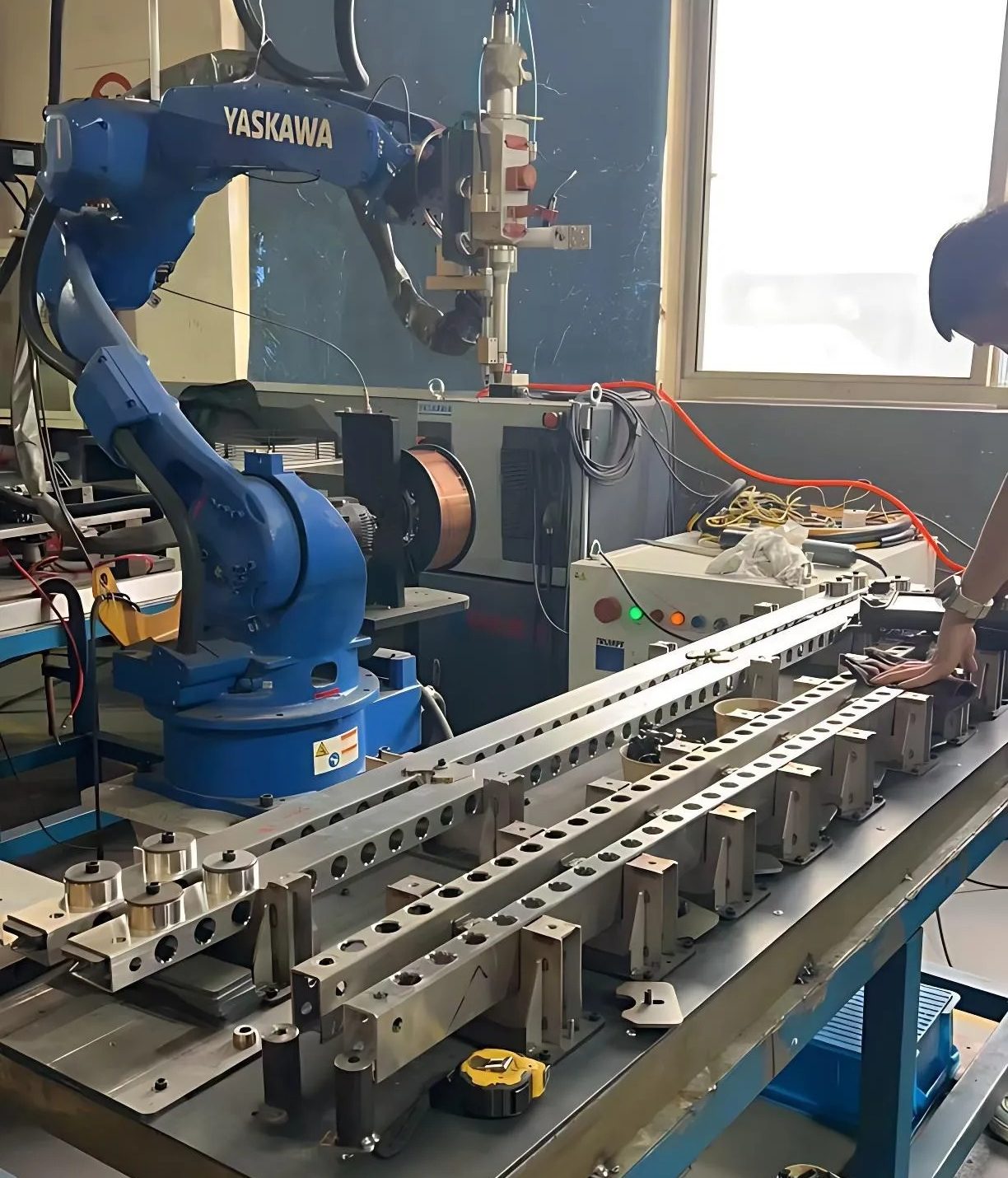

II. Basis for Selecting Laser Welding

III. Adaptability Between Laser Welding and Product

- Material Adaptability: Low heat input preserves the corrosion resistance of stainless steel, meeting the 10-year service life requirement;

- Sealing Compliance: Weld leakage rate ≤ 1×10⁻¹⁰ Pa·m³/s, satisfying fluid sealing demands;

- Precision Matching: Minimal deformation ensures flow deviation ≤ 5% and flow channel dimensional accuracy;

- Structure Adaptability: Compatible with complex joints of single/double-row tubes, supporting automated mass production with strong consistency.

