About Laser

- Home

- > Programming-Free Welding Robot System

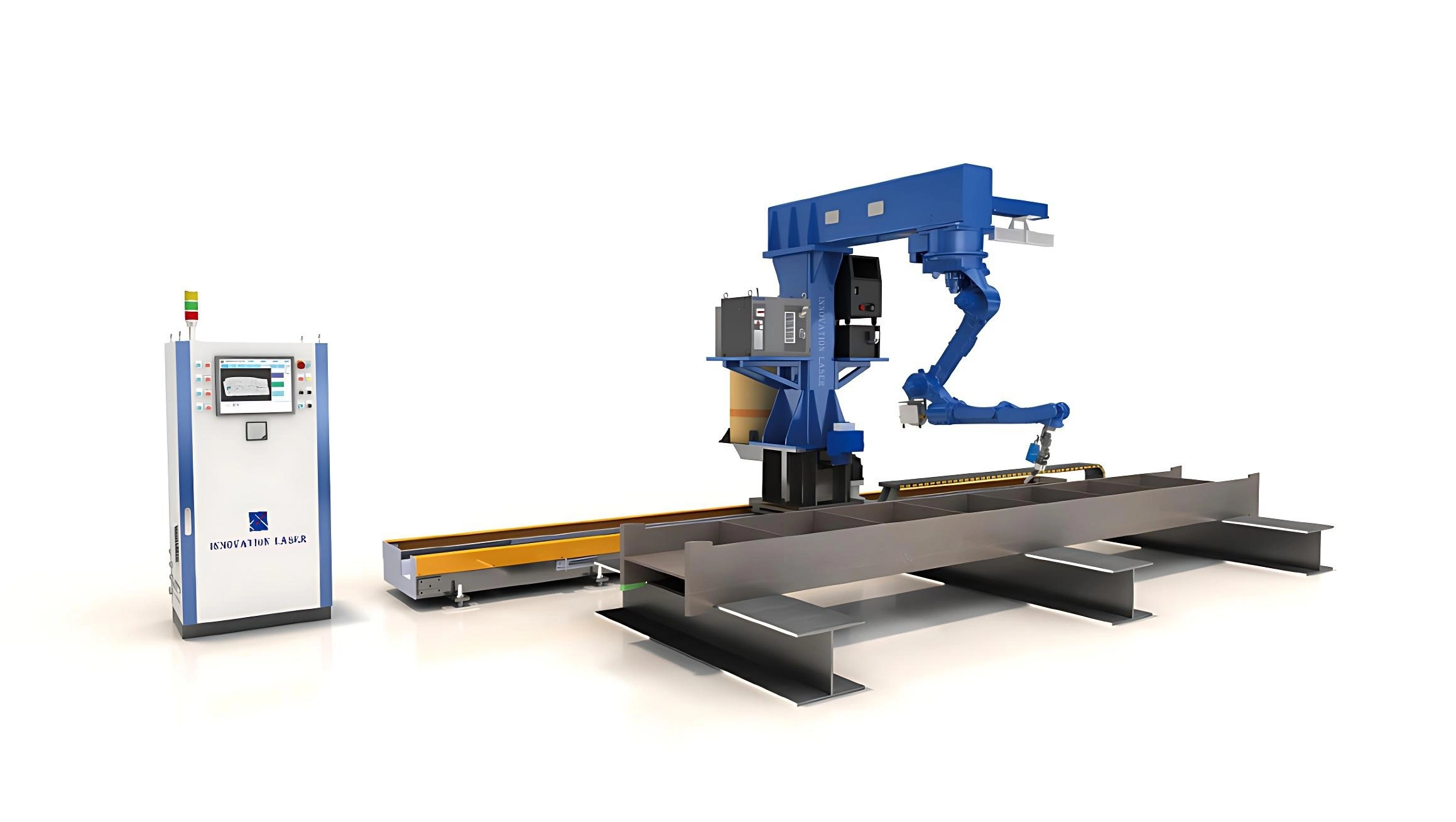

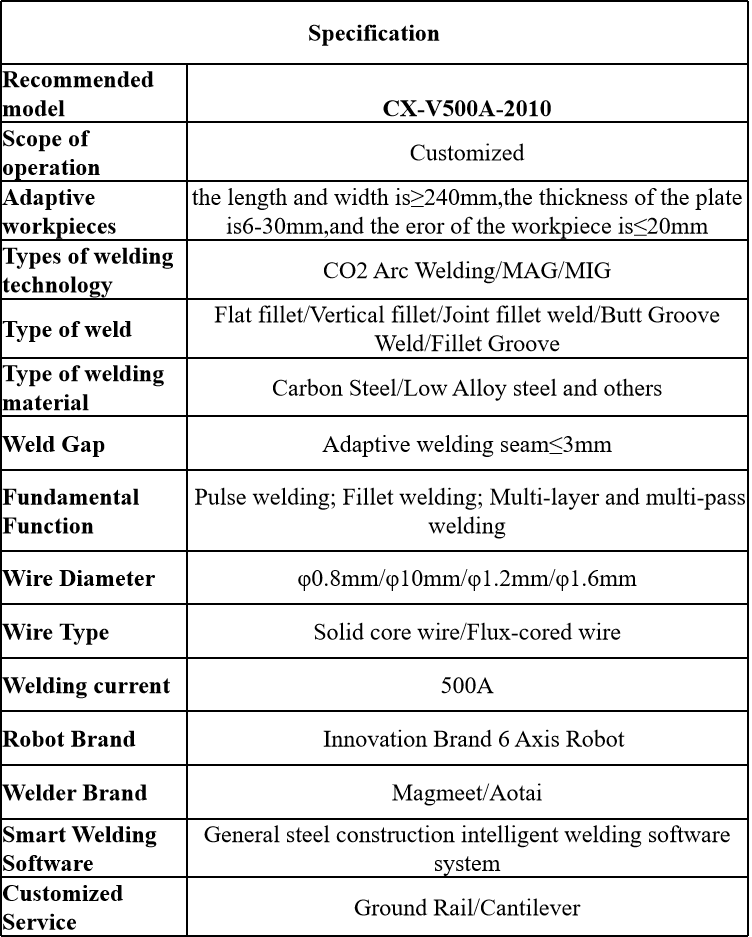