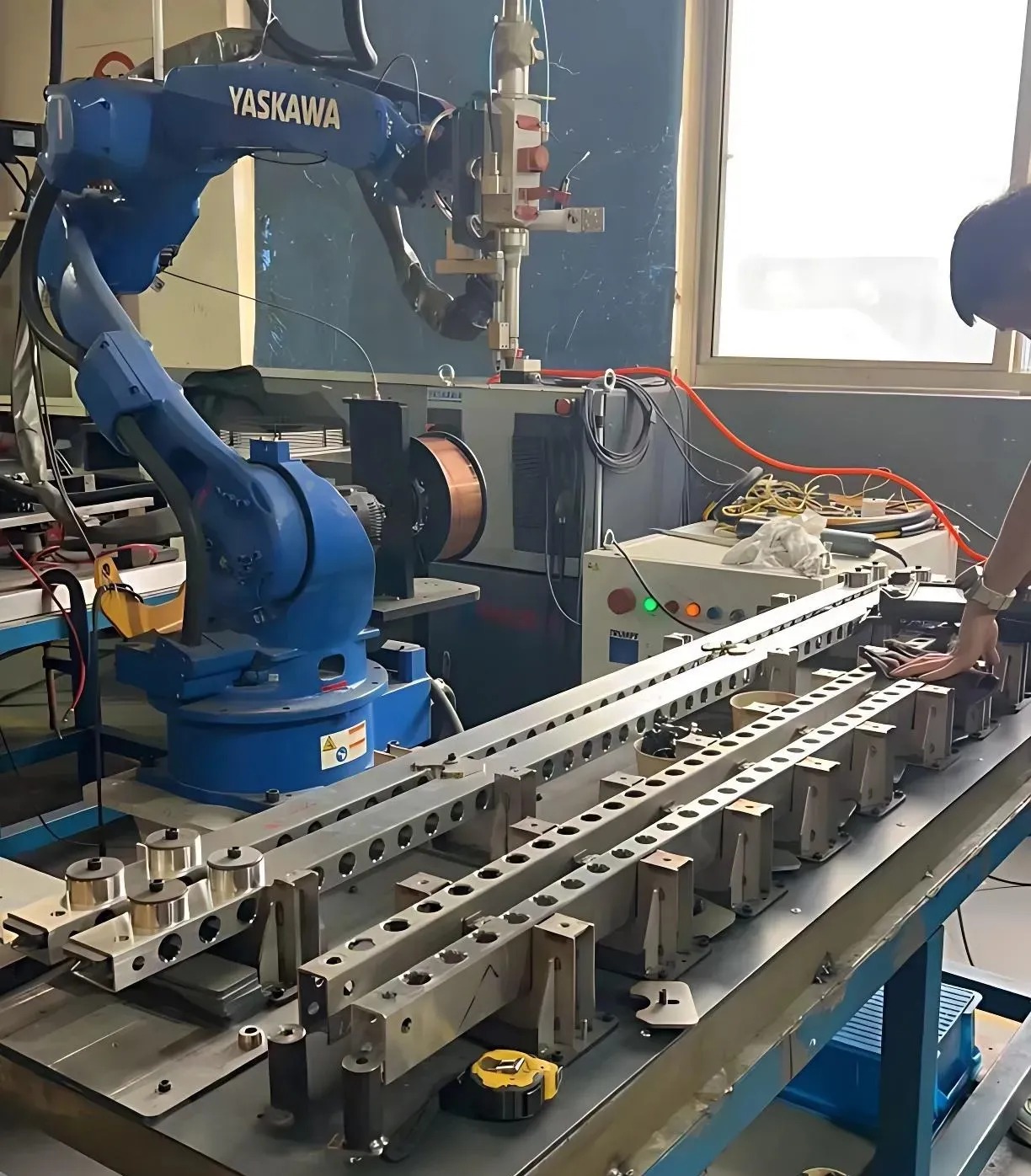

IV. Core Impacts of Laser Welding on the Product

- Ensure Heat Dissipation Stability: Maintain flow uniformity to prevent equipment performance throttling;

- Extend Service Life: Weld corrosion resistance matches the base material, meeting long-term operation needs;

- Reduce Leakage Risk: Strict sealing standards, combined with integrated design, can reduce leakage by over 70%;

- Support Upgrading and Iteration: Adapt to future technological trends such as triple-row tubes and intelligent sensor integration.

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.