Programming Free Welding Robot System

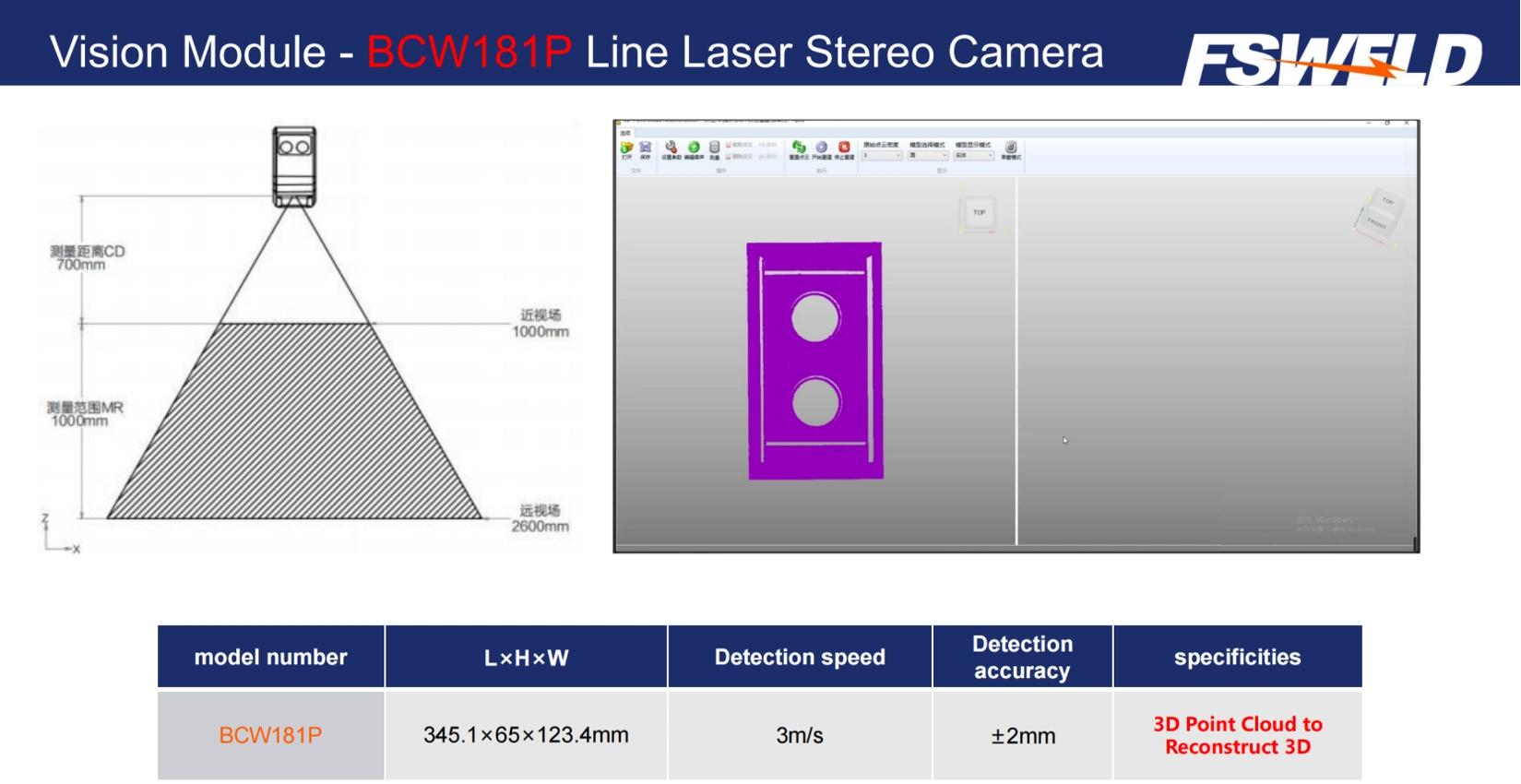

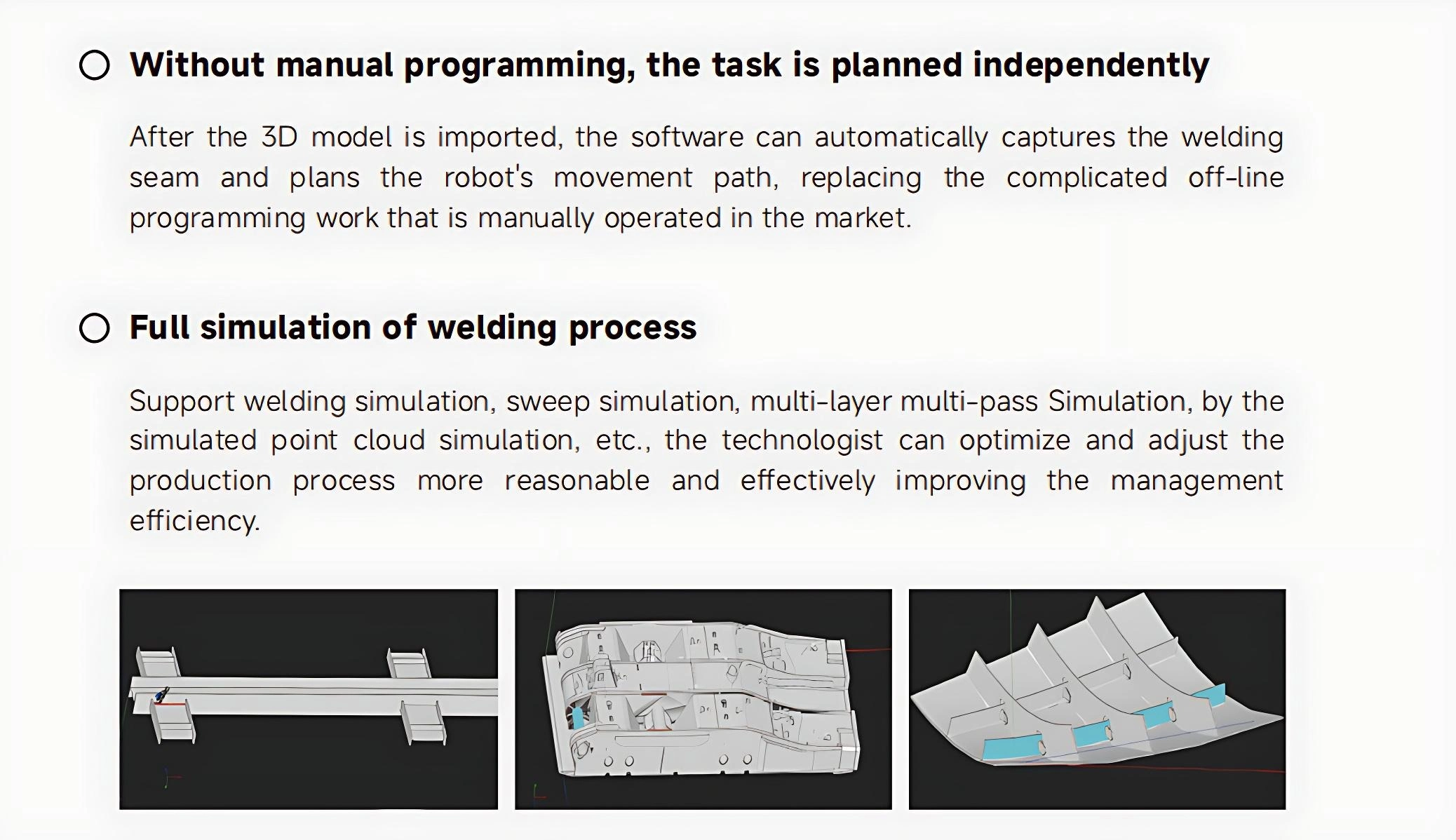

It frees manufacturer from complicated programming , using 3D camera or

- importing the 3D drawings(STP file) , robot will recongnize the welding path; Automatic calibration function can further shorten the time of robot equipment admission configuration and maintenance calibration, start the welding operation quickly.

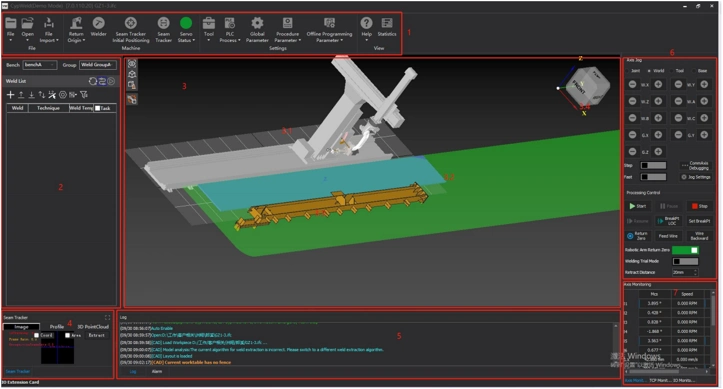

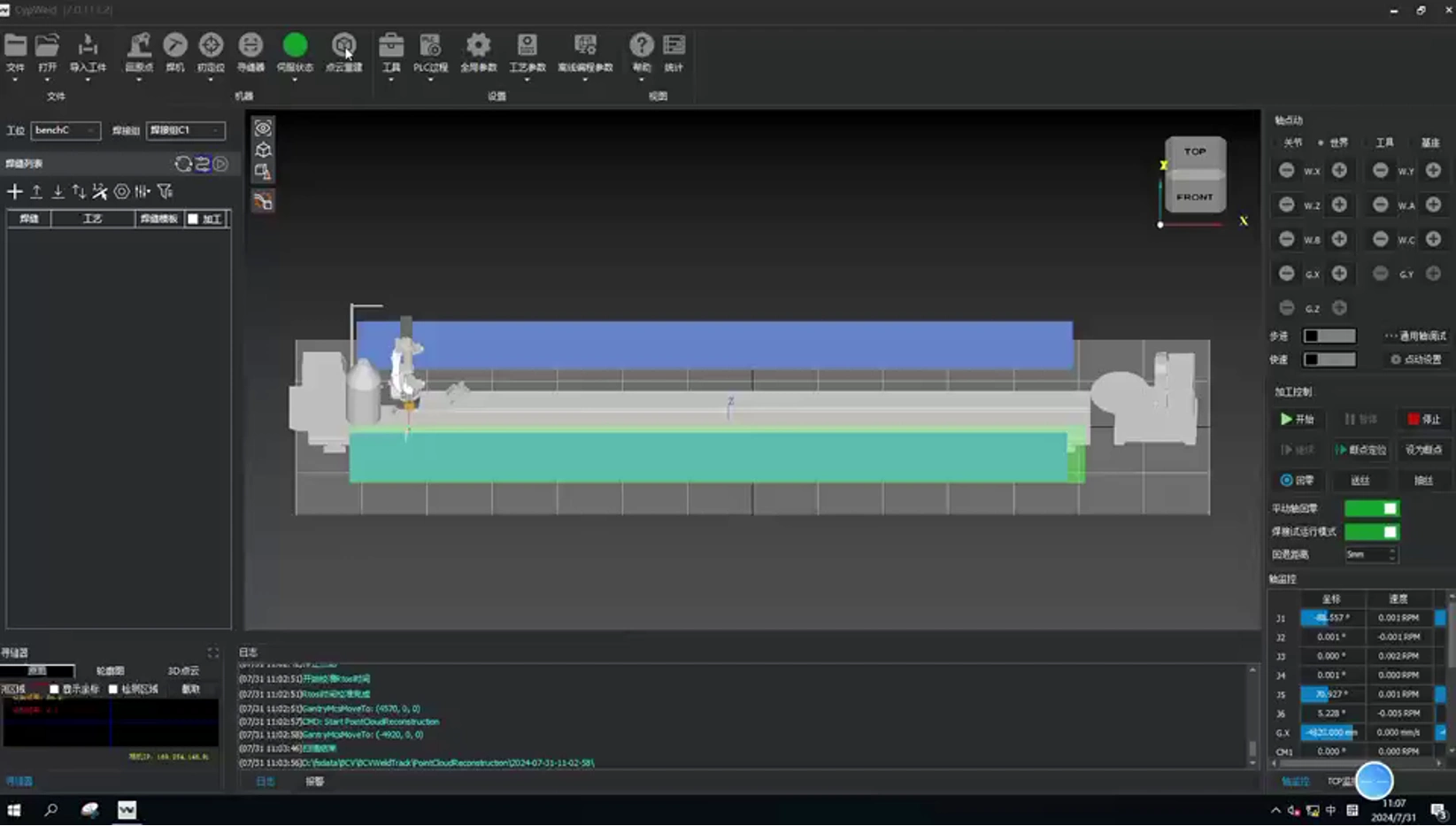

Technical support-Intelligent welding software system

The software adopts a digital twin system and is driven by models. Smoothly interface with mainstream 3D modeling software such as Tekla and SolidWorks

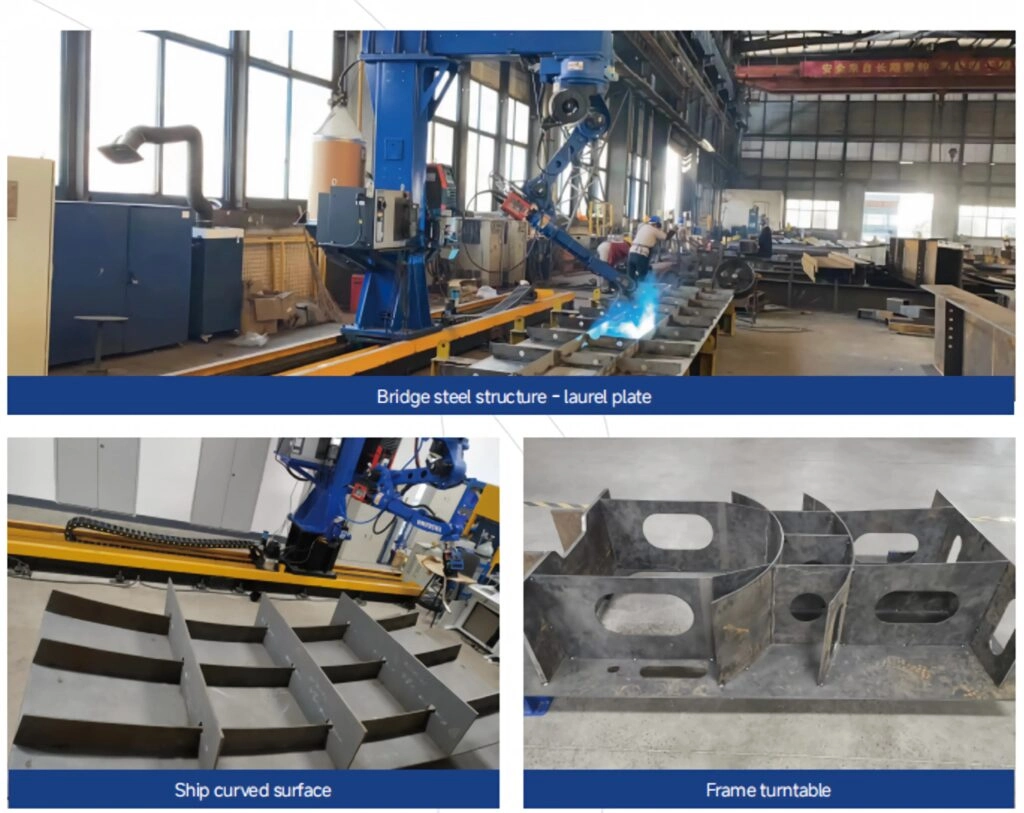

Application:

Bridge steel structure; Construction steel structure, Shipbuilding, Pressure vessels, Heavy machinery and other varieties

Advantage :

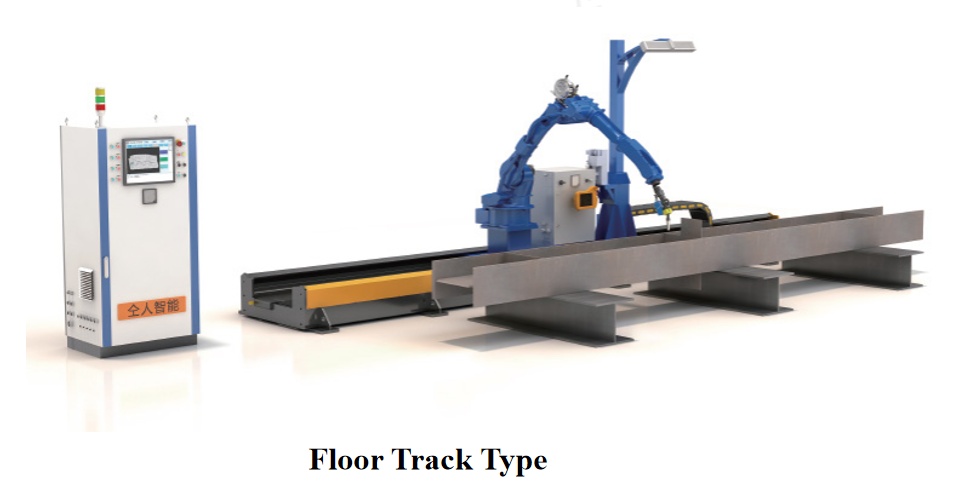

1.Multi-type small batch mixed welding It can simultaneously mixed welding with different kinds and small batches of workpieces in the same working area. 2.Extra long workpiece welding capability; By adopting track/rail , it can achieve long workpeice welding easily

Submit Requirements

Technical Evaluation

Design & Production

Delivery & Support

Reliable After-Sales Service You Can Trust.

Our service team offers quick troubleshooting, remote assistance, on-site support, and lifetime technical guidance to keep your production stable and efficient.

Email Address

Company Address

Building 1, Wanli Science&Innovation Industrial Park, 104 National Road, Shangyu District, Shaoxing, Zhejiang, China,312300

Opening Hour

Monday to Friday: 9:00 AM to 7:00 PM Saturday to Sunday: 9:00 AM to 5:00 PM

Get in Touch

Tell us your needs — we’ll reply soon.